Cylindrical yarn dyed jacquard filling-wise elastic towel fabric and weaving method thereof

A cylindrical and fabric technology, applied in fabrics, textiles, papermaking, textiles, etc., can solve the problems of large water consumption, high energy consumption, low color fastness, etc., achieve high weft elasticity, improve production efficiency, simplify The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

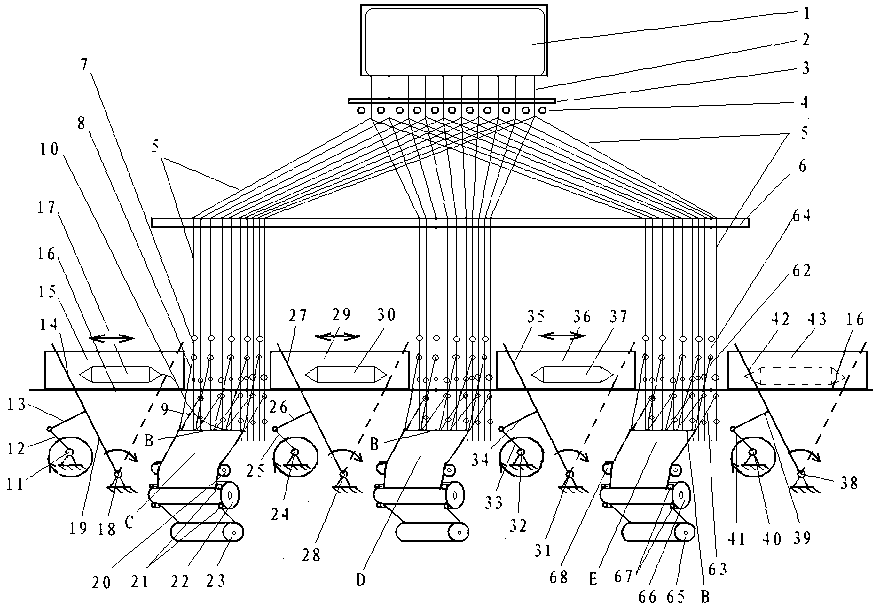

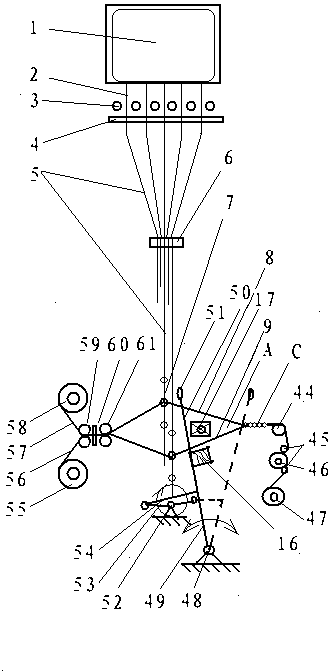

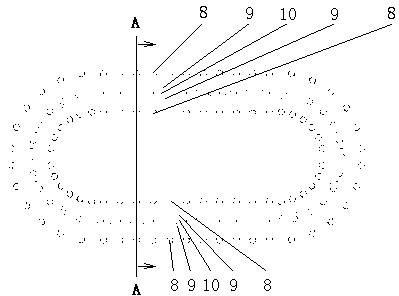

[0031] The cylindrical yarn-dyed jacquard weft-elastic towel fabric of the present invention needs to be woven on a shuttle loom modified by weft insertion and beating-up devices. Modified looms such as figure 1 , 2 As shown, it consists of shedding mechanism and heald lifting system (jacquard machine faucet 1, harness 5, eye board 6 and heddle 7), multi-width weft insertion mechanism (shuttle box 15, shuttle 17, picker bar 14, picker side Shaft 11, picking cam 12, picking rod connecting rod 13, shuttle box 15, opposite side shuttle box 29, etc.), synchronous beating-up mechanism (steel reed 50, sley wood 16, reed foot shaft 48, sley foot 49 , bent shaft 52, bent shaft crank 53, sley foot beat-up link 54, reed cap 51), fabric take-up mechanism (chest beam 44, fabric guide roller 45, take-up roller 46 and cloth take-up roller 47) and double Warp beam let-off mechanism (ground warp beam 55, pile warp beam 58, double back rest 59, warp stopper 60, twisting rod 61), tension cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap