Pretightening-force-adjustable friction-type anchorage device applied to fiber-reinforced composite material rib inhaul cable

A composite material, fiber reinforced technology, applied in the direction of building reinforcements, bridge parts, structural elements, etc., can solve the problems of bending at the end of the bonding area, bending at the end of the holding area, shear fatigue, etc. Rotational friction, elimination of transverse shear, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

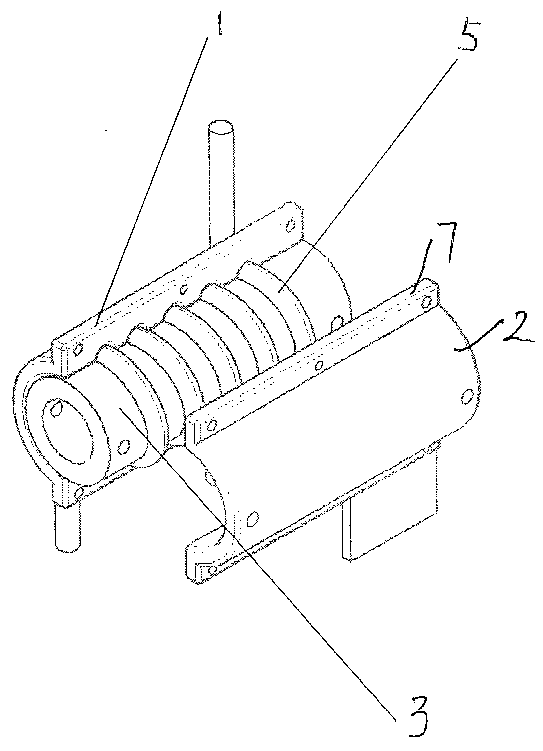

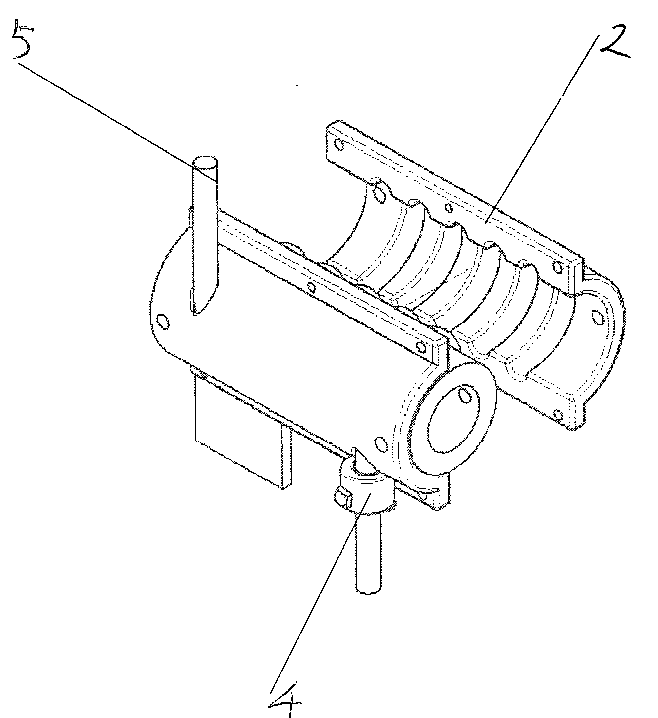

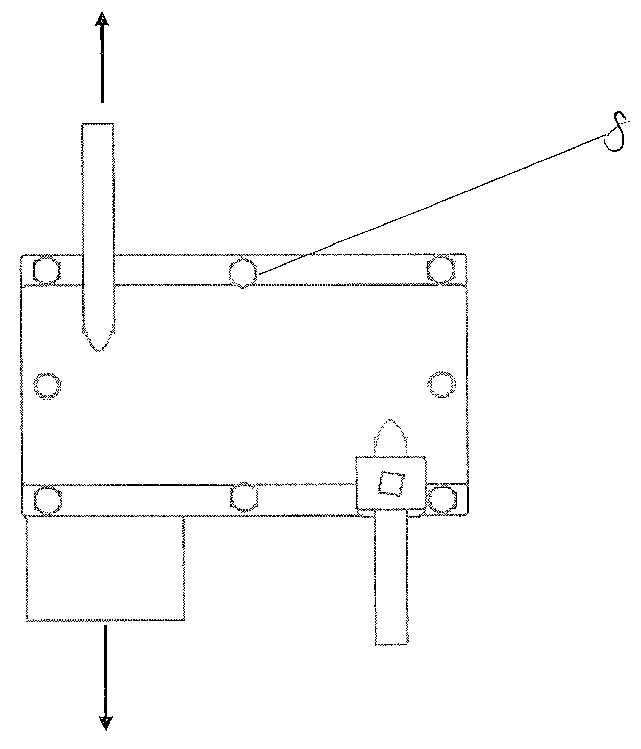

[0019] An adjustable pre-tightening force friction anchor applied to fiber-reinforced composite tendon cables, including two cover plates (A) 1 and (B) 2 with spiral grooves, and a column core with spiral grooves 3. A cable fastener 4; wherein the cross section of the spiral groove in the cover plate and the column core is semicircular with the same diameter, and the spiral grooves in the two cover plates and the column core cooperate with each other to form a space spiral groove with a circular cross section ; The cover plate A has an inlet hole and an output hole respectively at the starting point and the end point of the spiral groove, and the FRP tendon cable 5 with the same diameter as the spiral groove section passes through the inlet hole of the cover plate A and is wound in the spiral groove in the column core , and pass through the output hole of the cover plate A, the FRP tendon cable is wrapped by the surface of the space rotation groove formed by the cover plate and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com