Buoyancy valve, washing system and engineering machine

A technology of buoyancy valves and buoyancy chambers, which is applied to mechanical equipment, valve details, multi-way valves, etc., can solve the problems of not being able to determine whether there is still water in the washing pipeline, and the effect of emptying cannot be guaranteed, so as to reduce rust Or the probability of being damaged by freezing, the effect of improving the service life and user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other under the condition of no conflict. The following will be combined with the Figures 1 to 6 Specific embodiments of the present invention will be described in detail.

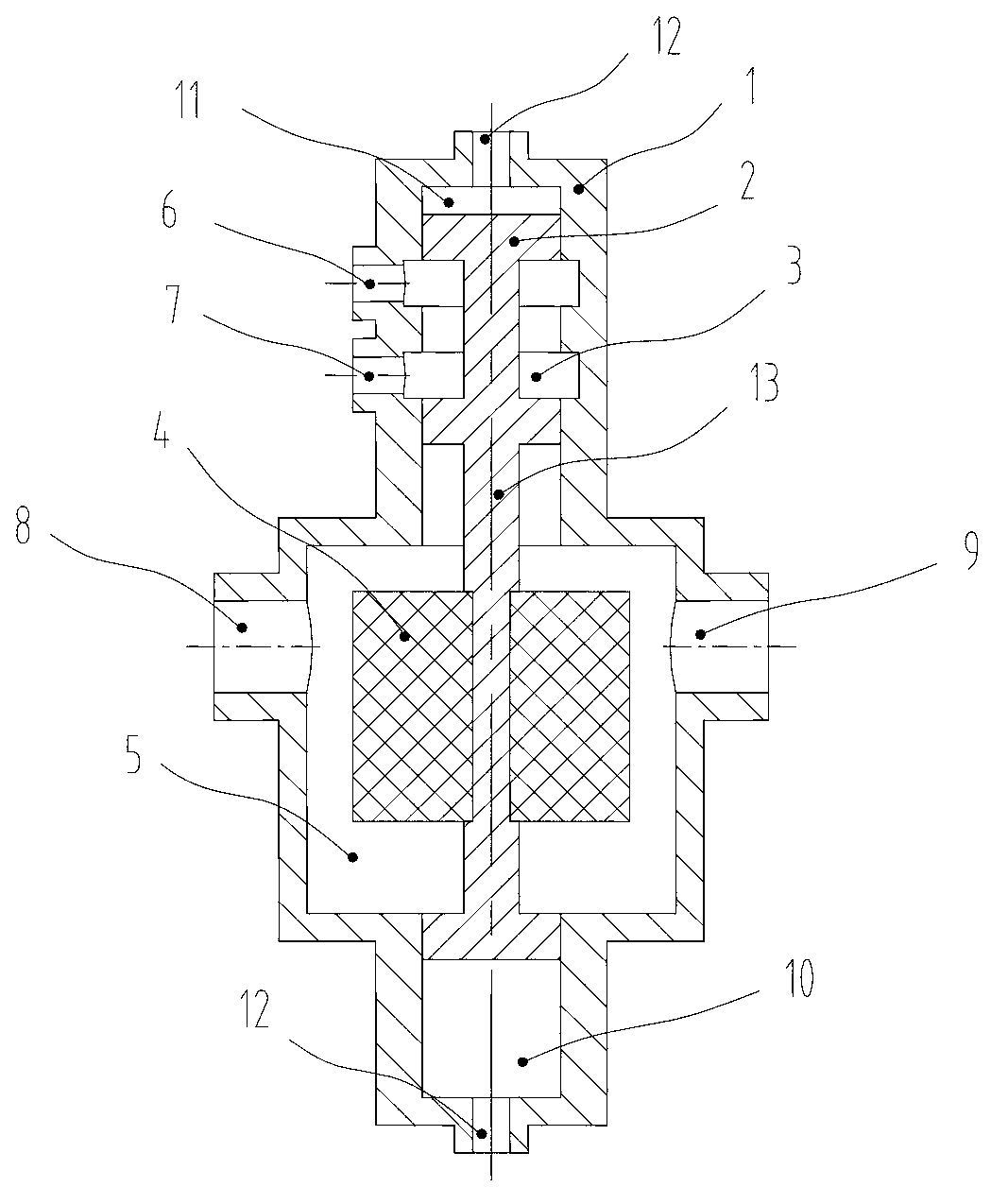

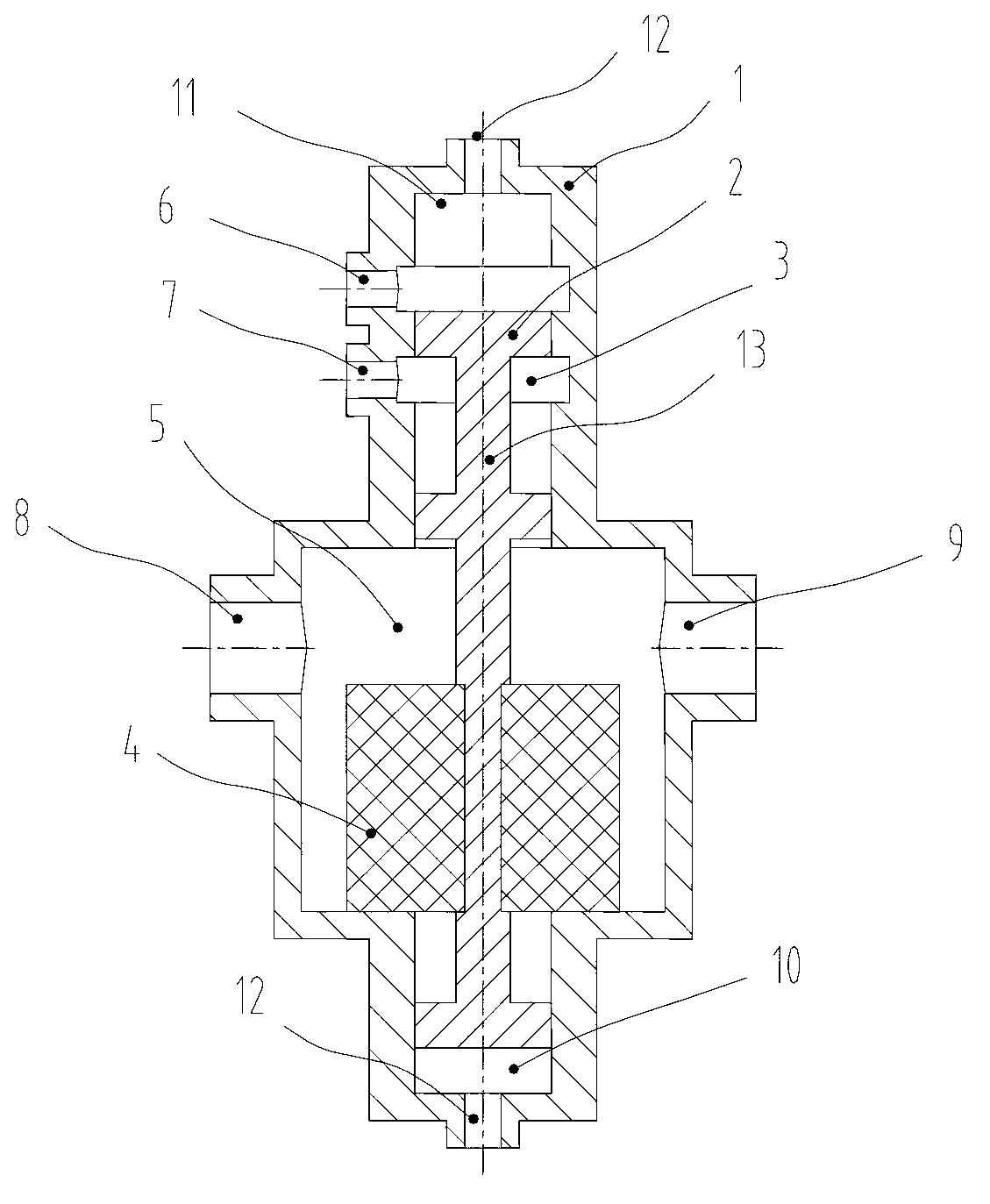

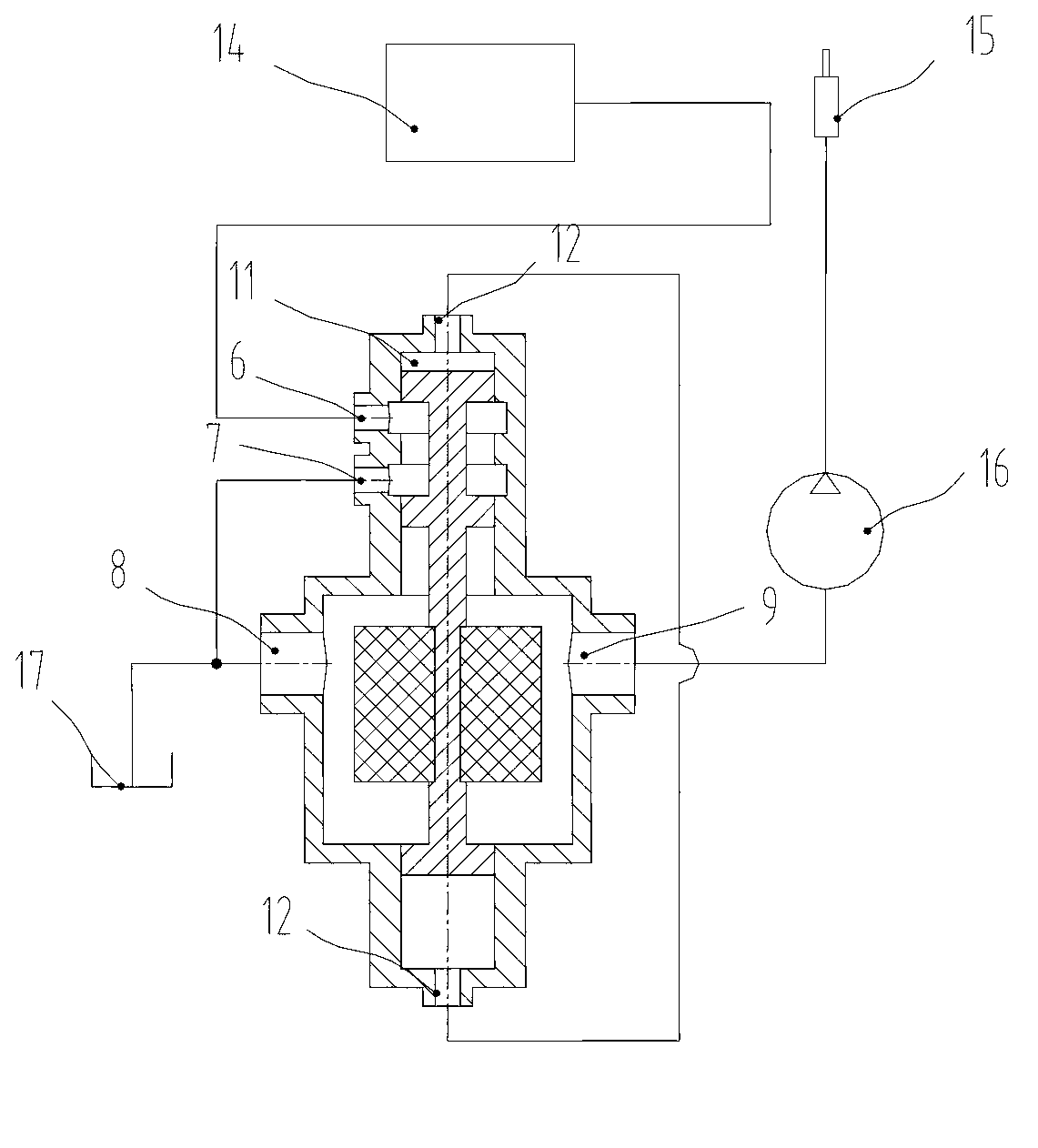

[0025] figure 1 A schematic structural diagram of a buoyancy valve in a floating state proposed by a specific embodiment of the present invention; figure 2 for figure 1 The structure diagram of the shown buoyancy valve in the initial state; image 3 A schematic structural diagram of a water washing system proposed by a specific embodiment of the present invention; Figure 4 A schematic structural diagram of another water washing system during water washing proposed by a specific embodiment of the present invention; Figure 5 for Figure 4 Schematic diagram of the structure of the shown washing system when it is draining; Image 6 for Figure 4 Schematic diagram of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com