Roof steel structure pairing device in railway vehicle

A technology for rail vehicles and steel structures, applied in workpiece clamping devices, manufacturing tools, etc., can solve problems such as low production efficiency, time-consuming and laborious, and achieve the effects of improving production efficiency, ensuring tooling stability, and improving plant utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

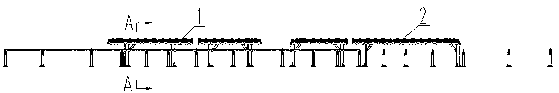

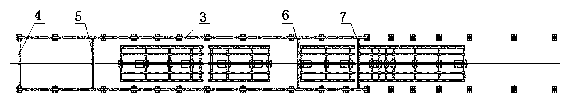

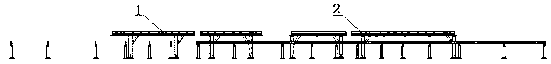

[0011] refer to figure 1 , 2 , the present invention is made up of TC car positioning frame body 1, MC car positioning frame body 2, accompanying frame body, supporting leg 11, support 10, curved beam positioning body 8, pressing block 9, edge beam positioning block 12. The accompanying frame body is made up of two longitudinal beams 3 and four beams 4,5,6,7. The positioning frame body of the TC car and the positioning frame body of the MC car are each divided into two parts, and a channel is formed by breaking from it. The distance from the beam 7 on the accompanying frame body to the left end positioning reference is 19700 mm. Here is the channel of the positioning frame body 2 of the MC car. , the crossbeam 4 on the accompanying frame body is 20180 millimeters away from the right end positioning datum, here is the channel place of the TC car positioning frame body 1, and the accompanying frame body passes through the channel and is set. The positioning frame body of TC ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com