Sugarcane leaf stripping device

A technology for peeling leaves and sugarcane, which is applied in the field of sugarcane harvester manufacturing, can solve the problems of low leaf stripping efficiency and low cleanliness, and achieve the effect of increasing income and improving leaf stripping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

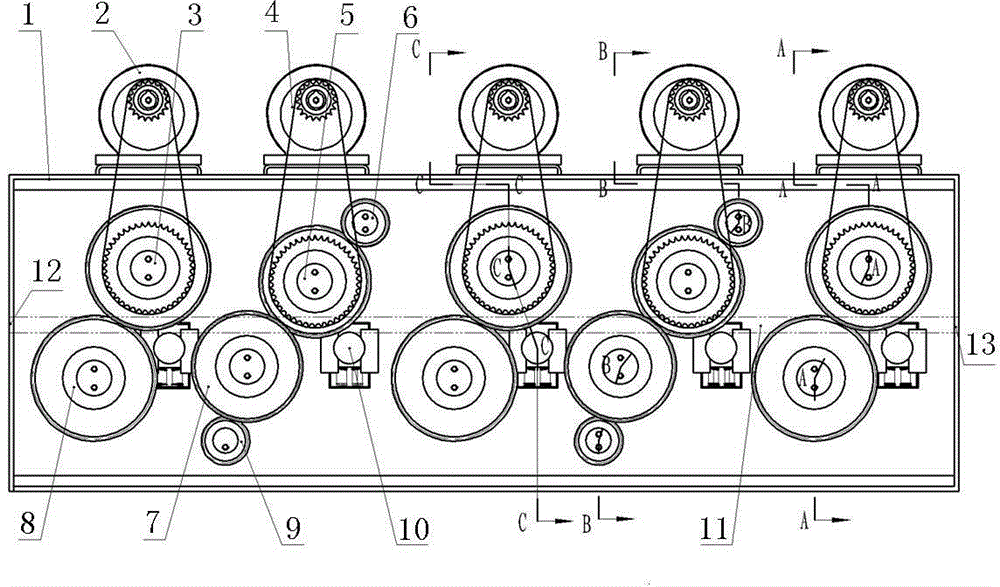

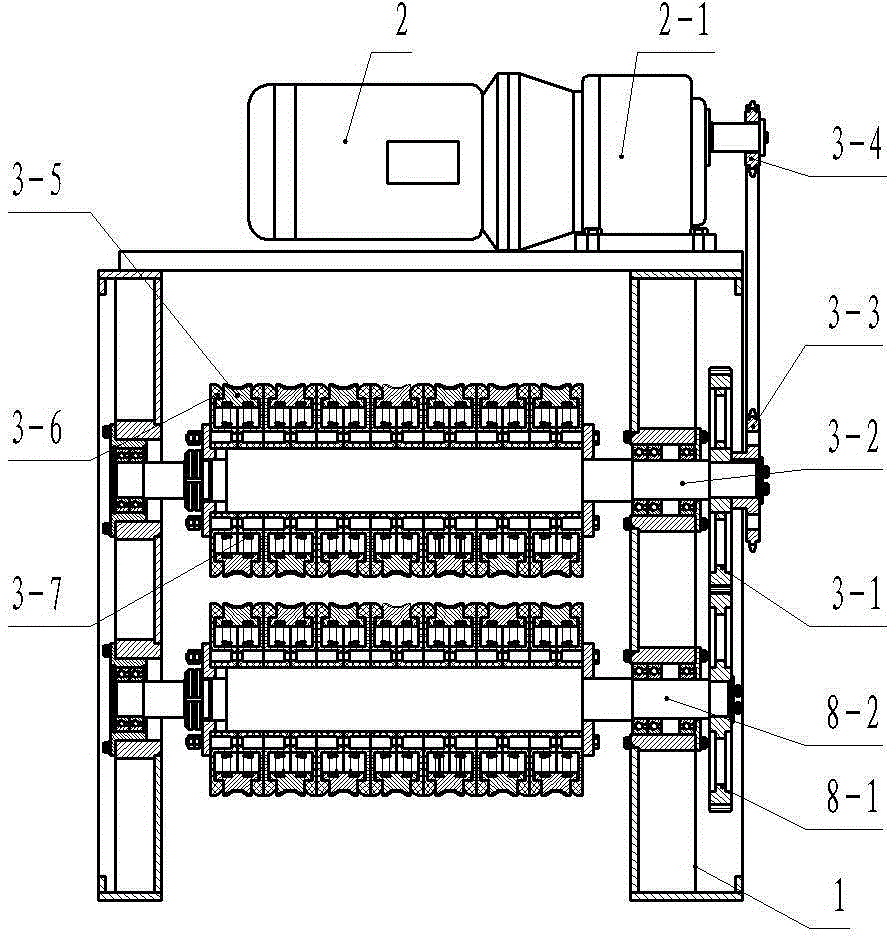

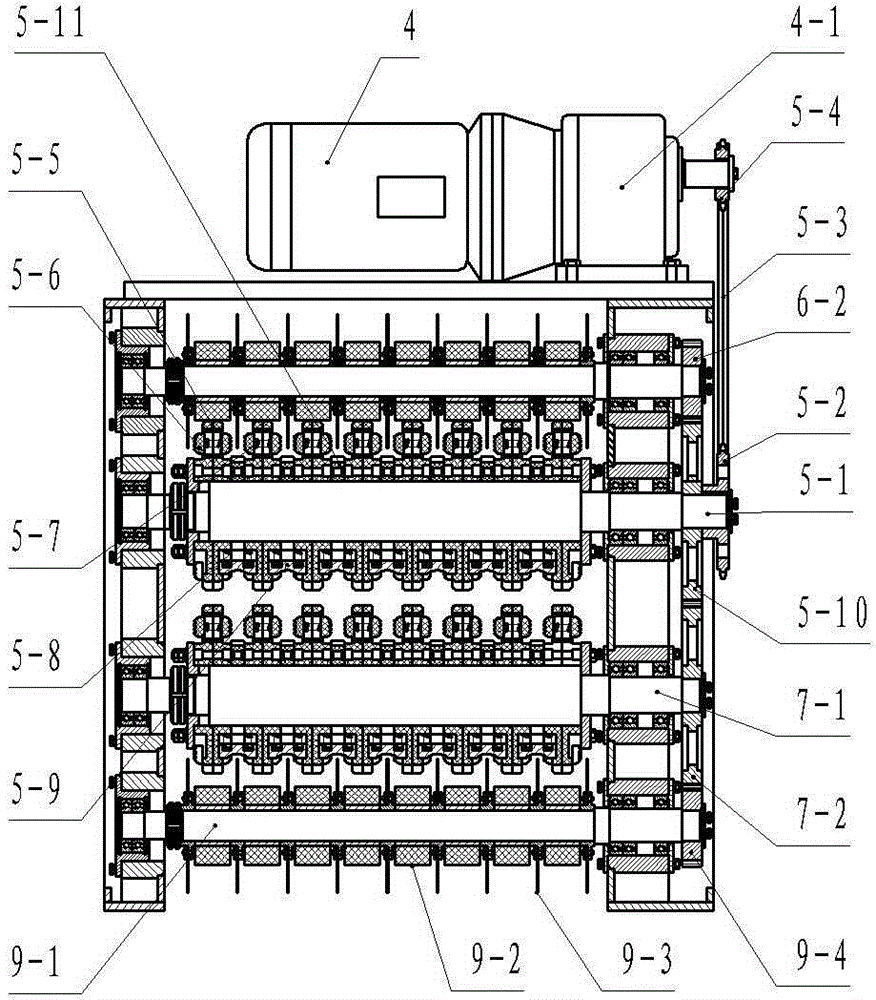

[0026] like figure 1 , figure 2 , image 3 and Figure 4 A sugarcane leaf stripping device shown includes a separation chamber 1 installed on both sides of the sugarcane harvester and three conveying roller devices and two leaf stripping rollers inserted in the sugarcane conveying channel in the two side plates of the separation chamber 1 Device, in this embodiment, between the cane inlet port 12 and the cane outlet port 13 on the sugarcane conveying passage 11, three conveying roller devices and two leaf stripping roller devices are alternately arranged in sequence; Cane rollers 10 are installed between the leaf roller devices, and the sugarcane rollers 10 include a roller shaft 10-1 and a roller 10-2 set on the roller shaft 10-1, and the roller shaft 10-1 is installed on the On the bearing seat, the bearing seat is respectively installed on the bearing seat mounting holes of the two side plates of the separation chamber 1, and the telescopic spring 10-3 is installed betw...

Embodiment 2

[0031] Each leaf-stripping tooth disk set 5-5 in this embodiment is provided with two radially outwardly extending teeth, and other features are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com