Emulsion explosive mixing and loading truck with double pumping system

An emulsion explosive and pumping system technology, which is applied to explosives, explosives processing equipment, offensive equipment, etc., can solve problems such as poor work reliability, and achieve the effect of ensuring operations, avoiding construction pauses, and reducing purchase and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

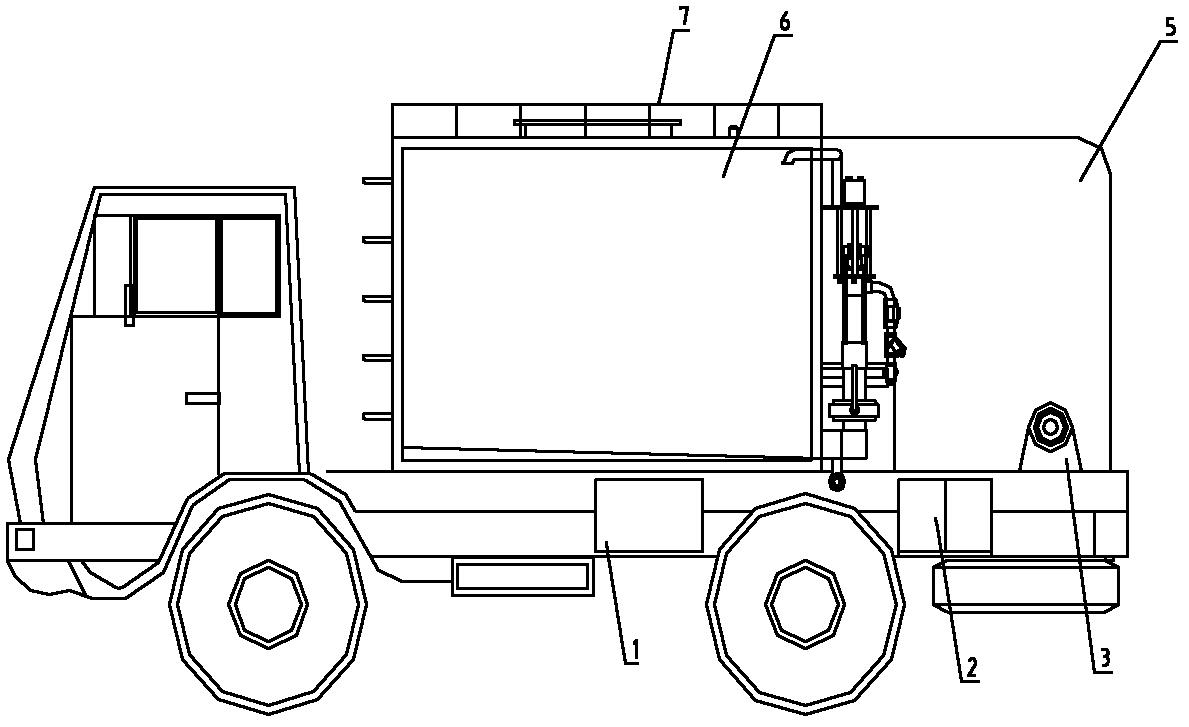

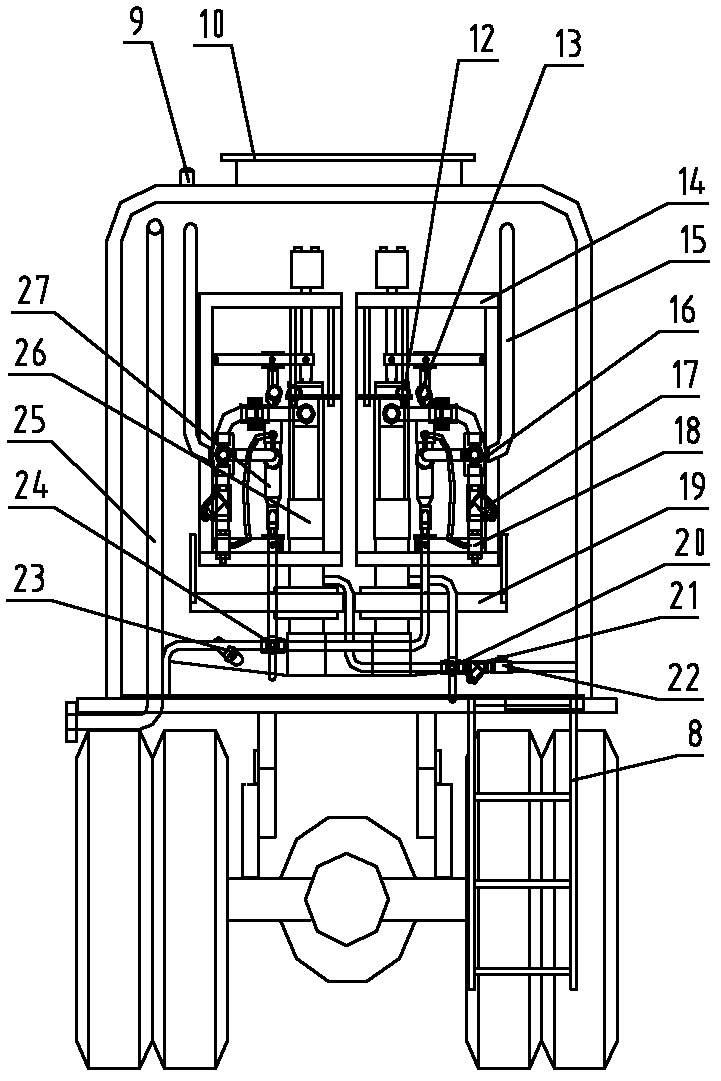

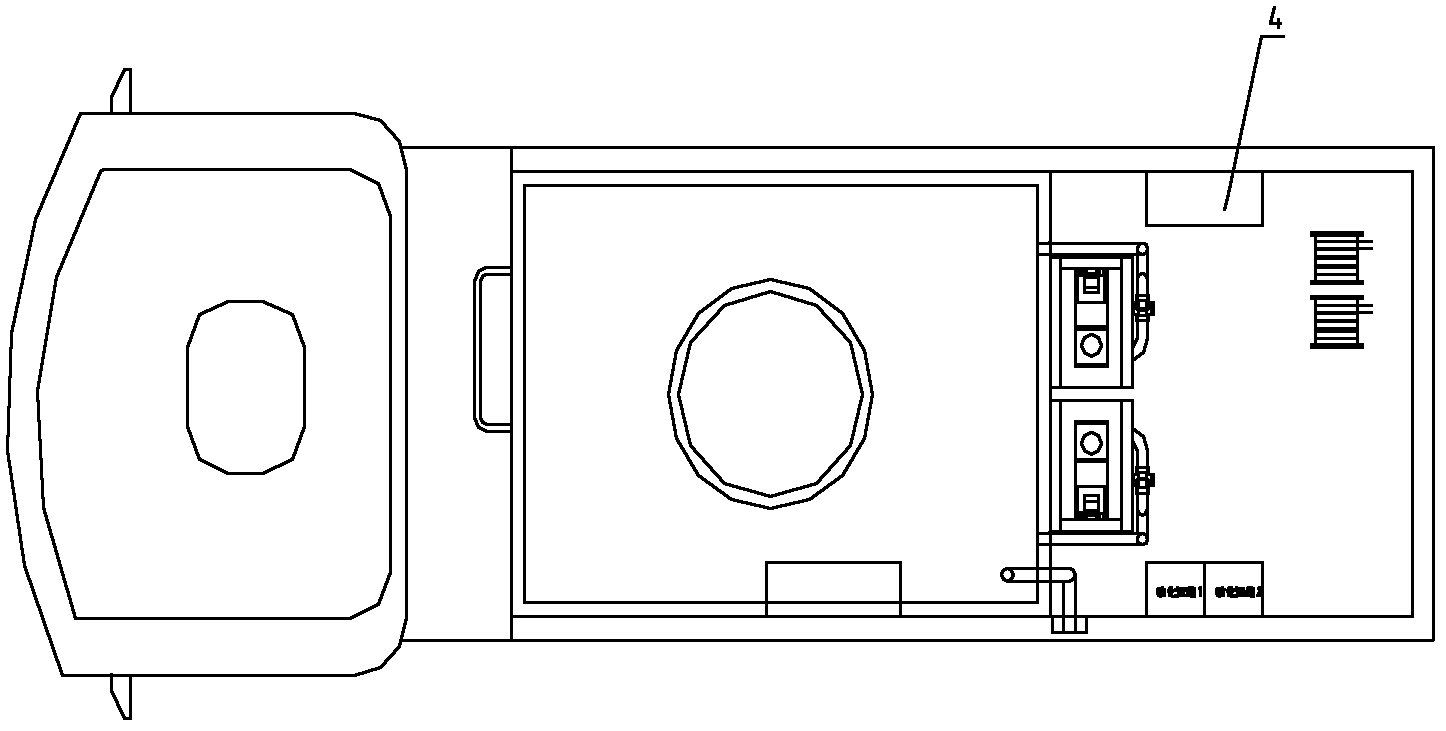

[0032] Such as figure 1 , 2 , 3, which is a schematic structural view of the double pumping system emulsion explosive mixing vehicle of the present invention.

[0033] The dual-pumping system emulsion explosive mixed vehicle of the present invention comprises a car body and a compartment 5, the compartment 5 is provided with an emulsification matrix tank 6, a hydraulic oil tank 1 and a sensitizing liquid tank 2 are arranged on the chassis of the car body, and the rear part of the compartment 5 is arranged There is a coil machine 3 and a water tank 4, and the upper end of the emulsification matrix tank 6 is provided with a manhole and a manhole cover 10, and a breathing valve 9 is also provided. A movable ladder 8 is provided at the rear of the compartment 5, and a lifting guardrail 7 is provided at the top of the compartment 5.

[0034] The emulsification matrix is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com