Control device and control method thereof for oil-gas well multistage perforator

A control device and perforator technology, applied in earthwork drilling, wellbore/well components, mining fluids, etc., can solve problems such as potential safety hazards, lack of fault detection functions, spurious ignition current and misinitiation of detonators, etc., to achieve Low cost, easy to implement, and high reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

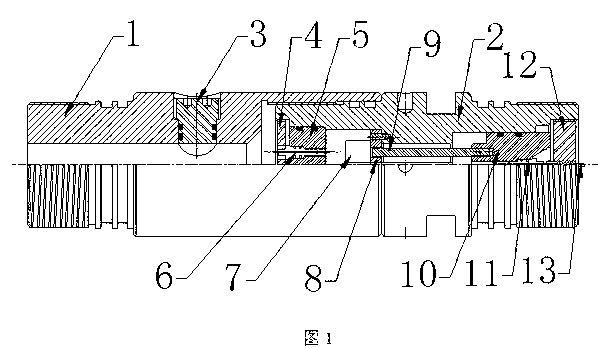

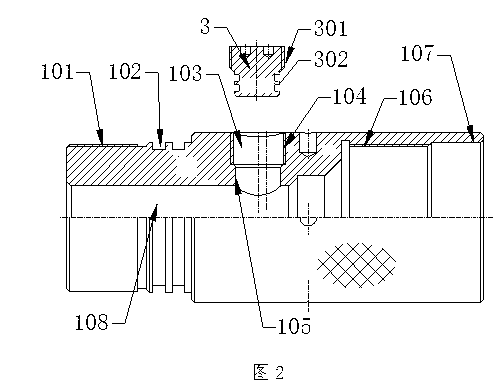

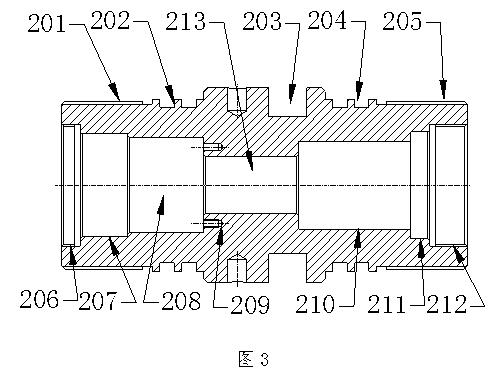

[0041] First install two sealing rings and four shear pins on the actuating piston 10, install the lower wiring pin 11 and the on-off insertion rod 9 at the corresponding positions of the actuating piston, and then turn the on-off insertion rod 9 to the left to move the actuating piston 10 from the The right end of the sub-joint 2 of the graded perforation is inserted, and the shear pin just falls on the step between 211 and 210; the control circuit board 7 is fixed on the middle fixed plate 8, and the control circuit board 7 faces left from the graded shot. Insert the left end of the joint 2 under the hole, and land on the step between 208 and 213. The upper two fixing screws are fixed on 209, and let the upper end of the lower connection pin 11 and the left end of the on-off insertion rod 9 fix the corresponding channel of the plate 8 from the middle. Stretch out, the lower wiring pin 11 is connected to the lower connection pin of the control circuit board 7, the on-off inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com