Thread casting head distributing plate

A casting head and distribution plate technology, applied in spinneret assemblies, textiles and papermaking, etc., can solve the problems of complex distribution plate structure, inconvenient use, uneven partial pressure of polyester melt, etc., and achieve the effect of partial pressure Good, optimized distribution, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

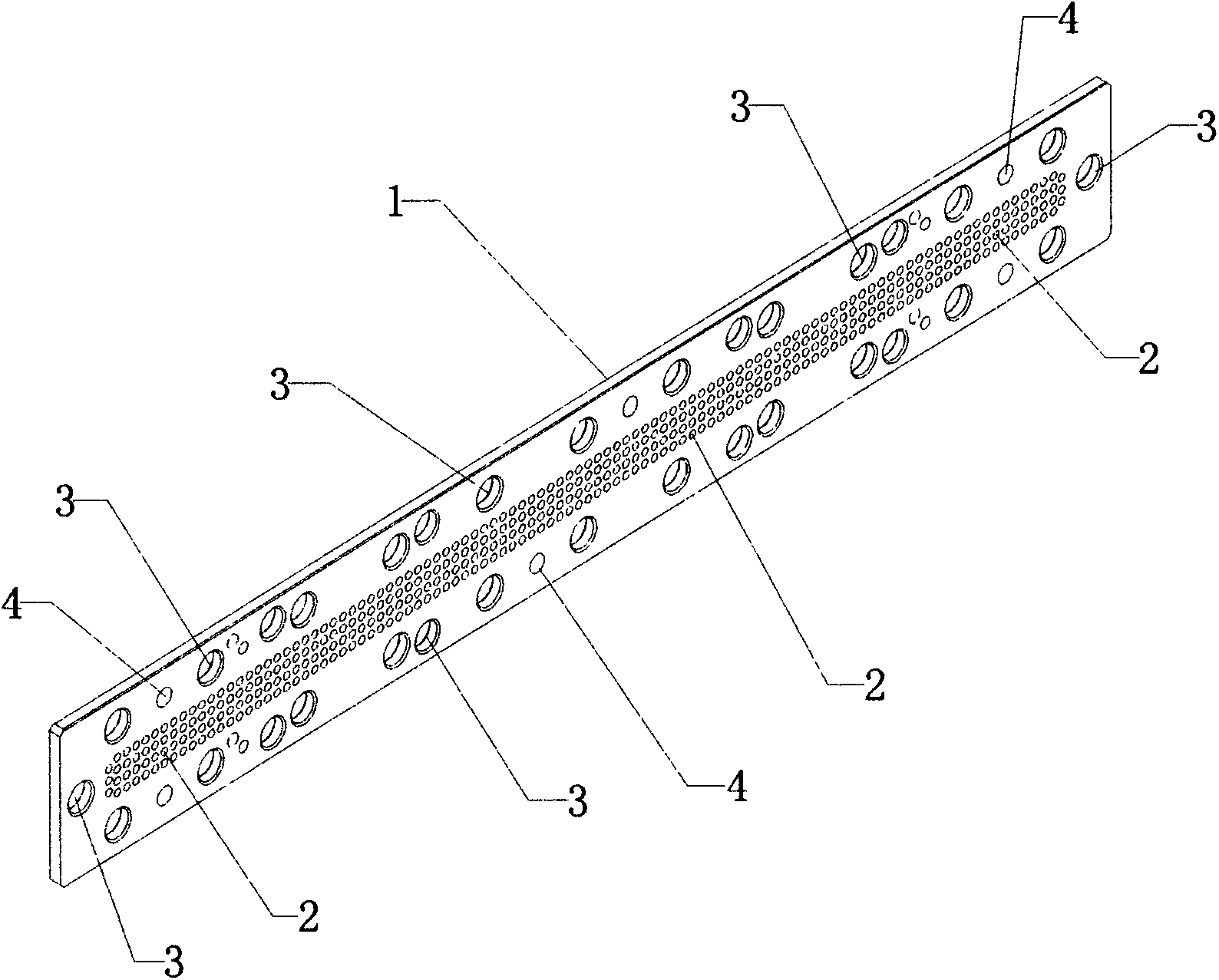

[0012] Such as figure 1 As shown, a distributing plate for wire strand casting with heads includes a rectangular plate body 1, the middle part of the end face of the rectangular plate body 1 is provided with a number of splitting holes 2 distributed in a rectangular array, and the end face of the rectangular plate body 1 is close to the surrounding edges A number of fixing holes 3 and positioning holes 4 are provided.

[0013] In the distribution plate for wire strand casting with heads of the present invention, the inner surface of the wire dividing hole 2 and the end surface of the rectangular plate body 1 are transitioned by a circular arc.

[0014] In the distributin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com