Tapered embedded locating method for silicon-based ceramic core and aluminium-based ceramic shell

A technology of ceramic cores and aluminum-based ceramics, applied in the direction of cores, molds, mold components, etc., can solve the problems of blade size out-of-tolerance, inconsistency, blade deviation, etc., to solve positioning interference, additional The effect of low cost and reducing blade size out-of-tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

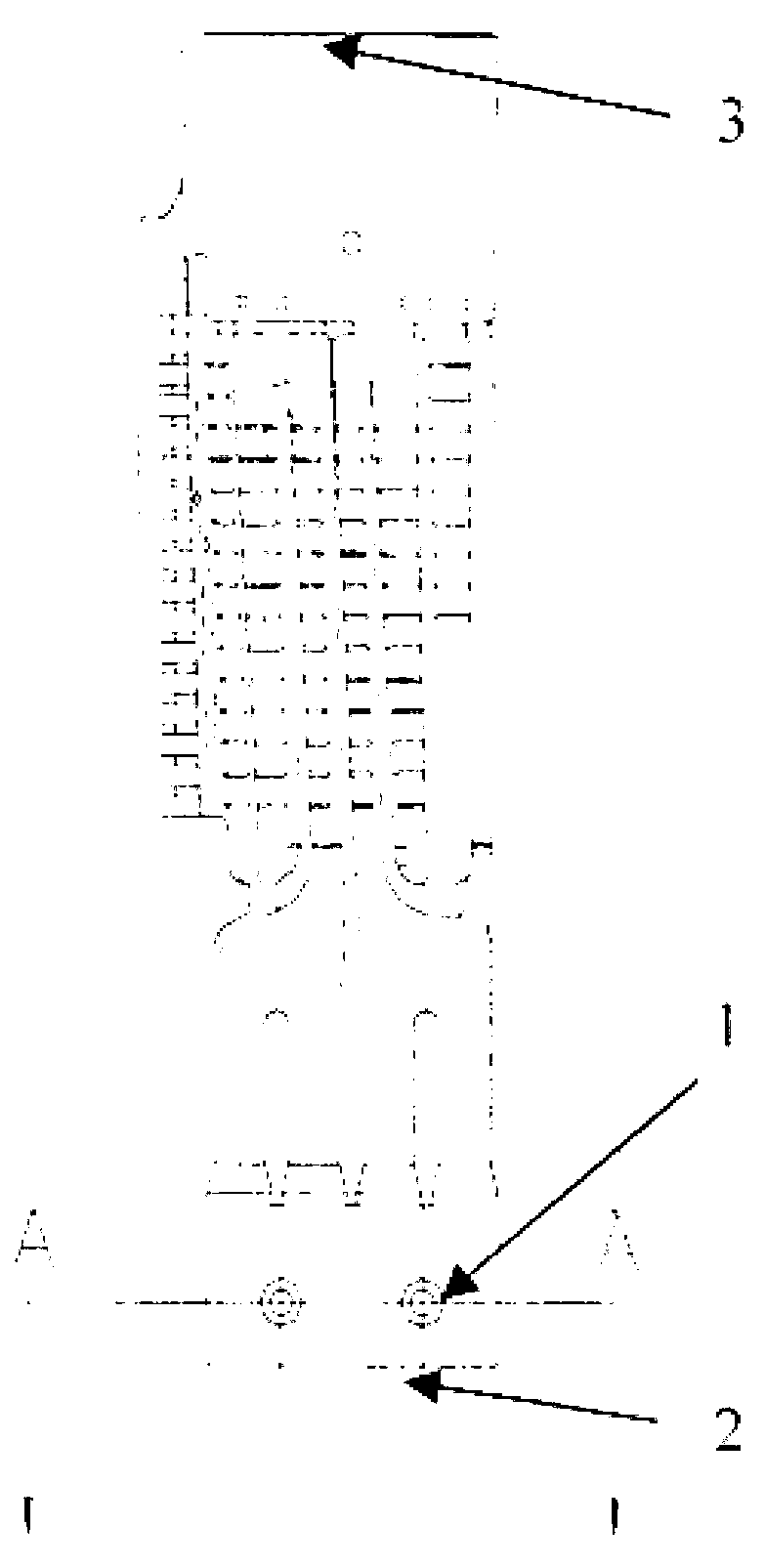

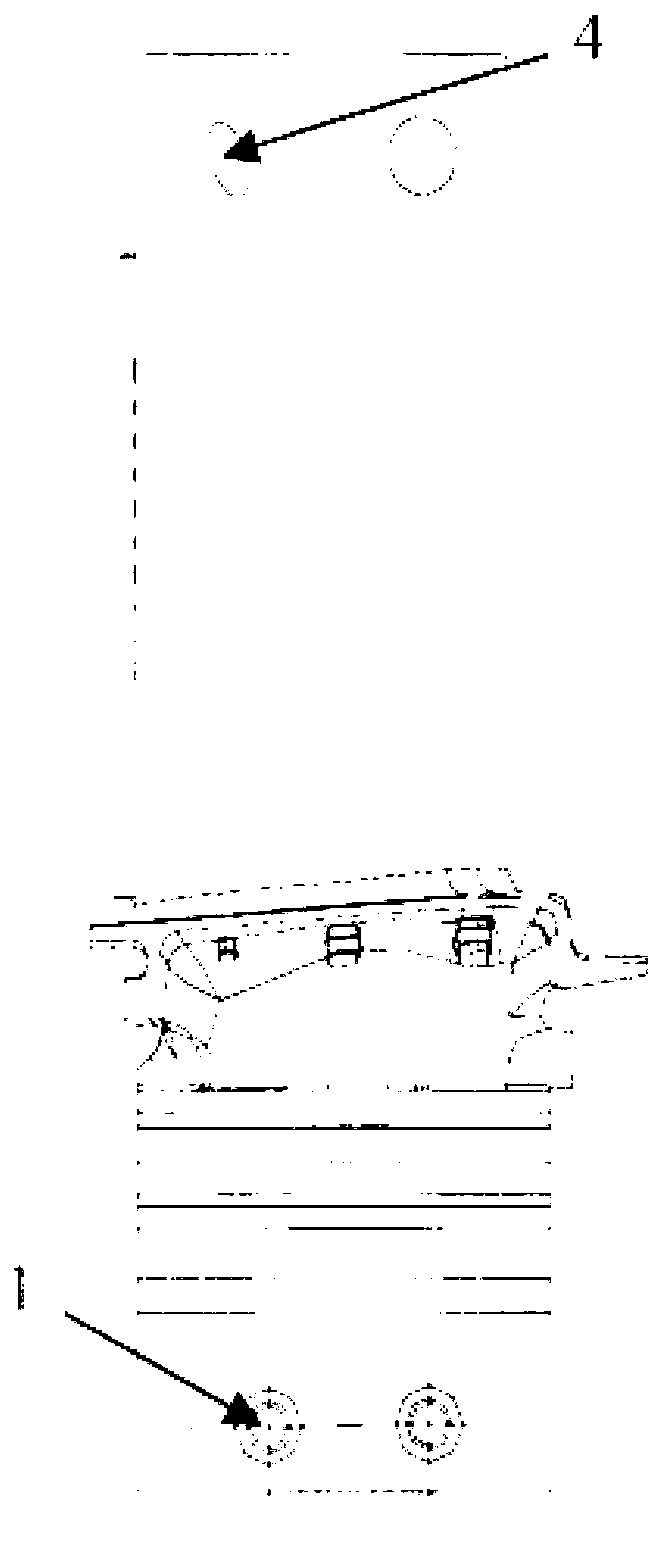

[0036] The tapered embedded positioning method of silicon-based ceramic core and aluminum-based ceramic shell is characterized in that:

[0037] 1) Design a positioning groove at the positioning surface of the ceramic core. The positioning groove is specifically a tapered hole groove or a square tapered hole groove; one or two positioning grooves are selected to avoid over-positioning; when one positioning groove is selected, a square cone is selected Shaped hole groove, when two positioning grooves are selected, the two positioning grooves are specifically tapered hole grooves;

[0038] 2) In the design of the wax model, the wax piece is provided with a positioning hole corresponding to the position of the positioning groove in 1);

[0039] 3) For other auxiliary positioning, choose the facet positioning method; the weak area where the blade exhaust seam is located is set from the curved end; the thickness is controlled at 0.1mm to 0.5mm.

[0040] In the tapered embedded pos...

Embodiment 2

[0050] The main content of this embodiment can be understood with reference to Embodiment 1, see the attached Figure 1-6 .

Embodiment 3

[0052] The main content of this embodiment can be understood with reference to Embodiment 1, see the attached Figure 7-13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com