Antiskid and anti-seepage fog sealing layer technology

A fog sealing layer and anti-seepage technology, which is applied in the direction of building components, pavement details, building insulation materials, etc., can solve the problems of shedding, inability to prevent slipping, inability to prevent water seepage, etc., and achieve enhanced adhesion, Effect of increasing penetration and improving slip resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

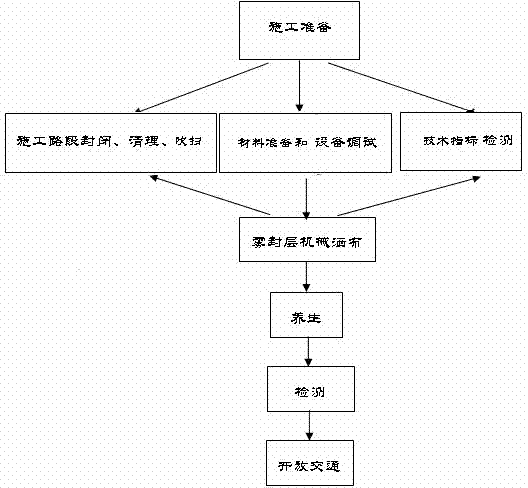

[0027] Such as figure 1 As shown, the anti-skid and anti-seepage fog sealing process, it specifically includes the following steps:

[0028] step 1:

[0029] 1) The construction section is closed, cleaned, and blown. In order to ensure the construction quality of the fog seal layer, the construction of the fog seal layer must ensure that the road surface is clean, and the loose stones, dirt, dust, and debris on the original road surface must be thoroughly cleaned. It can be washed with a road sweeper or water, but it must be noted that the water washing must be completed 24 hours before, and the road surface must be dry during construction.

[0030] 2) Material preparation and equipment debugging;

[0031] The materials are prepared as follows:

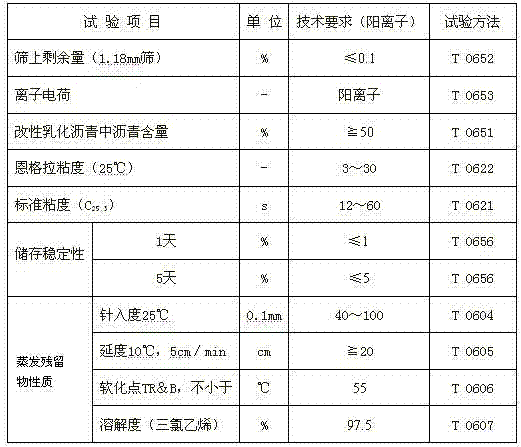

[0032] a) Selected material: base asphalt: 70 # or 90 # Grade A road petroleum asphalt (here is 90 # Grade A road petroleum asphalt); emulsifier: cationic emulsifier; modifier: latex; anti-reflection agent: alcohol anti-reflect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com