Clamping device for plant leaf surface physical parameter detection sensor

A technology for detecting sensors and physical parameters, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems that affect the measurement accuracy of measuring instruments, the front end is prone to opening, and the sensor is unreliable, so as to reduce damage to the measured object, Optimize the overall structure and the effect of reliable fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

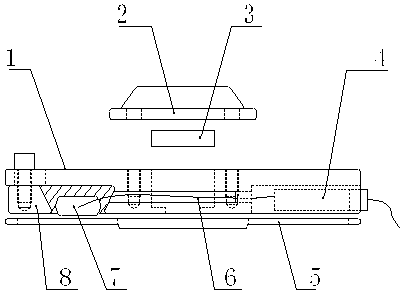

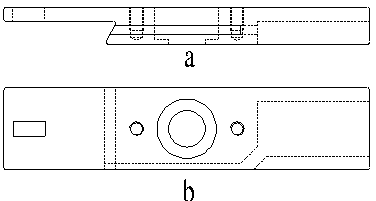

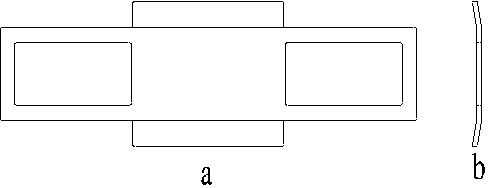

[0016] Such as figure 1 As shown, the present invention includes a splint one 1, a magnet cover plate 2, a magnet 3, a USB connector 4, a splint two 5, a wiring groove 6 and a trapezoidal pressing block 8; a stepped through hole is opened in the center of the splint one to place the magnet, Adjust the depth of the magnet according to the thickness of the added blade to achieve a suitable clamping force, and then seal it with a magnet cover and screws. In addition, there are protruding parts on both sides of the magnet cover, so that you can hold the first splint; the ladder of the first splint The peripheral side of the hole is in the shape of a half dovetail groove, and there is a rectangular groove on the splint corresponding to the end of the dovetail groove. The trapezoidal pressing block can freely adjust the position in the rectangular groove through screws, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com