Molded lining support structure and construction method for soft soil ground layer

A supporting structure and construction method technology, applied in shaft lining, tunnel lining, earthwork drilling and mining, etc., can solve the problems of low mechanization, long construction period, large land subsidence, etc., and achieve high safety and high mechanization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

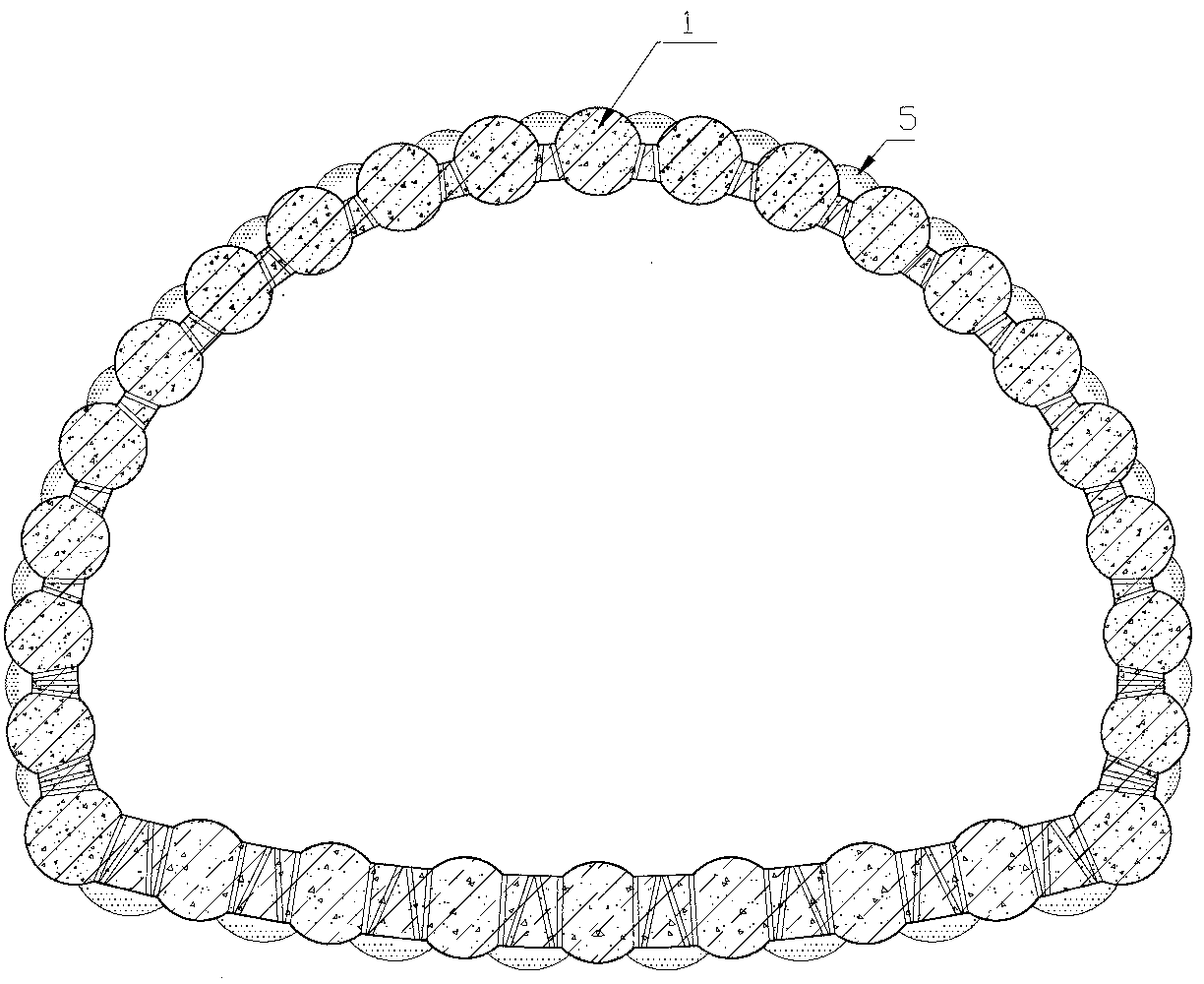

[0071] figure 1 Shows a sectional view of the molded lining support structure in Embodiment 1 of the present invention, as figure 1 As shown, the molded lining support structure includes a closed lining support 1 and a first grouting reinforcement area 5 arranged on the periphery of the closed lining support 1 . The closed lining support 1 in this embodiment is described as an example of a closed lining support surrounded by two arc-shaped lining supports. Of course, the cross-sectional shape of the closed lining support shown in this embodiment is only exemplary, and any shape that constitutes a closed structure falls within the protection scope of the present invention. For example, the cross-sectional shape of the closed lining support can also adopt a circle Shapes, rectangles and other regular graphics.

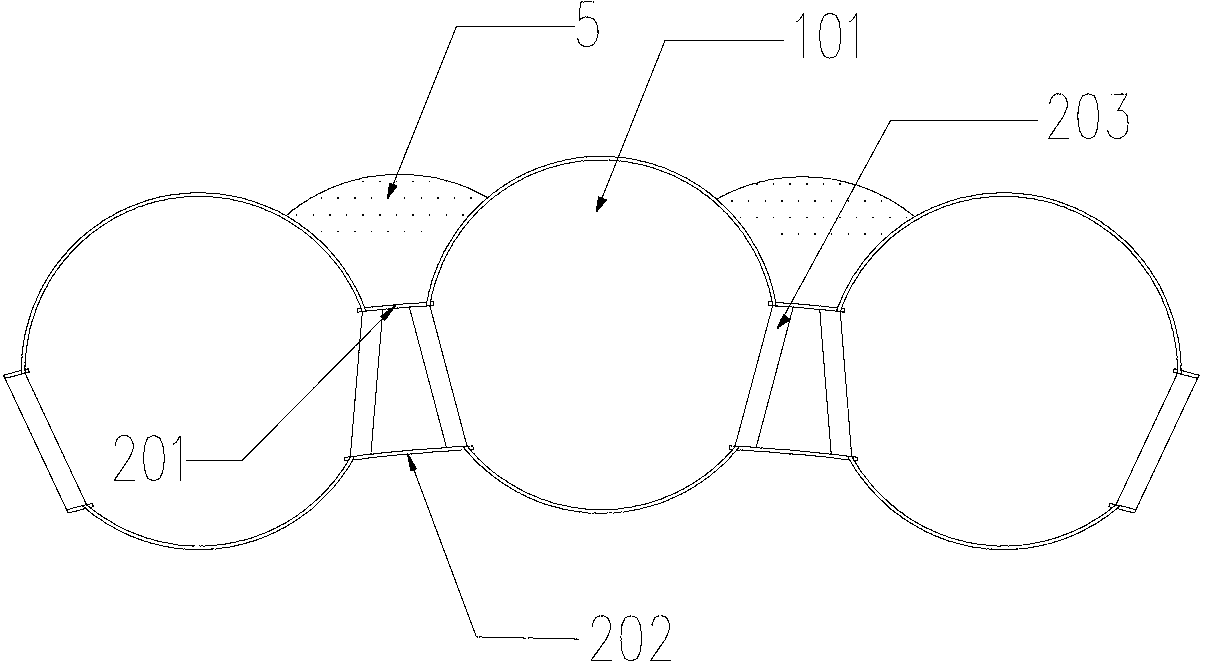

[0072] figure 2 A partial enlarged view of the closed lining support is shown. Such as figure 2 As shown, the closed lining support includes several steel pipes a...

Embodiment 2

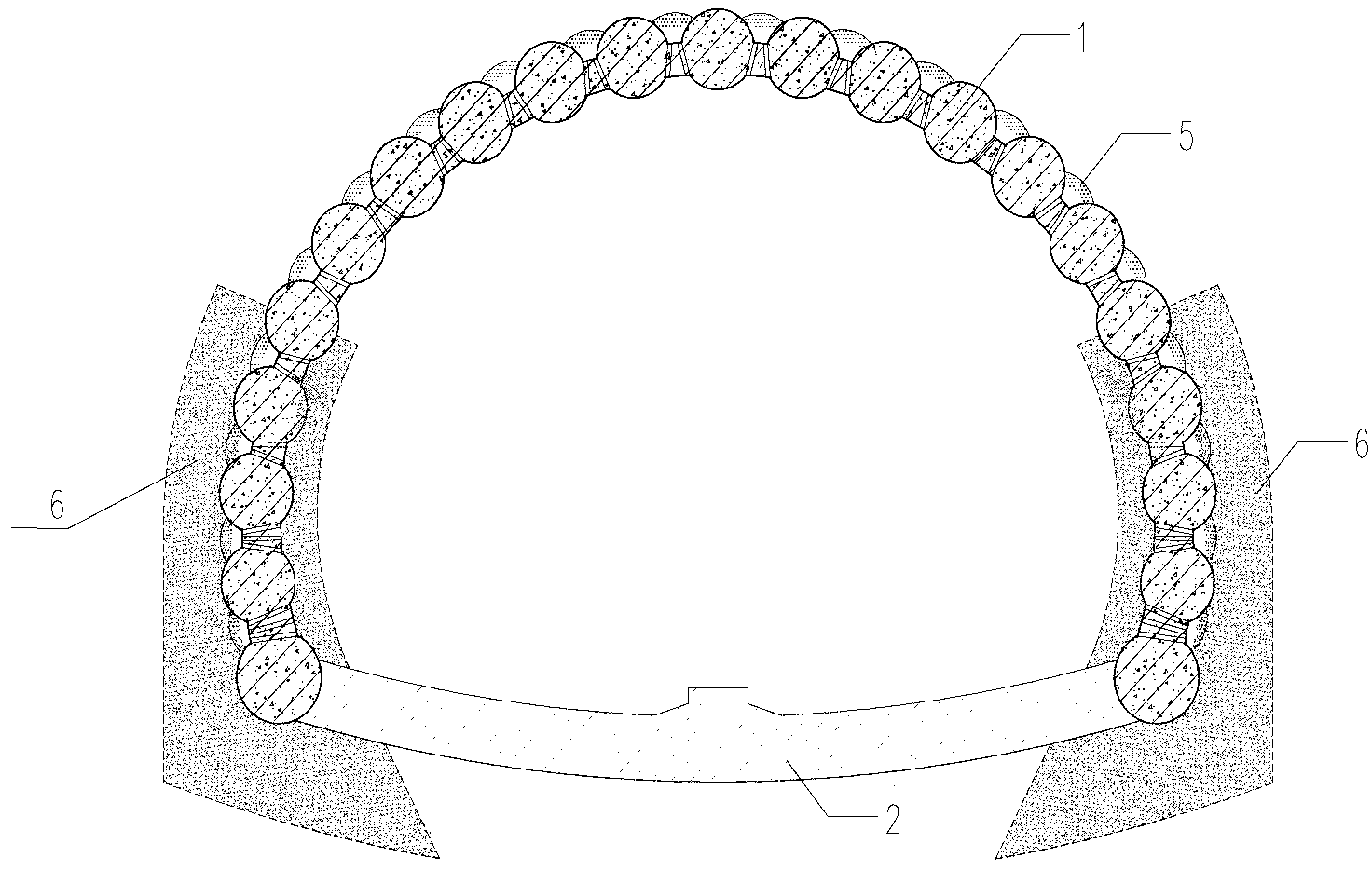

[0080] image 3 A cross-sectional view of the molded lining support structure in Embodiment 2 of the present invention is shown. Such as image 3 As shown, the molded lining support structure includes an open lining support and a bottom plate, and the bottom plate is connected with two ends of the open lining support to form a closed structure. Preferably, the cross section of the open lining support in this embodiment is arched or "n" shaped, and the arched lining support is used as an example for illustration below.

[0081] The open lining support structure in this embodiment includes several steel pipes arranged uniformly in the longitudinal direction, the first connecting steel plate and the second connecting steel plate connecting adjacent steel pipes; and

[0082] Concrete poured in a plurality of steel pipes and in a space surrounded by adjacent steel pipes, first connecting steel plates and second connecting steel plates. Further, a supporting steel pipe for suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com