System and method for printing brand mark on automobile glass

A technology for automotive glass and printing systems, applied in printing, printing machines, rotary printing machines, etc., can solve problems such as not being able to meet high production capacity, improve printing quality and printing efficiency, improve self-adaptability, and improve unloading efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The content of the present invention will be further described below in conjunction with the accompanying drawings.

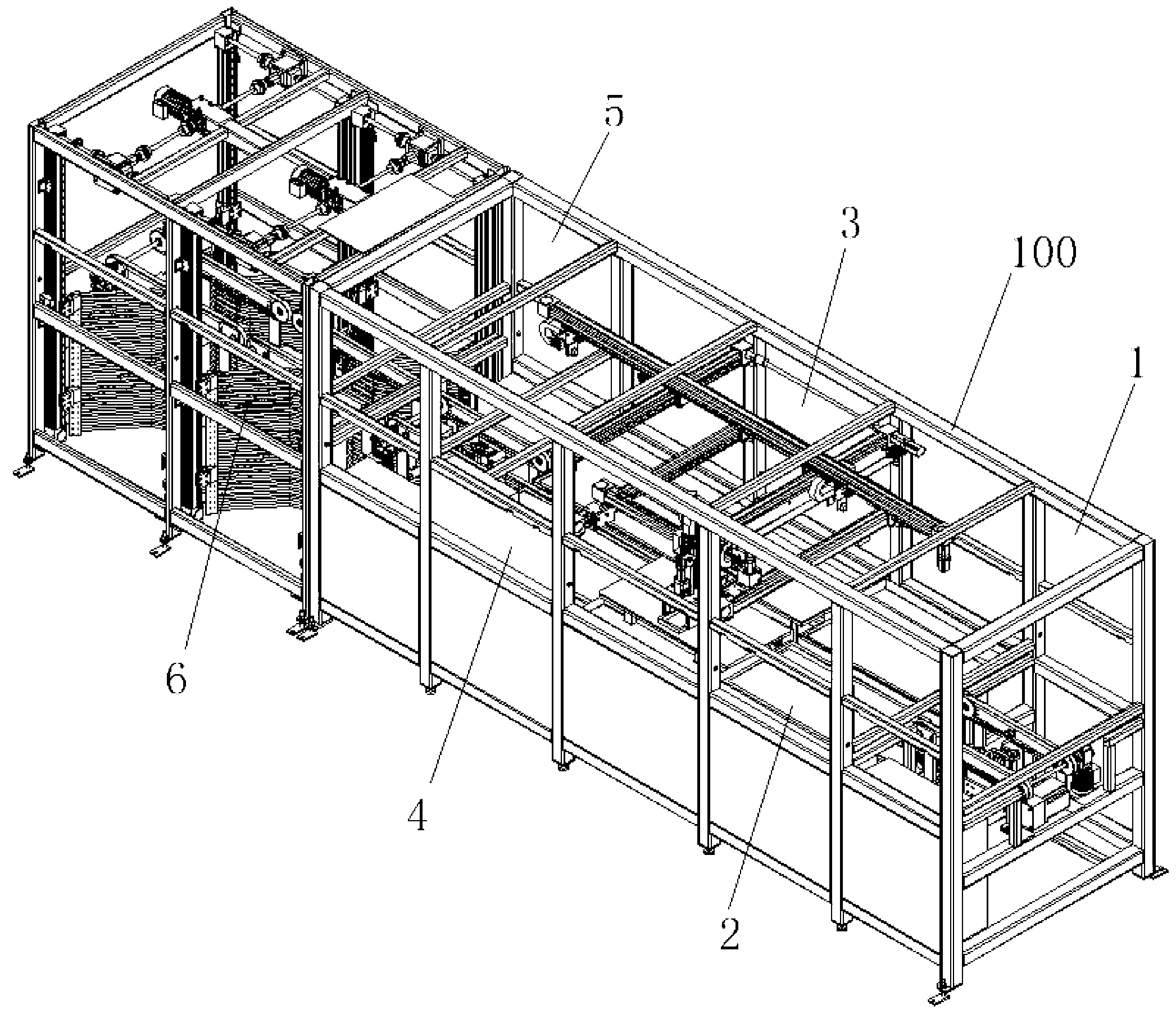

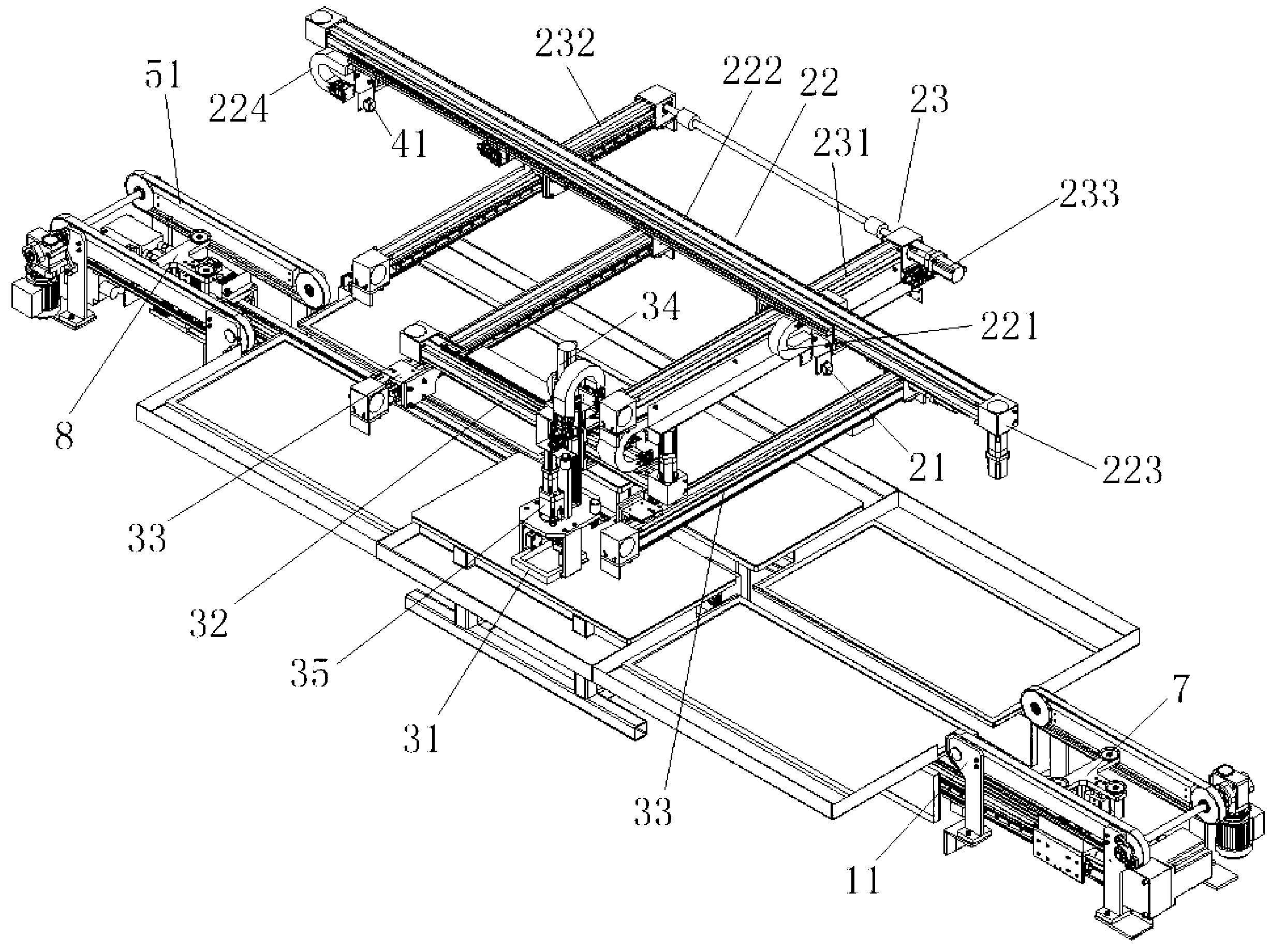

[0036] like figure 1 As shown, a kind of automobile glass trademark logo printing system according to the present invention includes an upper area 1, an image acquisition area 2, a printing area 3 and a lower area 5 arranged in sequence, as well as a frame 100 and a computer not shown in the figure. Wherein, the upper sheet area 1 is used to transfer the automobile glass to be printed to the set upper sheet position, the image acquisition area 2 is used to collect the actual position contour image of the area to be printed on the automobile glass, and the printing area 3 is used for Carry out trademark logo printing on the area to be printed on the automobile glass, the lower area 5 is used to transport the automobile glass that has completed the trademark logo printing, and the frame 100 is used to set the upper area 1, the image acquisition area 2, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com