electroscanner

A scanner and rotation center technology, applied in the field of electric scanners, can solve problems such as large moment of inertia and poor response characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

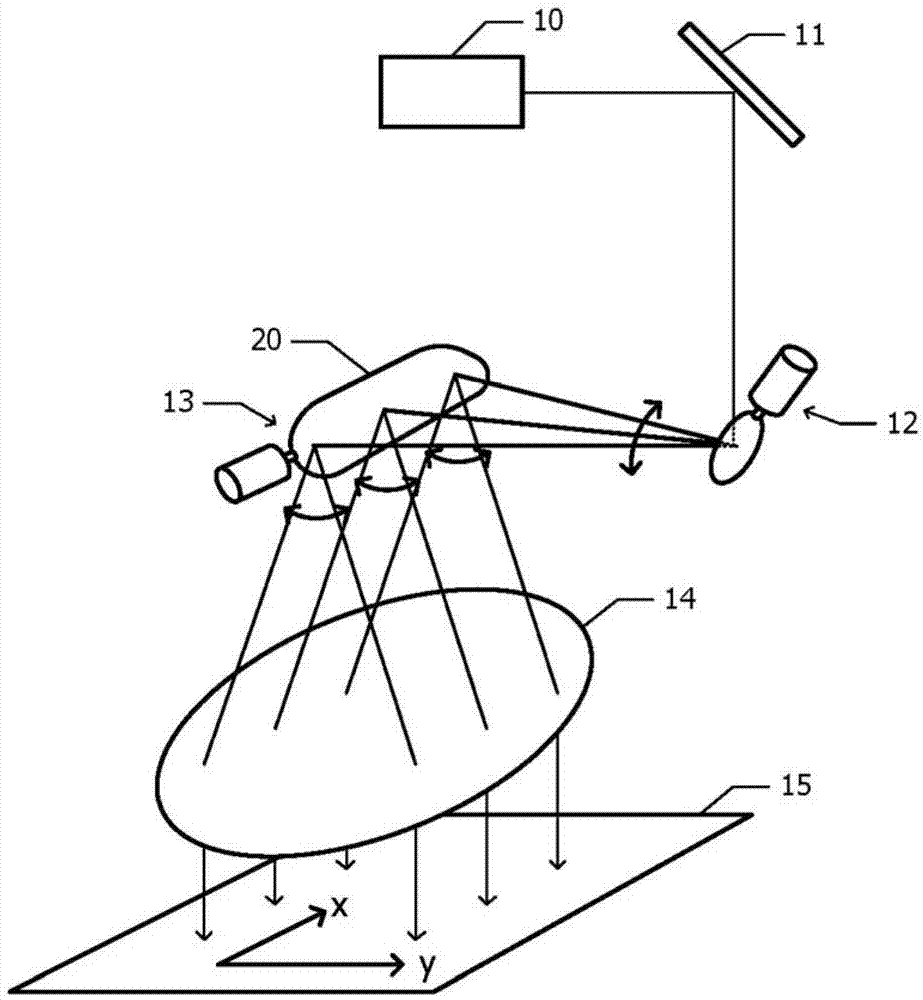

[0026] figure 1 A schematic diagram of laser drilling using the galvano scanner of Example 1 is shown in . The laser beam emitted from the laser light source 10 enters the object 15 through the deflection mirror 11 , the first-stage galvano scanner 12 , the second-stage galvano scanner 13 , and the fθ lens 14 . In addition, beam expanders, masks, lenses, etc. are arranged as necessary. An xy Cartesian coordinate system in which the surface of the object 15 to be processed is defined as an xy plane is defined.

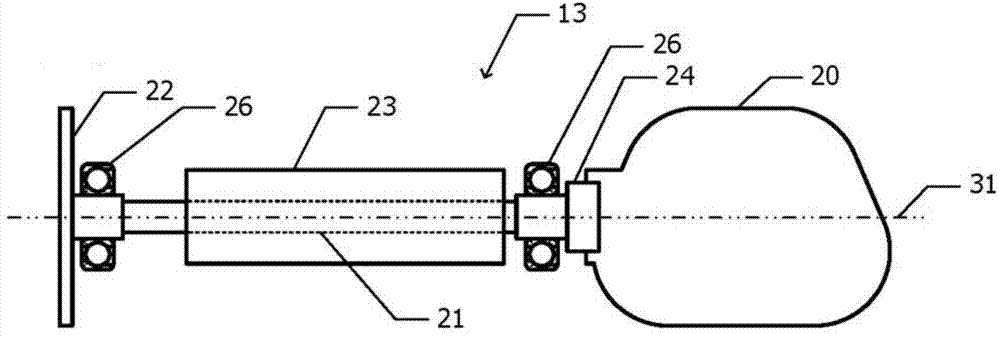

[0027] The first-stage galvano scanner 12 moves the incident point of the laser beam in the x direction on the surface of the object 15 to be processed. When the advancing direction of the laser beam is swung by the first-stage galvano scanner 12 , the incident point of the rotating mirror 20 toward the second-stage galvano scanner 13 moves in the x direction. The second-stage galvano scanner 13 moves the incident point of the laser beam in the y direction on the sur...

Embodiment 2

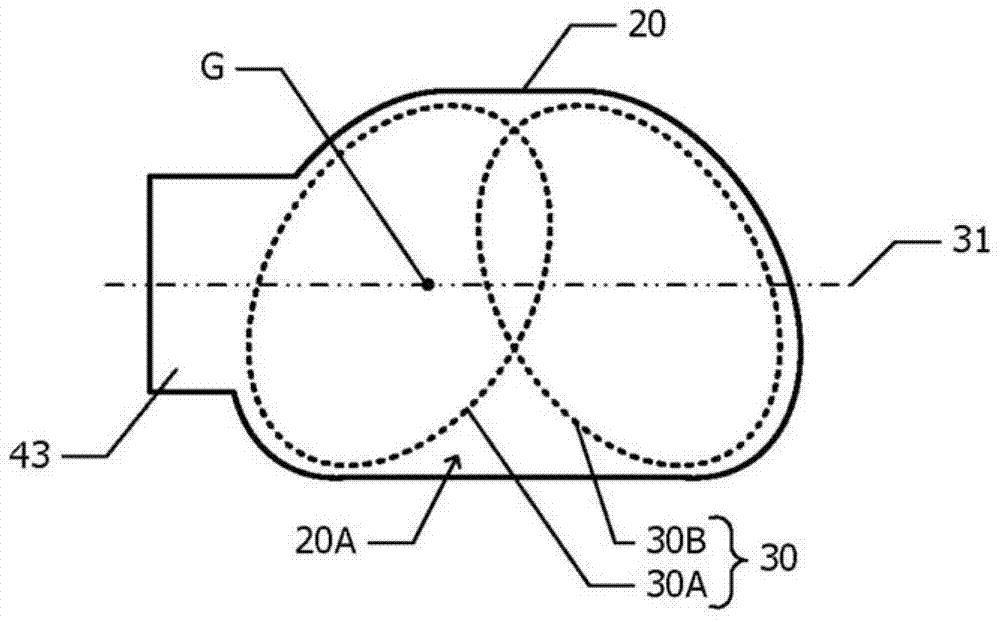

[0050] Figure 7A and Figure 7B A front view and a rear view of the rotating mirror of the galvano scanner according to the second embodiment are respectively shown in . Hereinafter, differences from the galvano scanner according to the first embodiment described above will be described, and the description of the same configuration will be omitted.

[0051] like Figure 7A As shown, the reflective surface 20A of the rotating mirror 20 of the electronic scanner according to the second embodiment is symmetrical with respect to the rotation center line 31 . like Figure 7B As shown, the first reinforcing rib 41 extends from the grip portion 43 along the rotation center line 31 and becomes thinner toward the tip, as in the case of the first embodiment. The second reinforcing rib 42 branches from the first reinforcing rib 41 as in the case of the first embodiment. Furthermore, the second reinforcing rib 42 extends from a direction perpendicular to the rotation center line 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com