Ultrasonic array transducer and production method thereof

An ultrasonic array and transducer technology, which is applied in ultrasonic/acoustic/infrasonic diagnosis, ultrasonic diagnosis, infrasonic diagnosis, etc., can solve problems such as position deviation, ultrasonic image deviation, structural instability, etc., to reduce depth and increase stability Sexuality, the effect of a wide range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

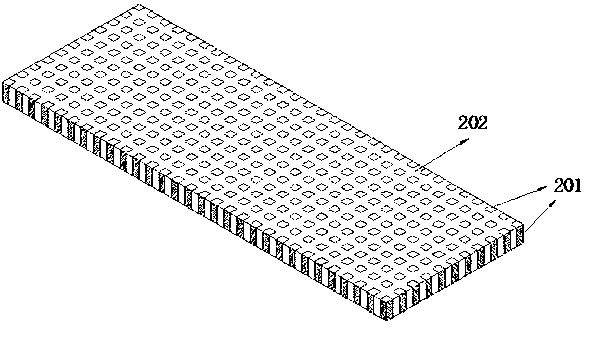

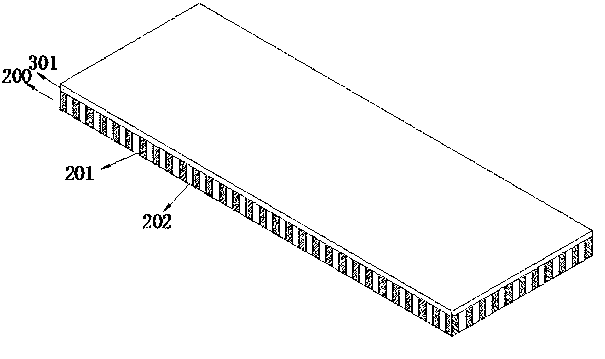

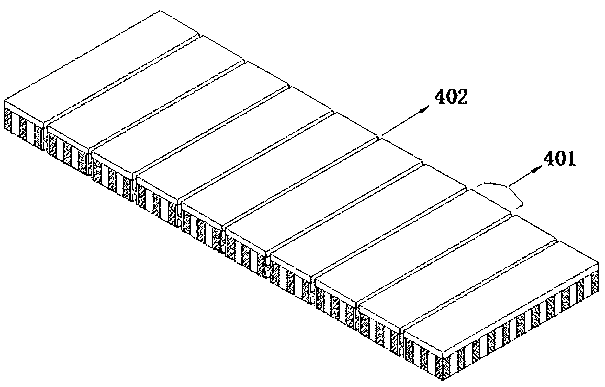

[0031] as attached Figure 1-4 As shown, an ultrasonic array transducer, the array element includes a piezoelectric layer (200) and a matching layer (301). The matching layer (201) between the array elements (401) is completely separated, and each array element (401) Both the transmitted and received ultrasonic energy cannot be coupled to other units through the matching layer, which effectively reduces crosstalk and suppresses the generation of noise signals. The piezoelectric layer (200) between the array elements (401) is not completely separated, so that each array element (401) can be distinguished from each other while still providing support for the formation of the array, maintaining a relatively fixed distance between the array element...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap