An automatic equipment for taking enlarged size liquid crystal substrate

A technology of automation equipment and liquid crystal substrates, which is applied in the direction of lighting and heating equipment, conveyor objects, furnaces, etc., can solve problems such as panel cracking, damage to liquid crystal substrates, bumps and vibrations, etc., to improve the level of automation, reduce fragments, and increase production capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

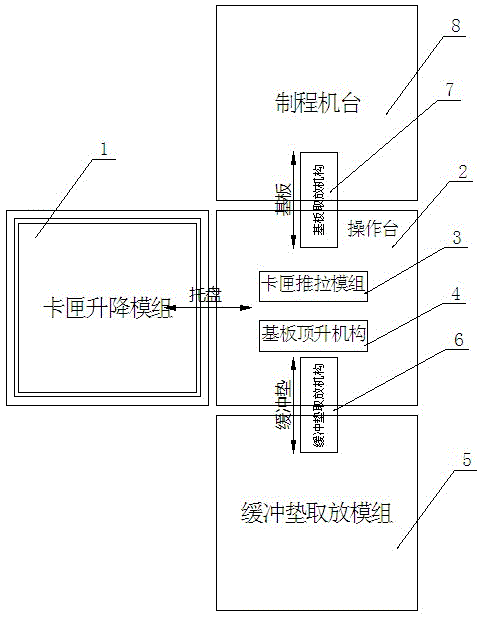

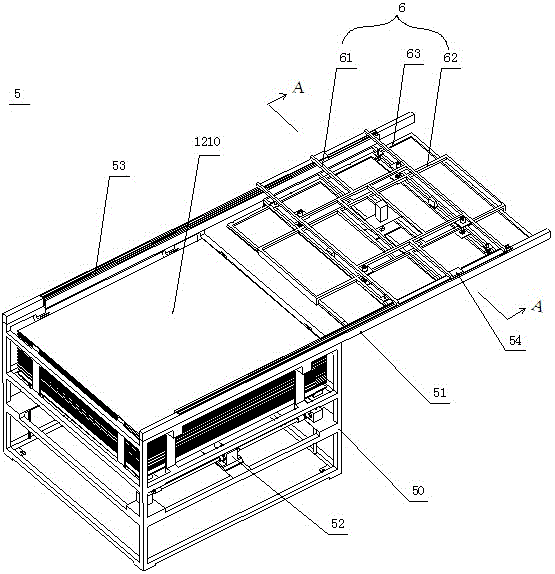

[0065] like figure 1 As shown, a schematic diagram of the working principle of an automatic equipment for taking an enlarged size liquid crystal panel substrate of the present invention is shown, from which it can be seen that the automatic equipment includes:

[0066] Cassette lifting module 1, which is provided with a cassette for stacking a plurality of trays inside, and the tray can slide out or slide into the cassette horizontally;

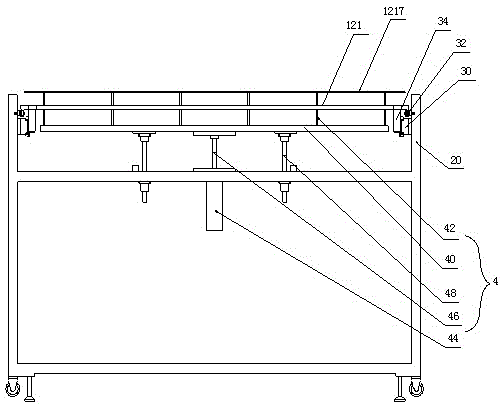

[0067] The operating platform 2 is facing the sliding direction of the tray of the cassette lifting module 1. The operating platform is provided with a cassette push-pull module 3, which is used to absorb a tray in the cassette and drive the tray to slide. in or out, so that the tray moves between the console and the cassette; in addition, a substrate lifting mechanism 4 is provided under the console, and the substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com