Engineering machinery instrument casing

A technology of instrument housing and construction machinery, applied in the field of display instruments, can solve the problems of high scrap rate, increased process, easy cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

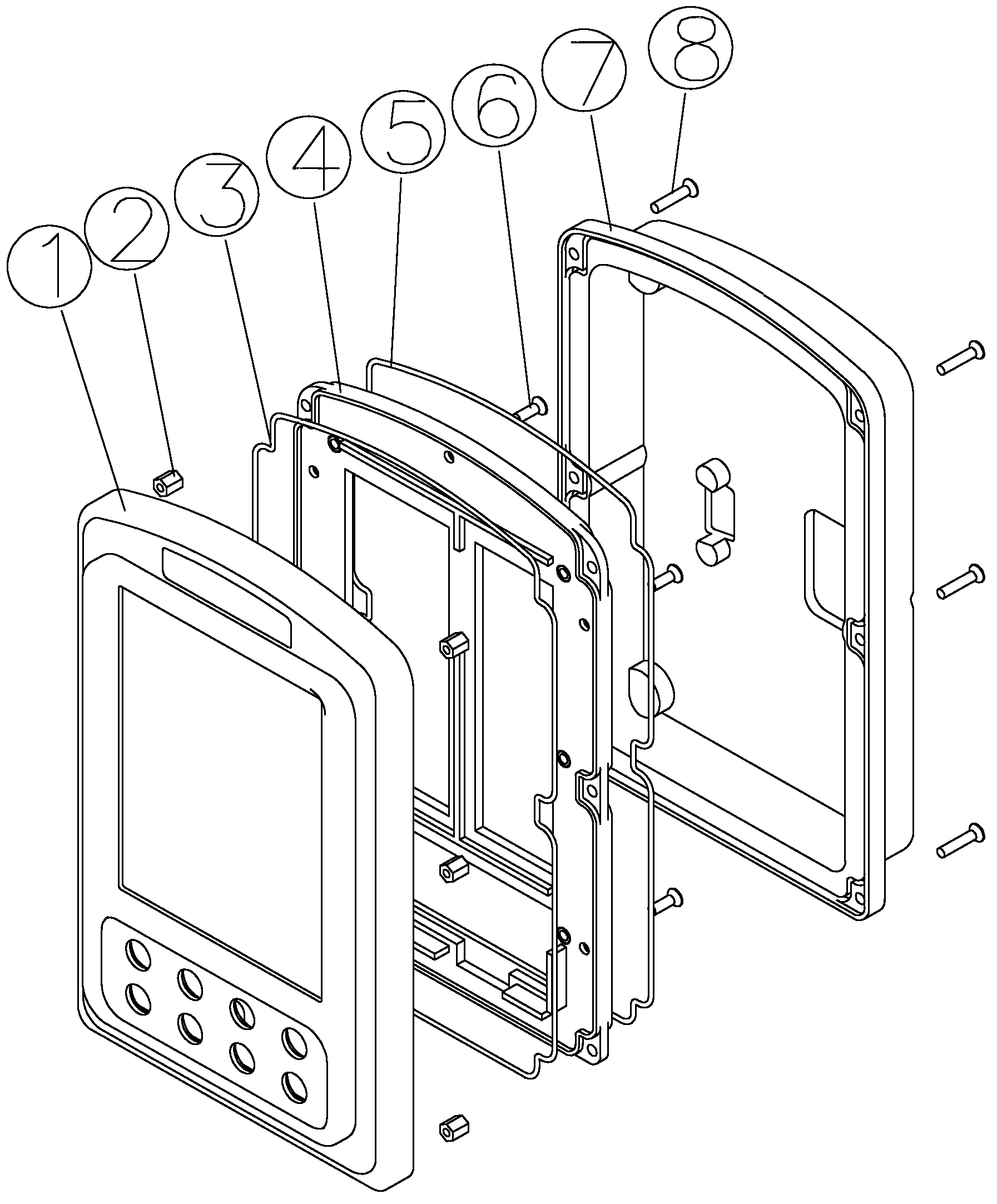

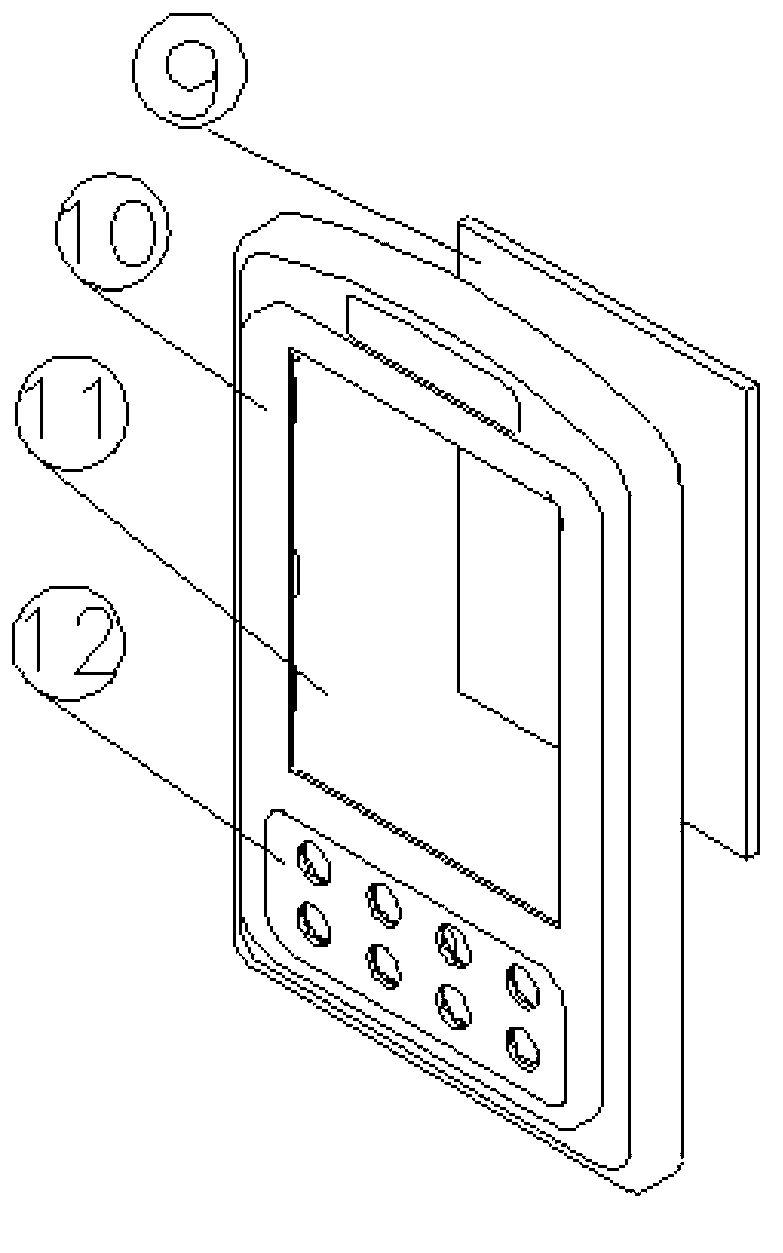

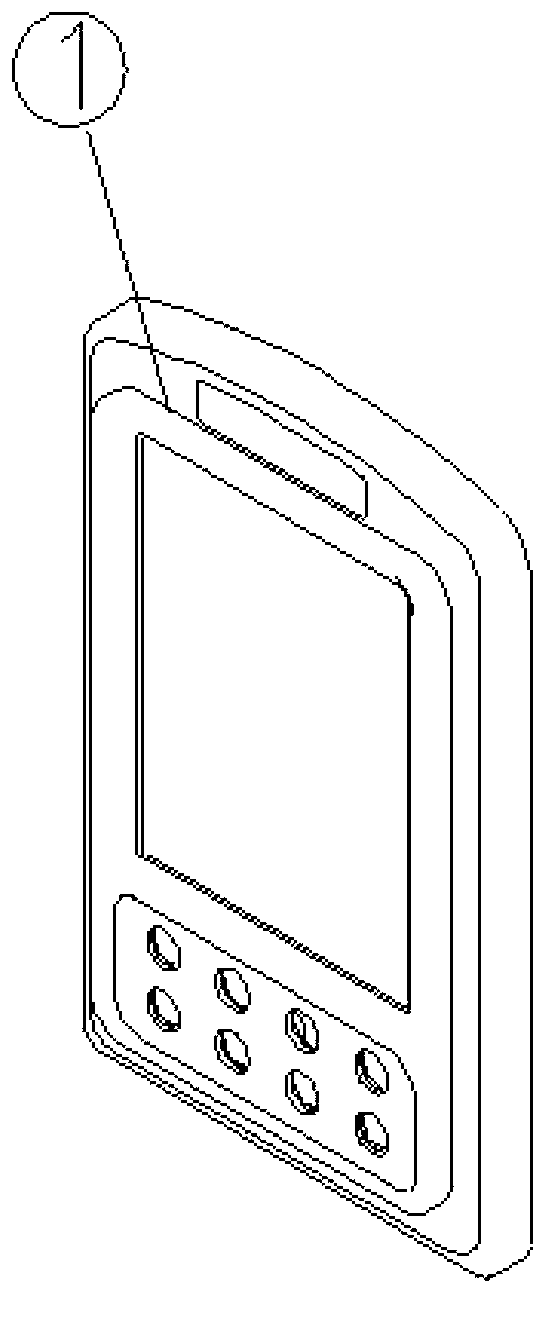

[0038] Below in conjunction with accompanying drawing, the present invention will be further described:

[0039] The engineering machinery instrument housing of the present invention is mainly composed of a combined panel 1, a combined pressing plate 4 and a combined back shell 7. The combined pressing plate 4 is placed between the combined panel 1 and the combined back shell 7, and the periphery of both sides of the combined pressing plate 4 is provided with waterproof Rib 20 and waterproof rib 21 (see Figure 5-2 As shown), the combined pressure plate 4 is provided with a hexagonal stud hole 18 on the outer side of the waterproof rib, and the combined pressure plate 4 is provided with a cross countersunk screw hole 19 on the inner side of the waterproof rib; the combined panel 1 is in contact with the combined pressure plate 4 One side is provided with a waterproof groove 15 corresponding to the waterproof rib 21, the waterproof groove 15 is provided with a sealing strip 3 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com