Stability strengthening structure of continuously welded rail on bridge

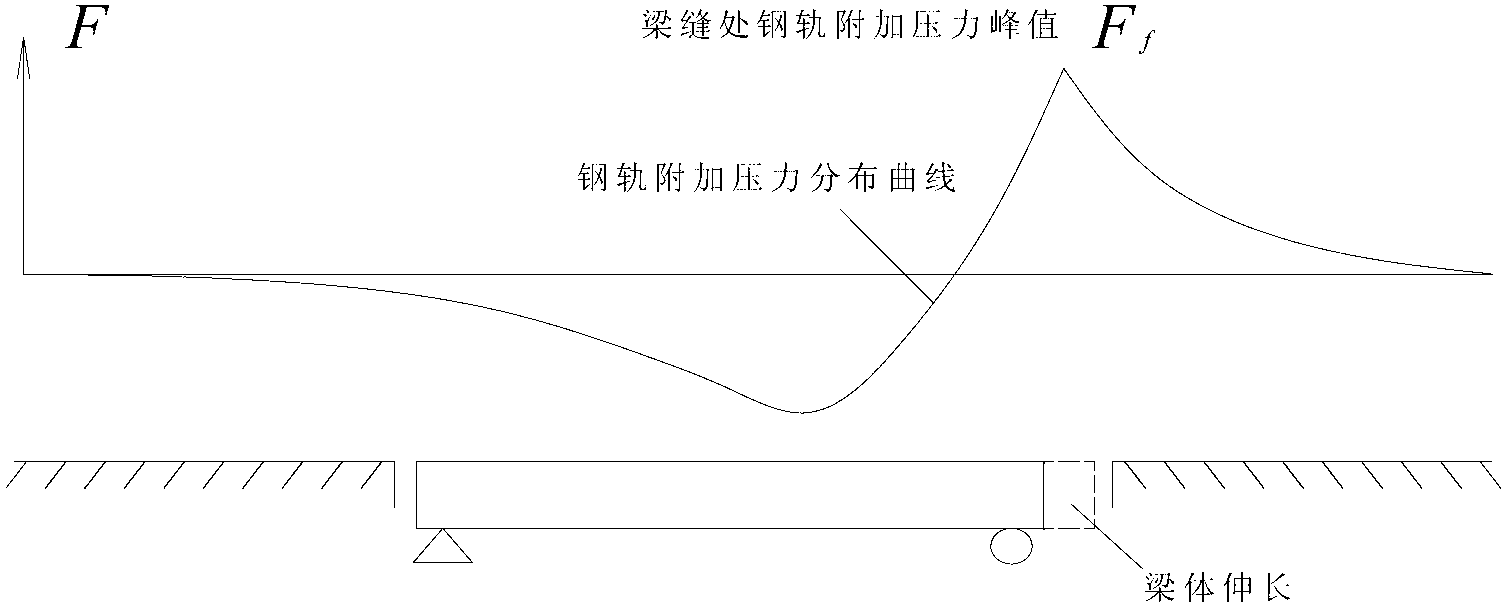

A seamless track and stable technology, applied to roads, bridges, bridge parts, etc., can solve problems such as inconvenient installation and disassembly, disturbance of ballast bed, affecting maintenance and repair operations, etc., to achieve convenient installation and disassembly, improve track frame rigidity, and install Simple, fast and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

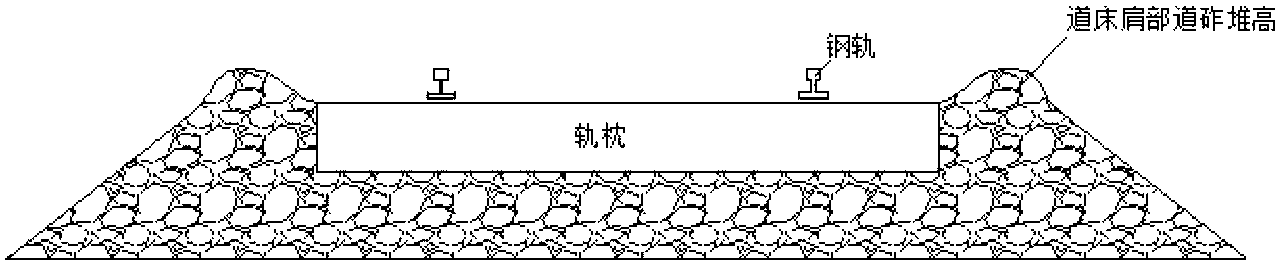

Method used

Image

Examples

Embodiment Construction

[0019] The structure of the present invention will be described in further detail below in conjunction with the accompanying drawings.

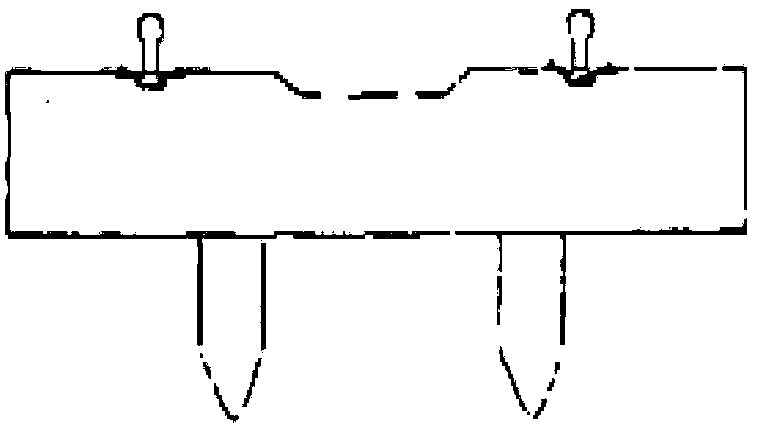

[0020] combine Figure 5 to Figure 7 can be seen. 1 is the main line rail, 2 is the sleeper, and 3 is the guard rail. A number of crimping fixture units are arranged between the rail bottoms of the two guard rails between the sleepers. The pinch plate 5 and the rigid connecting rod 8 connected by the bottom plate. A crimping fixture is installed at the bottom of the guard rail between the sleepers, and the crimping fixture is composed of three parts: a base plate 4, a buckle plate 5, and a coupling mechanism. Depend on Figure 7 It can be seen that firstly the base plate 4 and the pinch plate 5 are combined and buckled on the bottom of the guard rail, and then the nut 7 is tightened after the stud bolt 6 passes through the reserved middle hole of the base plate 4 and the pinch plate 5 from the bottom. The gusset plate is provided with two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com