Coaling method for a coke oven vehicle

A coke oven and coal charging technology, which is applied in the coal charging field of 7.63m coke oven vehicles, can solve problems such as gas leakage and smoke leakage at the furnace mouth, and achieve the effects of reducing the temperature of the furnace top space, increasing coke production, and increasing the amount of coal loaded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

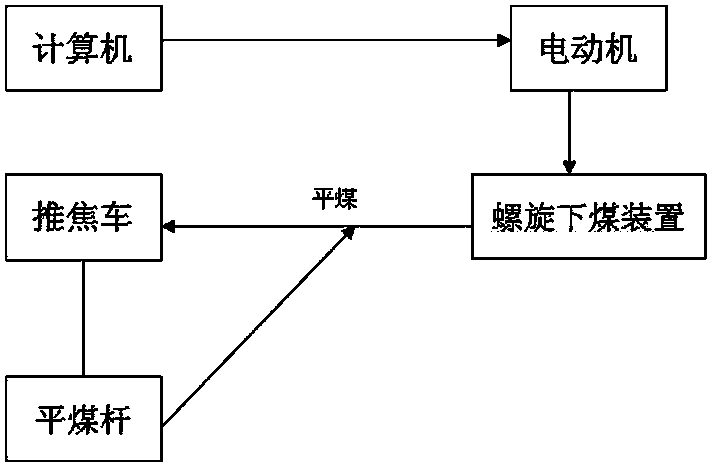

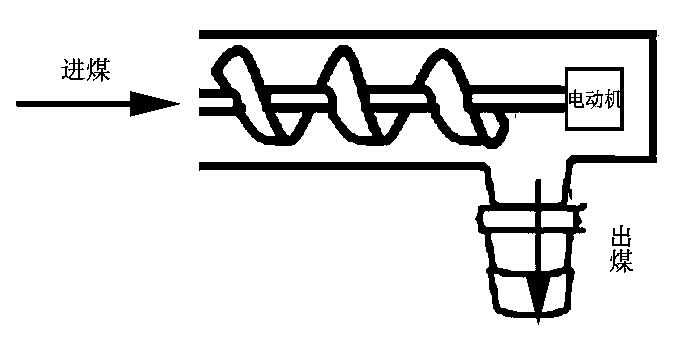

[0012] Such as figure 1 and figure 2 As shown, a 7.63m coke oven vehicle coal charging method makes the four coal inlets of the coke oven carbonization chamber correspond to the coal lower coal outlets of the four spiral coal lowering devices of the coal loading car, and the motor starts to be controlled by an industrial automation logic controller. Running, the motor is controlled by a frequency converter, and the industrial automation logic controller adjusts the instantaneous and total coal loading volume of the coal loading car by controlling the motor, and adjusts the motor in real time according to the pre-loading coal volume of the coal hopper (coke oven carbonization chamber). Rotation speed, so as to control the screw speed of the screw rod of the coal loading car spiral unloading device, so that the four spiral unloading coal devices can delay the unloading of coal, and 90% of the pre-loaded coal in the coke oven carbonization chamber can be completed after the four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com