A detection system and method for the service life of a membrane module

A detection method and detection system technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of unsimulated end-face cycle impact force and low number of cycles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

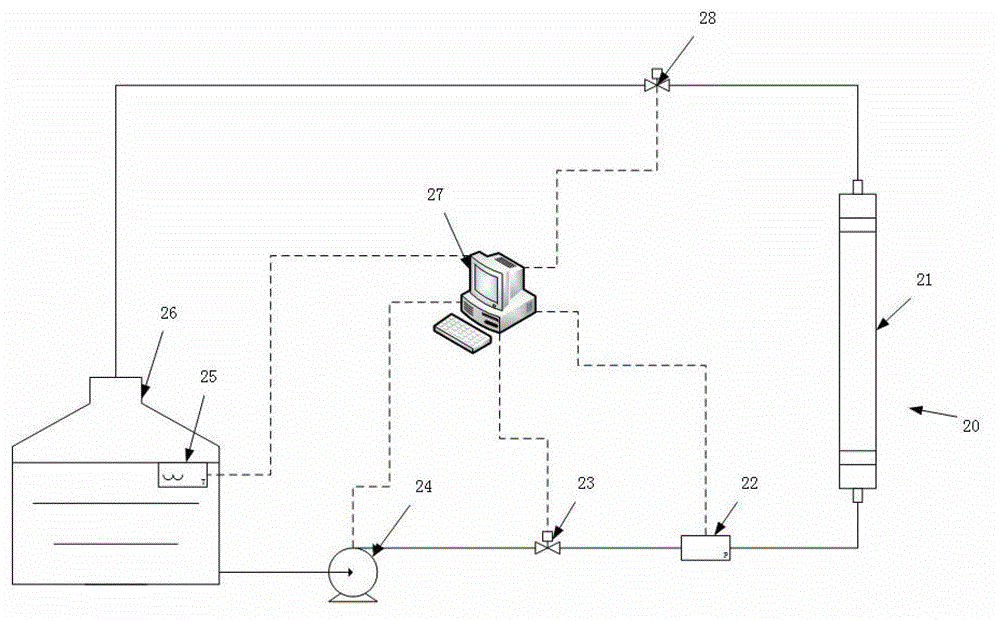

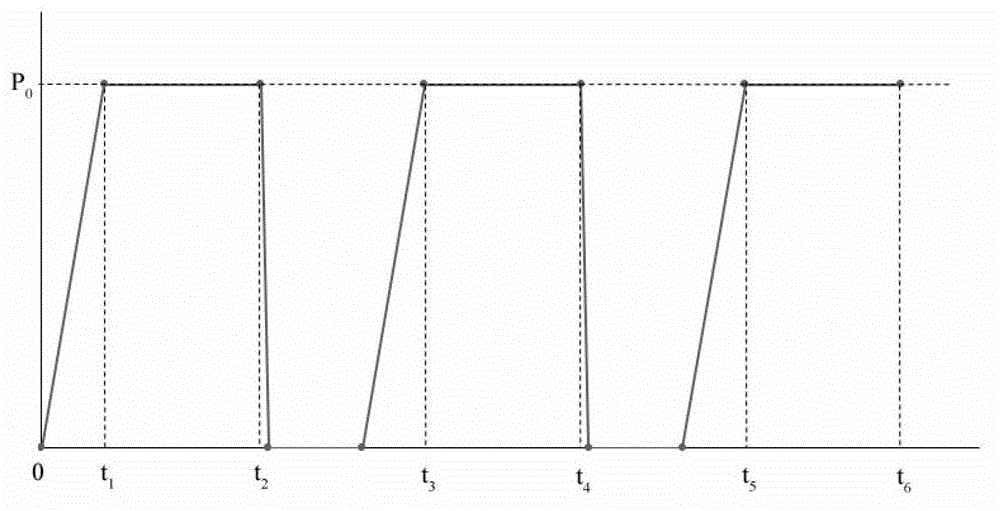

Embodiment 1

[0024] Connect the six-inch polyvinylidene fluoride column ultrafiltration membrane module 1 into the detection system, adjust the water temperature of the water inlet tank to 45°C through the heating unit, open the water inlet solenoid valve through the control unit, close the water outlet solenoid valve, and start the water inlet. The water pump pumps water from the water inlet of the membrane module, adjusts the water inflow so that the impact pressure in the module quickly reaches 0.3MPa, and keeps the pressure for 10s; then through the control unit, the water outlet solenoid valve is opened, the water inlet solenoid valve is closed, and the water is discharged quickly. The pressure reaches zero, and the pressure is released for 5 seconds; through the control unit, the pressure holding operation and the pressure relief operation cycle are carried out alternately, the membrane module maintains a cycle of 100,000 times, and the end surface of the membrane module package is not...

Embodiment 2

[0026] Same as Example 1, the inlet water temperature is 25°C, the impact pressure is 0.5MPa, the pressure holding time is 30s, the pressure release time is 15s, the module maintains 100,000 cycle pulses, and the end surface of the membrane module package is not cracked or damaged.

Embodiment 3

[0028] Same as Example 1, the inlet water temperature is 5°C, the impact pressure is 0.4MPa, the pressure holding time is 20s, the pressure release time is 10s, the module maintains the cycle pulse 100,000 times, and the end surface of the membrane module package is not cracked or damaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com