A kind of alcohol ether fuel and preparation method thereof

A fuel and alcohol ether technology, which is applied in the field of alcohol ether fuel and its preparation, can solve the problems of affecting product quality, rising vapor pressure, insufficient power, etc., and achieves the effects of good low-temperature start-up performance, improved engine power, and improved calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

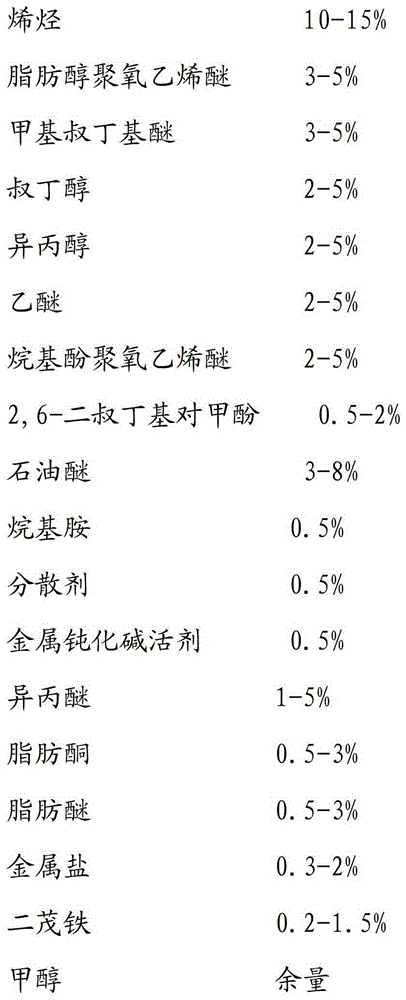

[0035] A preparation method of alcohol ether fuel, comprising: according to the following weight percentage, 10% olefin C 5 h 10 , 5% fatty alcohol polyoxyethylene ether C 12 h 25 O·(C 2 h 4 O) 15 , 4% methyl tert-butyl ether, 5% tert-butanol, 2% isopropanol, 3% ethyl ether, 5% nonylphenol polyoxyethylene ether (commercially available NP-10, degree of polymerization 10, HLB value 14) , 1% 2,6-di-tert-butyl-p-cresol, 8% petroleum ether (30°C-60°C), 0.5% hexadecylamine, 0.5% succinimide, 0.5% N,N-diethylene Salicylpropylenediamine, 5% isopropyl ether, 0.5% dimethyl ketone, 0.5% dibutyl ether, 2% lithium formate, and 1.5% ferrocene were placed in the reaction kettle in turn, and after circulating at room temperature for 5 hours at 40°C, Then add 46% methanol, circulate for 3 hours, settle for 12 hours, and put it into a tank after synthesis to obtain the finished product.

Embodiment 2

[0037] A preparation method of alcohol ether fuel, comprising: according to the following weight percentage, 15% olefin C 6 h 12 , 3% fatty alcohol polyoxyethylene ether C 12 h 25 O·(C 2 h 4 O) 10 , 3% methyl tert-butyl ether, 2% tert-butanol, 5% isopropanol, 2% ethyl ether, 2% octylphenol polyoxyethylene ether (commercially available OP-10, degree of polymerization 10, HLB value 14) , 0.5% 2,6-di-tert-butyl-p-cresol, 3% petroleum ether (30°C-60°C), 0.5% octadecylamine, 0.5% dienyl succinimide, 0.5% N,N - Disalicylylpropylenediamine, 1% isopropyl ether, 3% ethyl acetone, 3% diisopropyl ether, 0.3% zinc formate, 0.2% ferrocene were placed in the reaction kettle in sequence, and circulated at room temperature for 3 hours at 20°C Finally, add 55.5% methanol, circulate for 2 hours, settle for 12 hours, and put it into a tank after synthesis to obtain the finished product.

Embodiment 3

[0039] A kind of preparation method of alcohol ether fuel, comprising: according to following weight percentage, with 13% olefin C 7 h 14 , 4% fatty alcohol polyoxyethylene ether C 12 h 25 O·(C 2 h 4 O) 15 , 5% methyl tert-butyl ether, 4% tert-butanol, 4% isopropanol, 5% ethyl ether, 3% octylphenol polyoxyethylene ether (commercially available OP-10, degree of polymerization 10, HLB value 14) , 2% 2,6-di-tert-butyl-p-cresol, 5% petroleum ether (30°C-60°C), 0.5% triethylamine, 0.5% succinimide, 0.5% N,N-dihydrate Yang Prodiamine, 3% isopropyl ether, 2% methyl ethyl ketone, 2% diisopropyl ether, 1% magnesium acetate, 1% ferrocene were placed in the reaction kettle in turn, and after circulating at room temperature for 4 hours at 30°C, then added 44.5% methanol, circulated for 3 hours, precipitated and placed for 12 hours, synthesized and packed into a tank to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com