Color wiping mechanism

A color wiping machine and color head technology, applied in the field of bamboo or wood color wiping devices, can solve the problems of low production efficiency, difficult to control the shade of color, unable to ensure the consistency of product surface effect, etc., and achieve uniform coloring and good effect. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

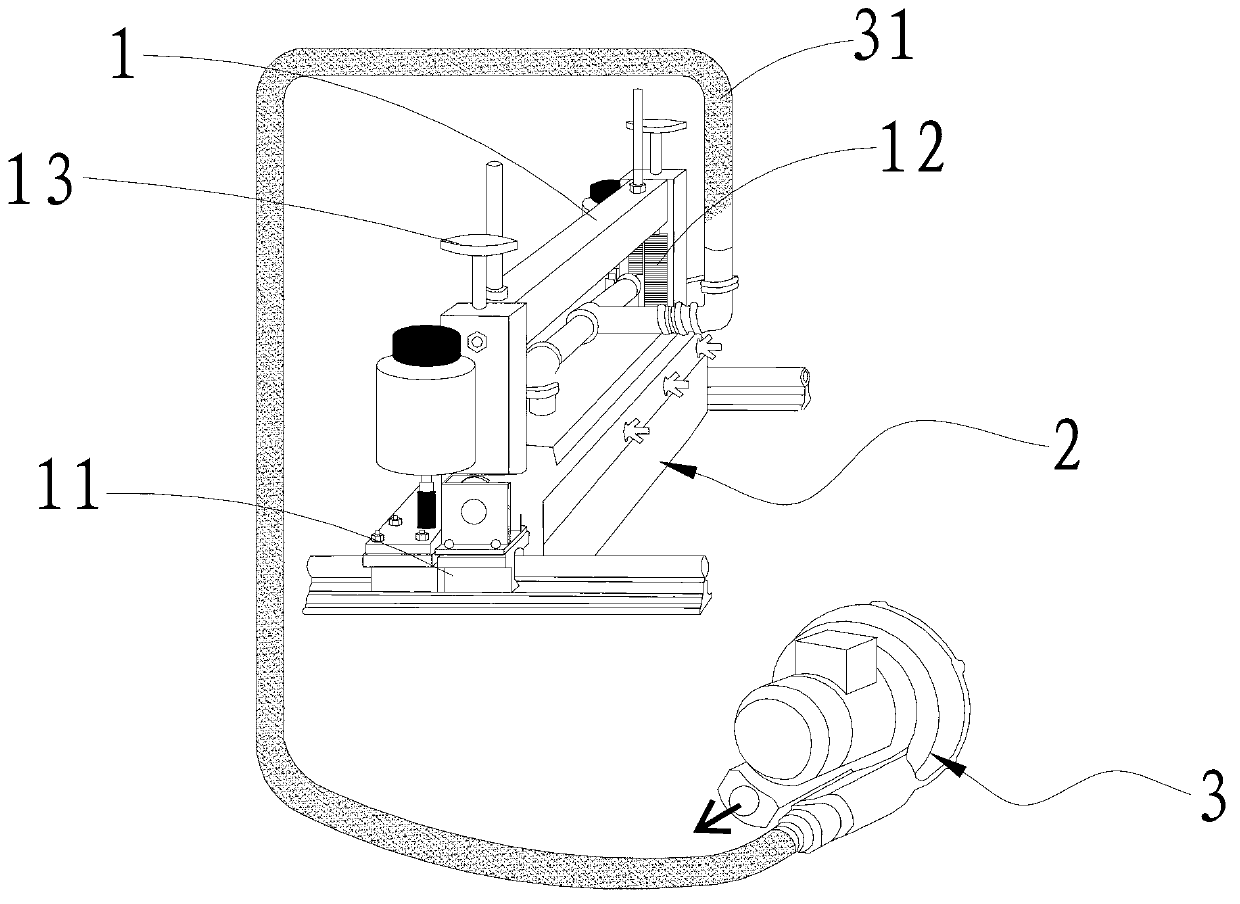

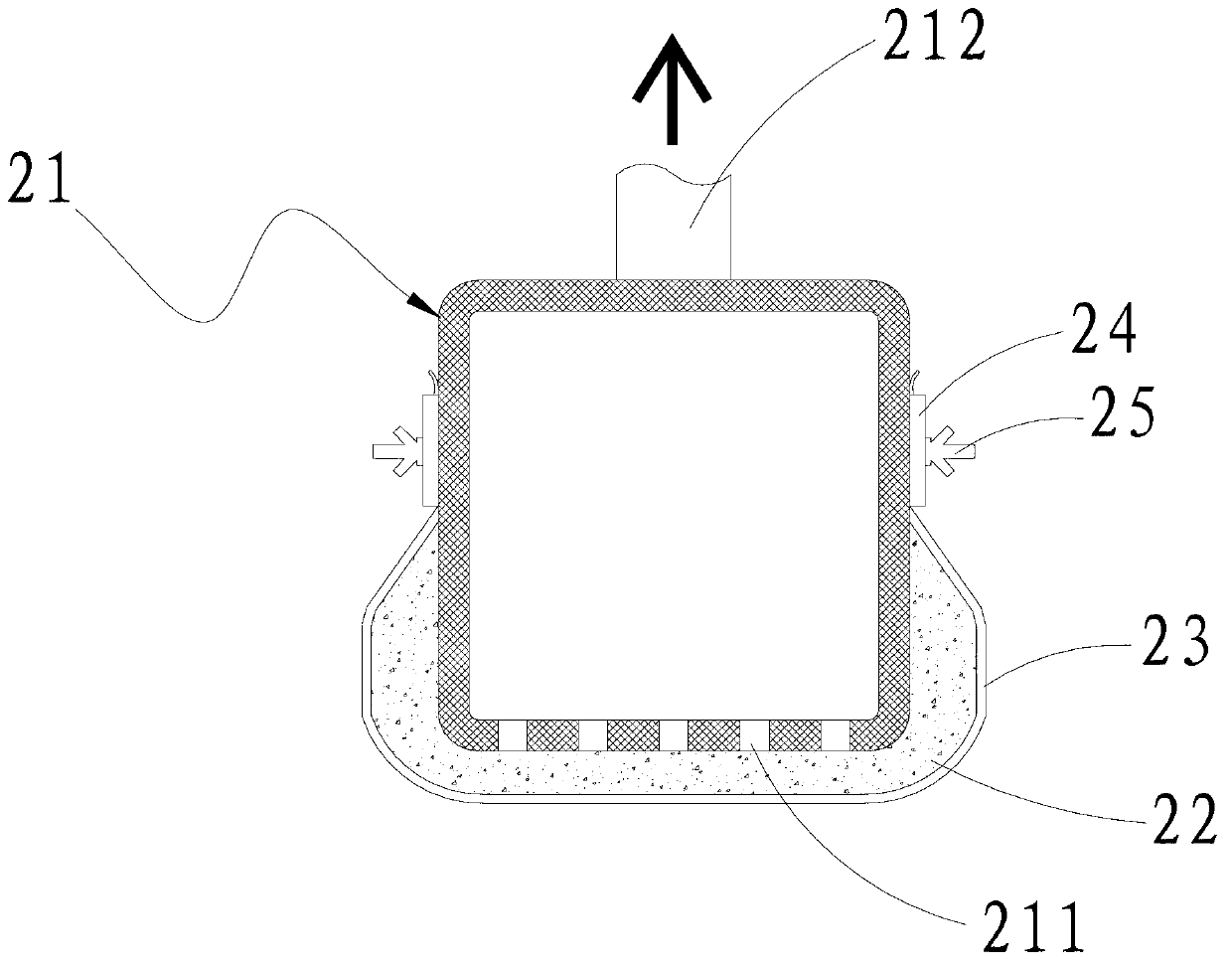

[0059] Please also refer to figure 1 , the color wiping mechanism of the present invention can be applied to general color wiping machines, and can also be applied to the assembly line of bamboo boards or even wood color wiping. The two ends of the shaped bracket 1 are respectively provided with sliders 11, through which the color wiping mechanism can slide on the linear guide rail or assembly line of a general color wiping machine, and the color wiping head 2 is installed on the lower end of the arched bracket 1, That is, it is placed horizontally and horizontally with the bamboo board, and a pressure spring 12 and an adjusting screw 13 for adjusting the pressure spring 12 are provided at the junction of the color wiping head 2 and the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com