Methylisothiazolinone stabilizing system for liquid detergent

A technology of methylisothiazolinone and chloromethylisothiazolinone, which is applied in the field of stabilization systems of methylisothiazolinone preservatives, and can solve the problems of difficulty in guaranteeing the stability of preservatives and low concentration of use , to achieve the effect of inhibiting microbial growth and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Applied to tableware fruit and vegetable detergent

[0025] According to the formulation content in Table 1, add surfactant, chelating agent, pH regulator, stabilizer, essence and viscosity regulator into deionized water in a certain order, stir until dissolved evenly, and adjust the target pH to 7.0. Samples were drawn for inspection according to quality standards. Qualified products can be filled into finished dishwashing detergent compositions after being left to stand until there is basically no foam.

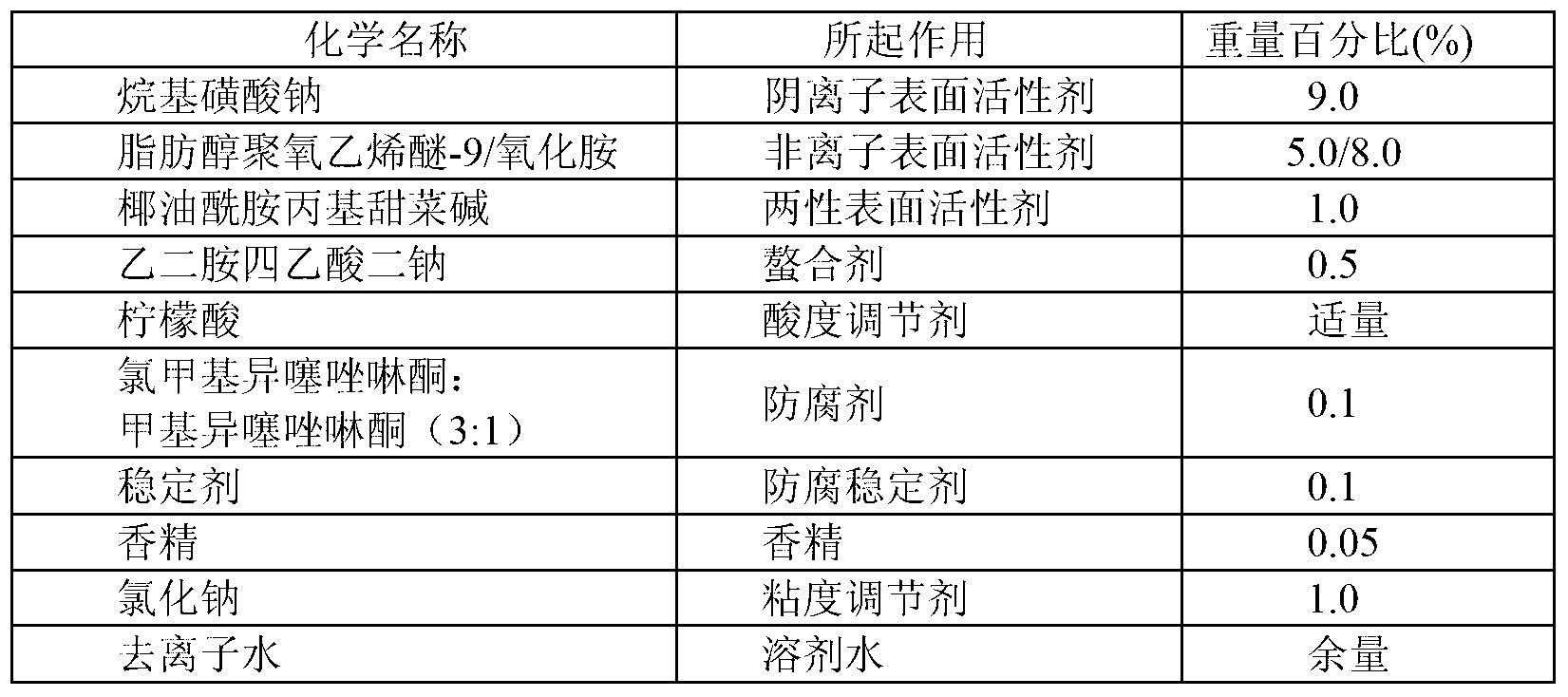

[0026] The basic formula composition of the dishwashing detergent composition of table 1 embodiment 1

[0027]

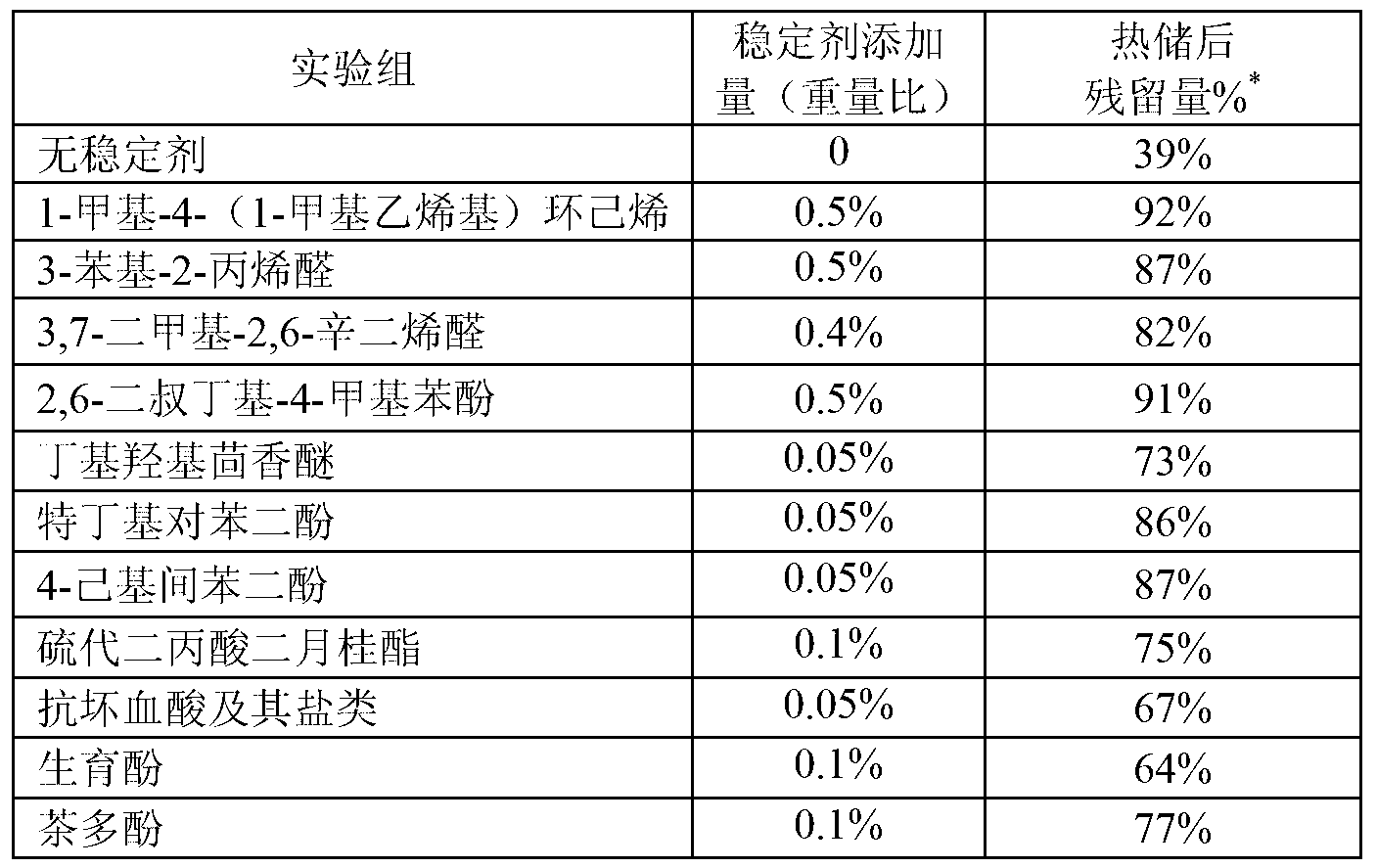

[0028] The basic formula refers to Example 1, the initial content of preservative is 15ppm, and the amount of stabilizer is added according to Table 2. After the dishwashing detergent prepared in Example 1 and the dishwashing detergent without stabilizer were stored at high temperature (50 degrees Celsius for 4 weeks), it was found that the stabilit...

Embodiment 2

[0033] Applied to tableware fruit and vegetable detergent

[0034] According to the formula content in Table 3, surfactants, chelating agents, pH regulators, stabilizers, flavors and viscosity regulators were added to deionized water in a certain order, stirred until they were evenly dissolved, and the pH was adjusted to 8.0. Samples were drawn for inspection according to quality standards. Qualified products can be filled into finished dishwashing detergent compositions after being left to stand until there is basically no foam.

[0035] The formula composition of the dishwashing detergent composition of table 3 embodiment 2

[0036]

[0037] After the dishwashing detergent prepared in Example 2 and the dishwashing detergent without adding stabilizer were stored at high temperature (50 degrees Celsius for 4 weeks), it was found that the dishwashing detergent preservative added with 2,6-di-tert-butyl-4-methylphenol The stability was significantly better than that of the...

Embodiment 3

[0041] Used in fabric detergent

[0042] According to the formulation content in Table 5, add surfactant, fluorescent whitening agent, pH regulator, preservative, stabilizer, essence and viscosity regulator into deionized water in a certain order, and stir until dissolved evenly. Samples were drawn for inspection according to quality standards. Qualified products can be filled into finished fabric detergent compositions after standing until there is no foam substantially.

[0043] The formula composition of the fabric detergent composition of table 5 embodiment 3

[0044]

[0045] After high-temperature heat storage (50 degrees Celsius for 4 weeks) between the fabric detergent prepared in Example 3 and the fabric detergent without added stabilizer, it was found that the stability of the fabric detergent preservative added with dilauryl thiodipropionate was significantly better than The results of the experimental group without stabilizer are shown in Table 6.

[0046] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com