Providing device and method of LED wafers

A wafer and positioning device technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of low precision, high labor consumption, low productivity, etc., to reduce manufacturing costs, reduce the ratio of inferior quality, The effect of reducing engineering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical configuration of the LED wafer supply device will be described in detail below with reference to the drawings.

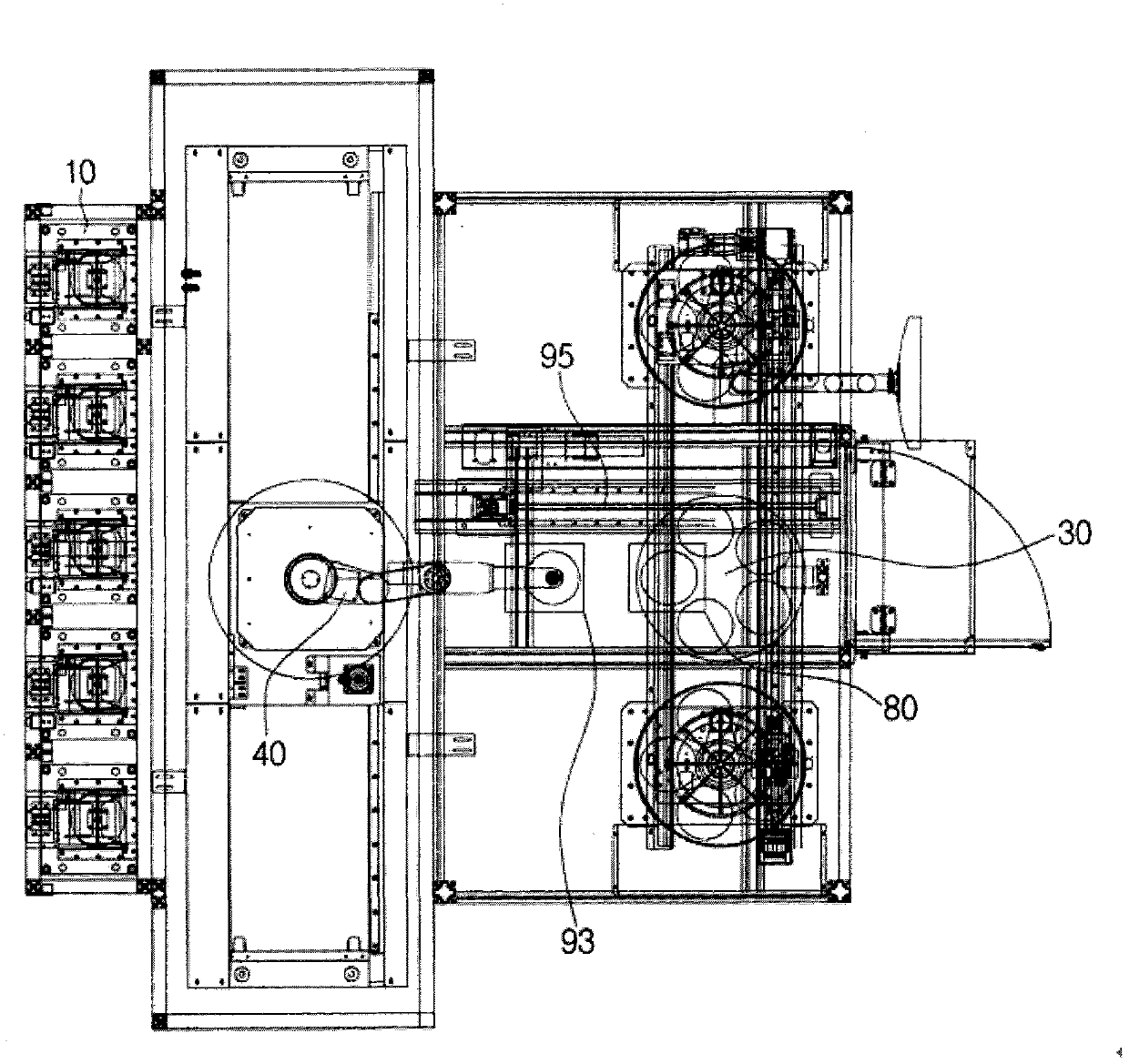

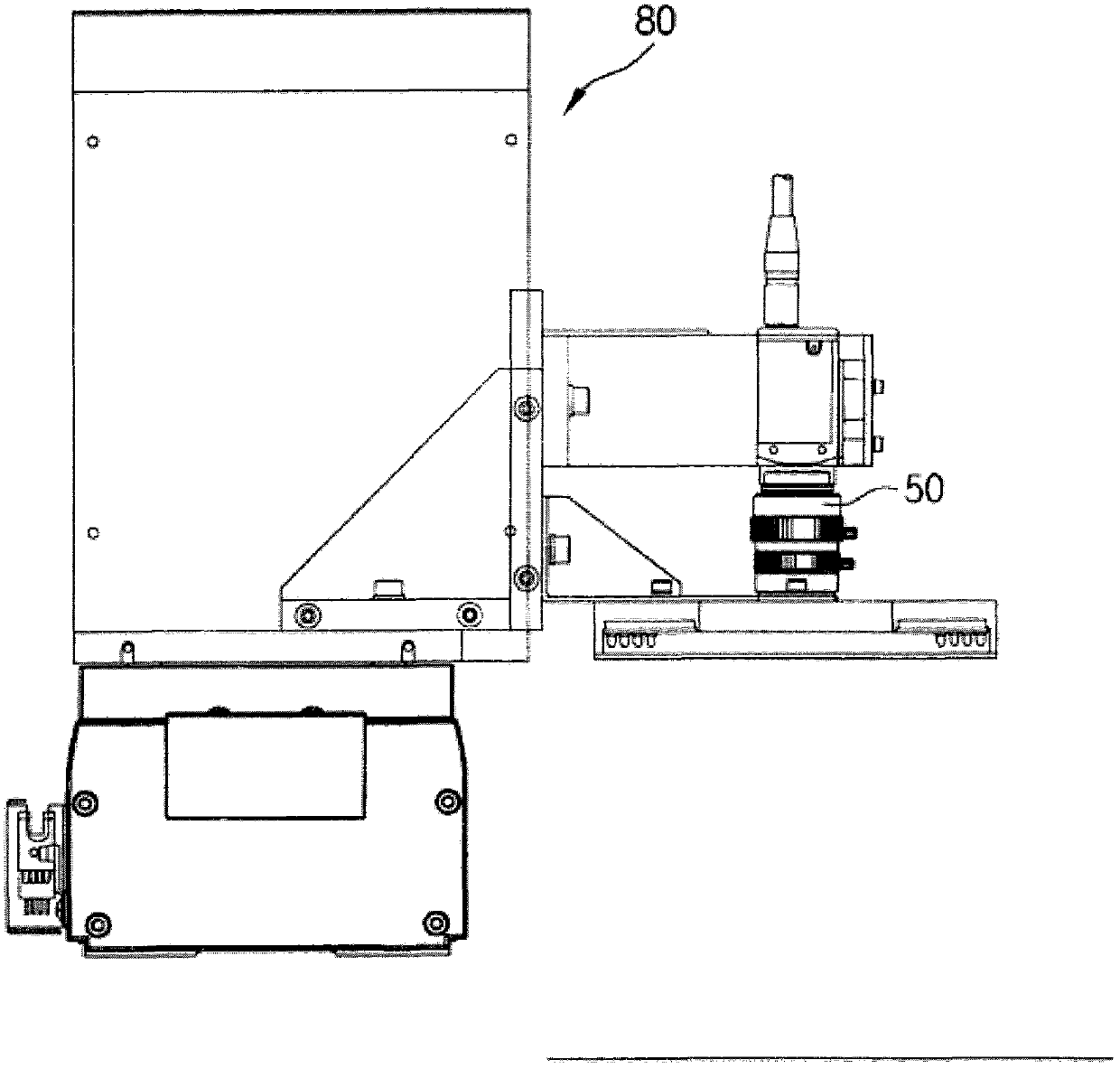

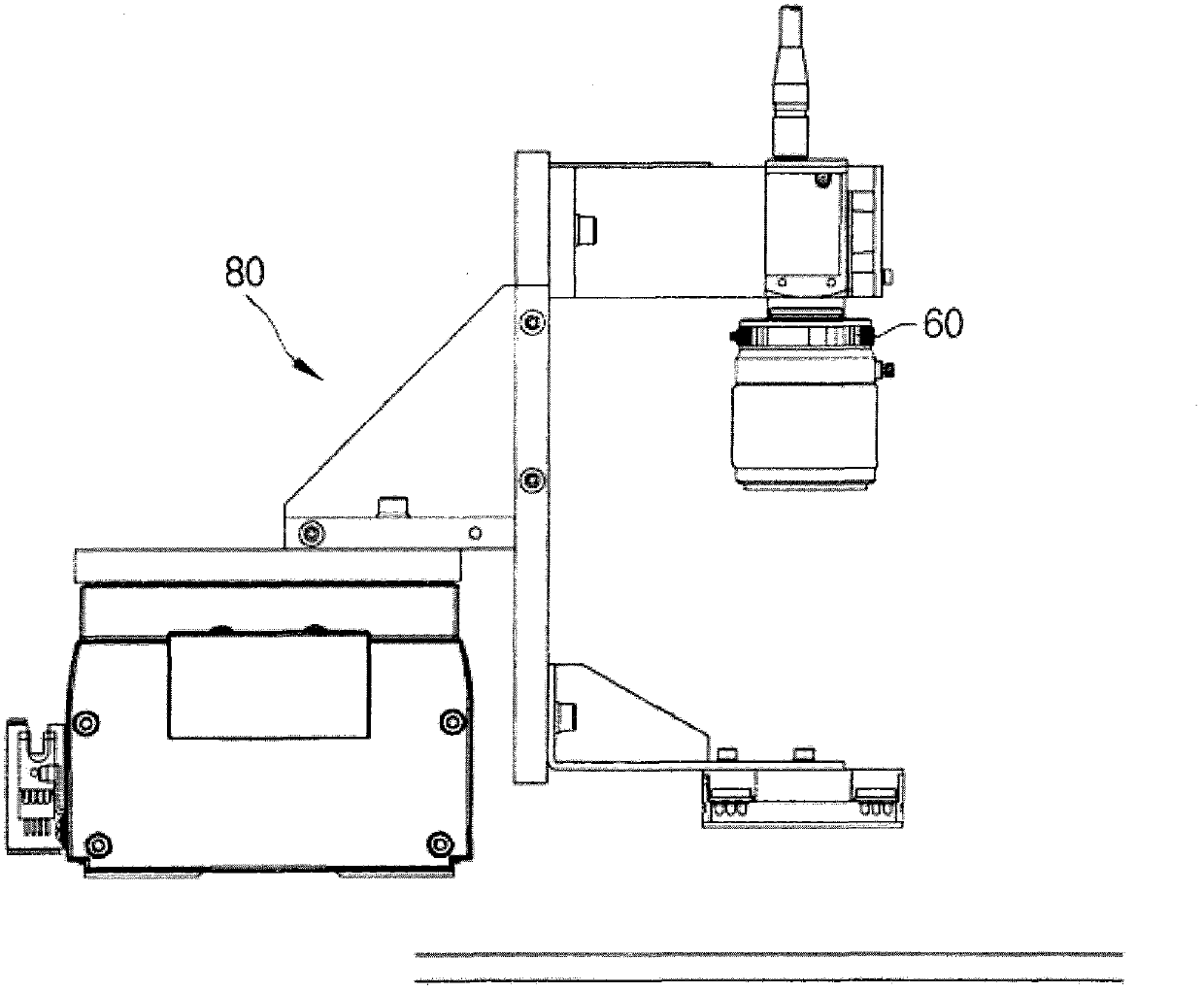

[0034] Such as Figure 1 to Figure 6 As shown, an LED wafer providing device according to an embodiment of the present invention includes a deck 10 , a carrier 30 , an arrangement unit 93 , a transfer robot 40 , a positioning device 20 , a camera unit 80 , and an LED wafer loading robot 95 . The cassette 10 is installed with a plurality of LED wafers 99 for loading; the carrier 30 is equipped with a plurality of containers 31 for arranging the LED wafers 99; the carrier 30 is formed in a disc shape, and the containers 31 are equipped radially. There are a plurality of them, and they are spaced apart at regular intervals in the circumferential direction based on the center of the disc-shaped carrier 30 .

[0035] The alignment unit 93 aligns the LED wafers 99 to be placed on the carrier 30 . In this case, the alignment of the LED wafer 99 is to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap