AT89C51 single chip microcomputer infrared temperature measurement system

An AT89C51, infrared temperature measurement technology, applied in general control system, control/adjustment system, computer control, etc., can solve the problems that do not meet the requirements of ISO9000 quality system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

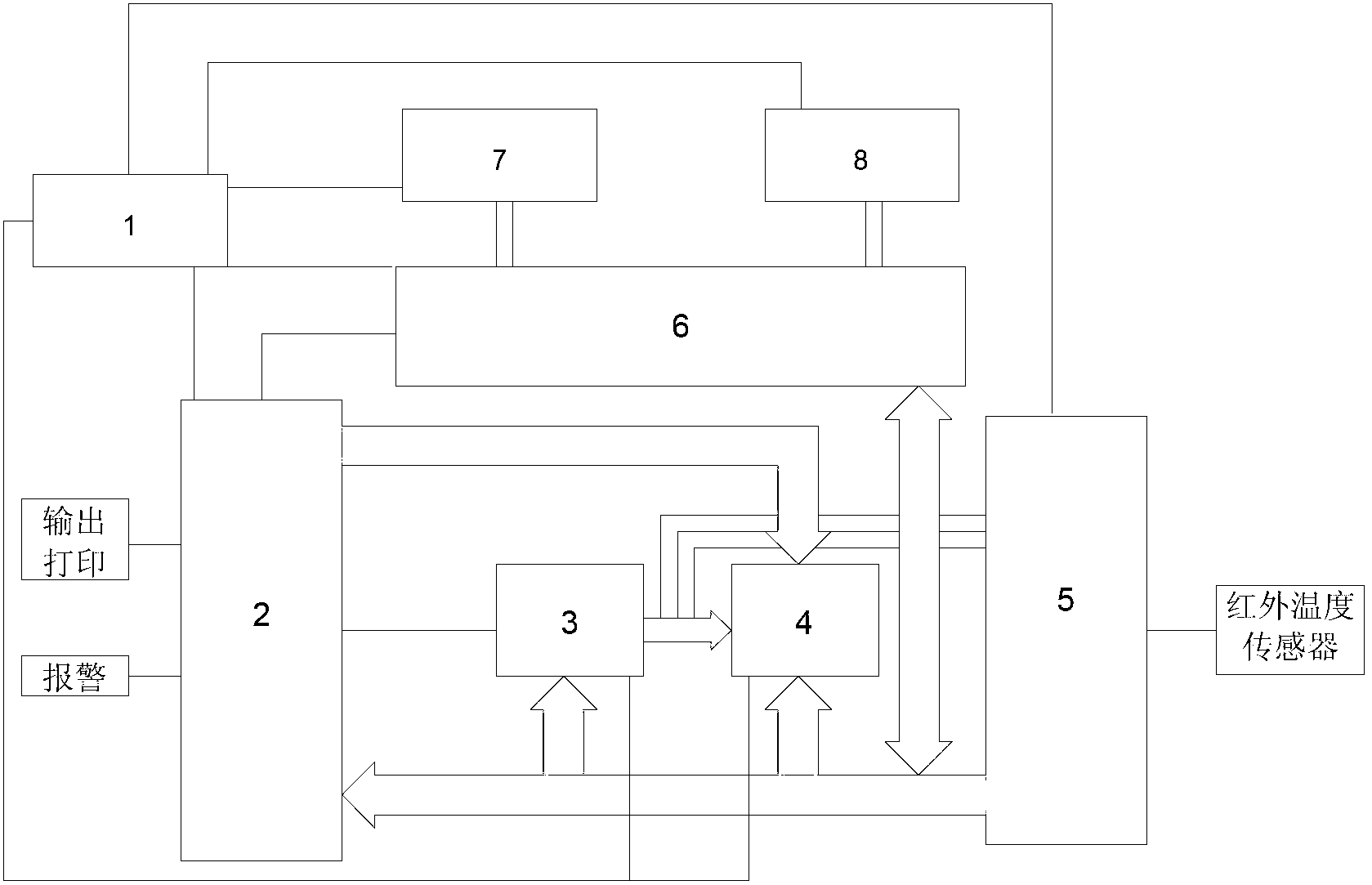

[0029] Such as figure 1 As shown, an AT89C51 single-chip infrared temperature measurement system of the present invention includes a power management module 1, a first control module 2, a second control module 3, a third control module 4, a signal acquisition module 5, a programmable interface module 6, and a scanning operation Module 7, temperature display module 8;

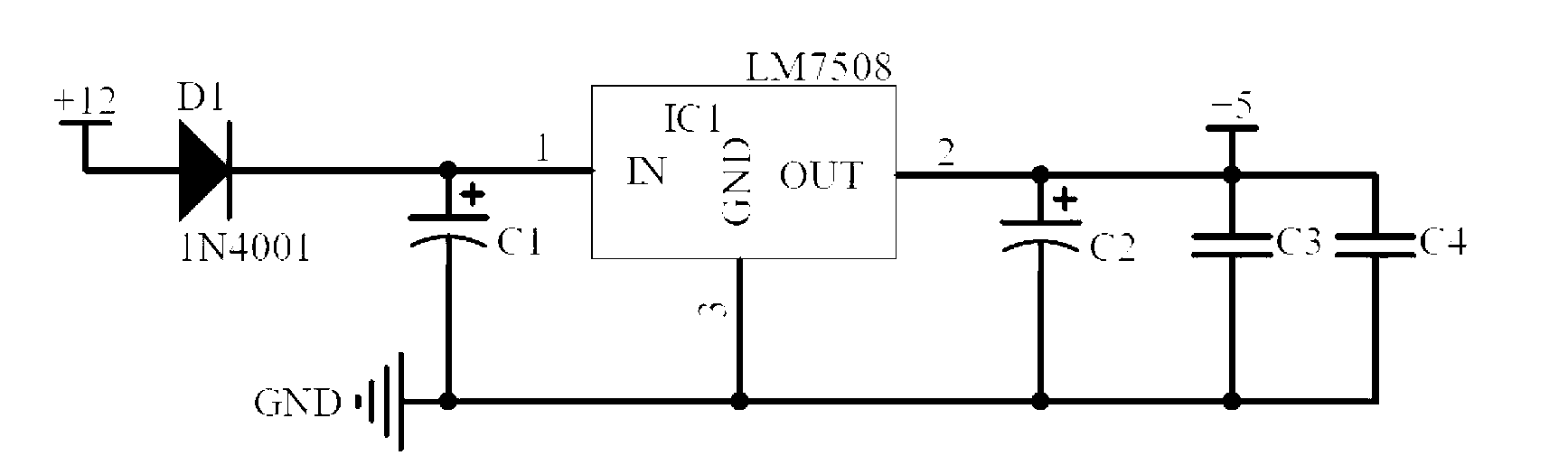

[0030] figure 2 Shown is the circuit schematic diagram of the power management module of the invention: the power management module includes IC1 (LM7508), the first anti-reverse connection diode D1, the first filter electrolytic capacitor C1, the second filter electrolytic capacitor C2, and the third filter capacitor C3 , the fourth filter capacitor C4.

[0031] The anode of the first anti-reverse connection diode D1 is connected to the given 12 total power supply, the cathode of the first anti-reverse connection diode D1 is connected to the positive pole of the first filter electrolytic capacitor C1 and pin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com