Annular cutting device

A kind of annular shearing and annular technology, which is used in measuring devices, using a stable shear force to test the strength of materials, instruments, etc. The problem of high maintenance cost, to achieve the effect of easy inspection and maintenance, low maintenance cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

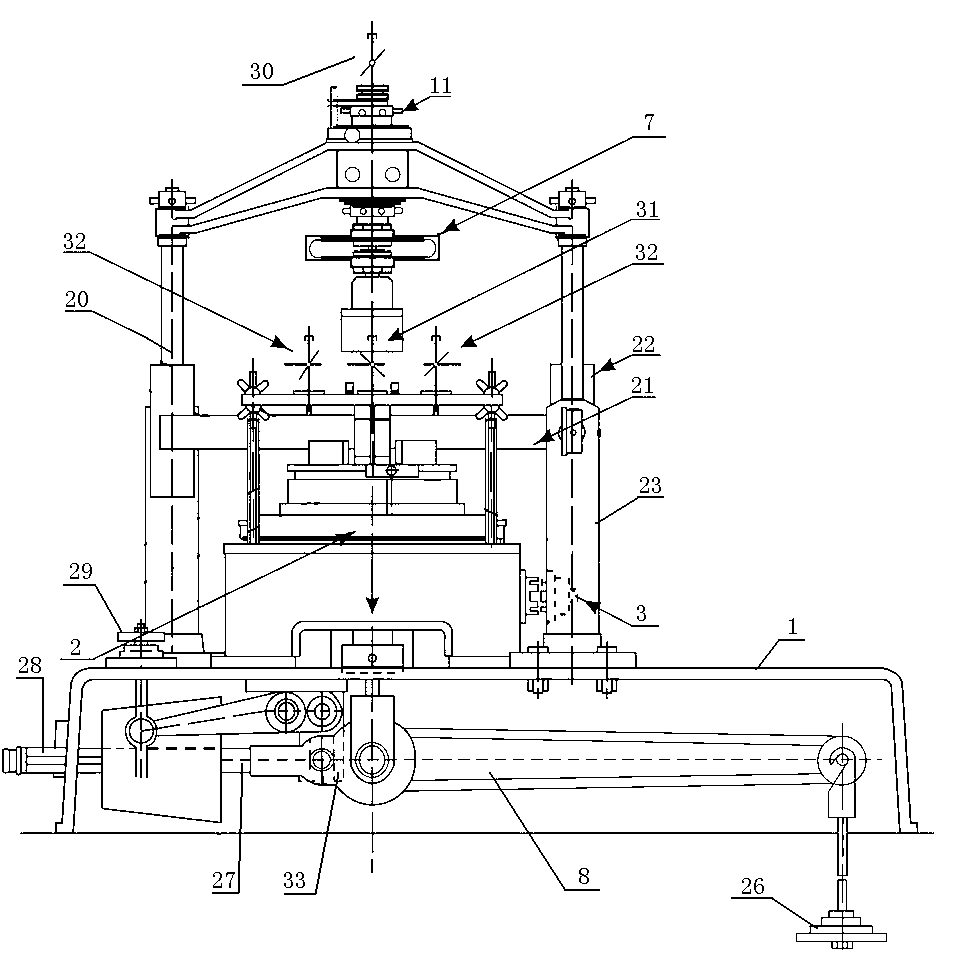

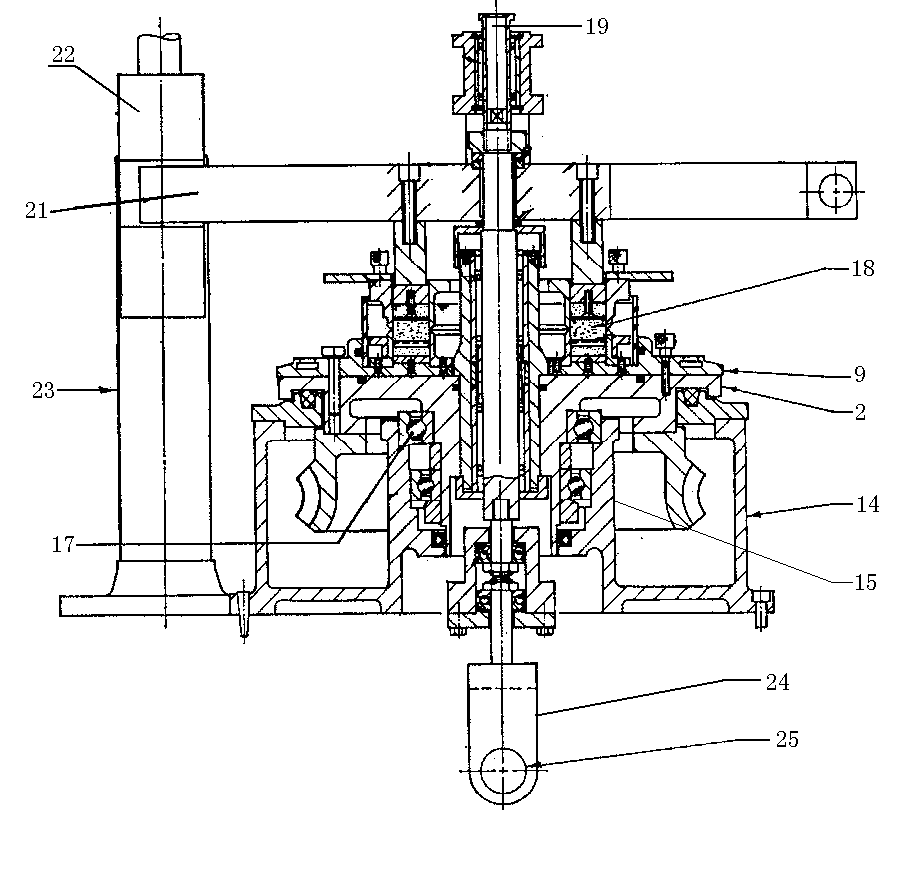

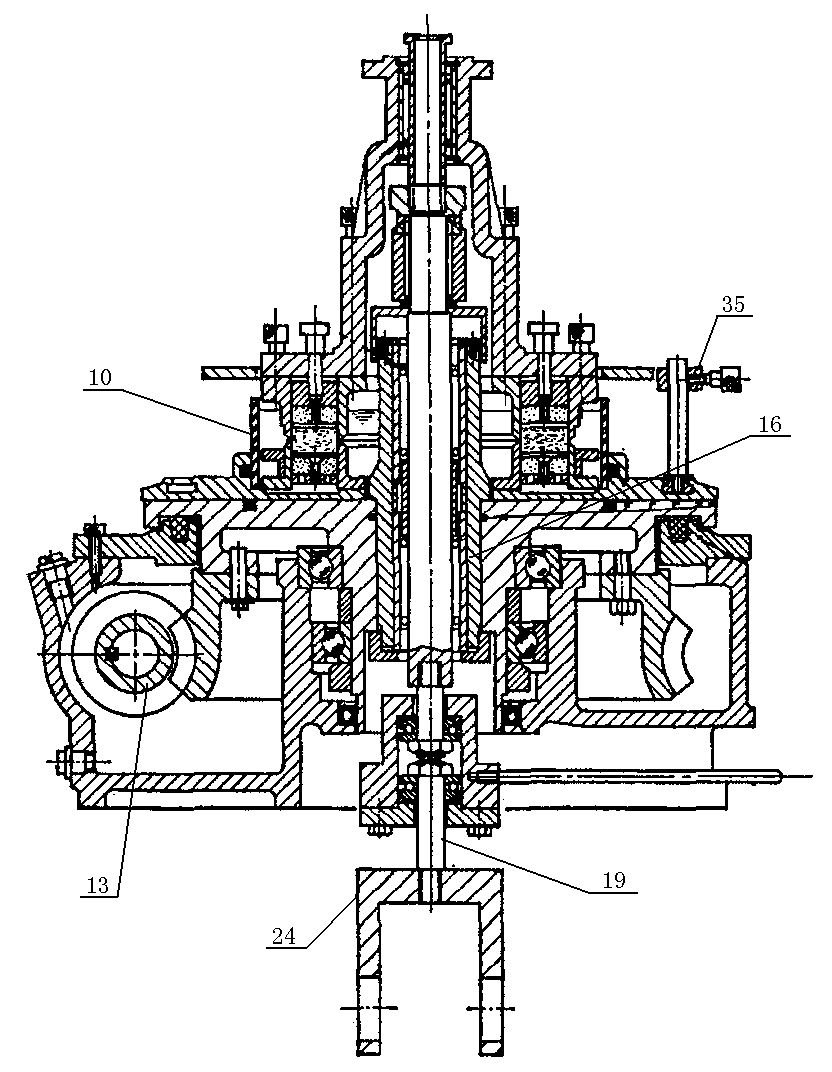

[0022] Below in conjunction with accompanying drawing, the present invention will be further described:

[0023] combine figure 1 , Figure 4 As shown, this annular shearing device includes a base 1, a rotary table 2, a rotary drive mechanism 3, an upper fixed ring 4, a lower fixed ring 5, a vertical loading mechanism, an annular loading plate 6, a force measuring ring 7, a tangential The load measuring ring 22, the rotating platform 2 is installed on the base 1, the rotating drive mechanism 3 is connected to the rotating platform 2, the annular chassis 9 is installed on the rotating platform 2, the plexiglass water tank 10 and the annular chassis 9 are fixedly connected as one, The lower fixing ring 5 is arranged at the bottom of the organic glass tank 10, and the bottom of the lower fixing ring 5 has a porous ceramic ring 12; the upper fixing ring 4 is arranged on the lower fixing ring 5 through a vertical loading mechanism, and the upper fixing ring 4 and the lower fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com