Methanol engine low-temperature cold start method

A methanol engine, cold start technology, applied in engine components, combustion engines, machines/engines, etc., can solve problems such as difficulty in cold start of methanol engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

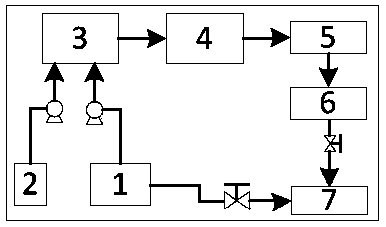

[0015] According to the low-temperature cold-start method of the methanol engine in the specific embodiment of the present invention, when the engine is cold-started at low temperature, the mode of on-line methanol hydrogen production reformed gas (mainly composed of H2 and CO2) is adopted, and the reformed gas is mixed with air and then enters the cylinder Ignition, after the engine starts successfully, the temperature of the cylinder wall surface and the cylinder head wall surface is already high at this time, and the mixture of methanol and air is easier to ignite, so as to solve the problem of difficult cold start of the methanol engine in the methanol combustion mode at low temperature.

[0016] Such as figure 1 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com