Thinned micro-electromechanical microphone module

A micro-electromechanical microphone, thin technology, applied in the direction of electrical components, transducer circuits, sensors, etc., can solve problems such as considerable difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to illustrate the structure, features and effects of the present invention in detail, the following will be further described in detail in conjunction with specific embodiments and accompanying drawings.

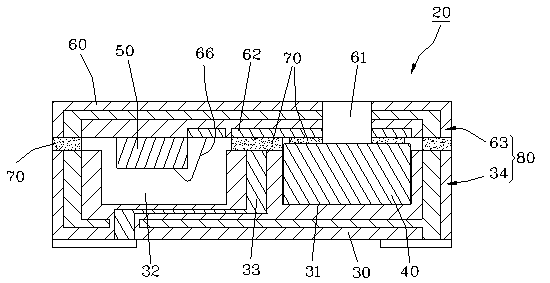

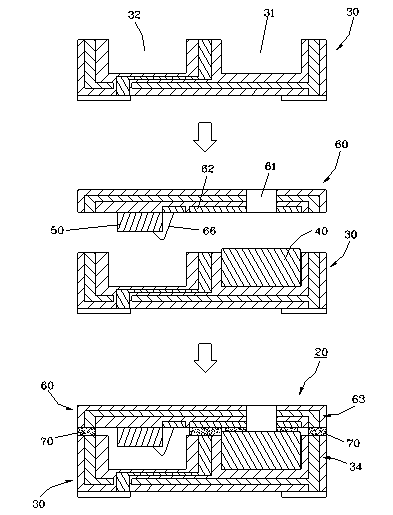

[0012] image 3 Shown is the thin micro-electro-mechanical microphone module 20 provided by this embodiment, including a first circuit board 30, a micro-electro-mechanical chip 40, an application-specific chip 50 (Application-specific integrated circuit, ASIC), and a first Two circuit boards 60 .

[0013] A first groove 31 and a second groove 32 spaced apart from each other are recessed from the top surface of the first circuit board 30 , and a first signal layer 33 and a first ground layer 34 are buried inside.

[0014] The MEMS chip 40 is accommodated in the first groove 31 of the first circuit board 30 and attached to the bottom wall of the first groove 31 .

[0015] The second circuit board 60 covers the top surface of the first circuit board 30 and use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com