Integrated high-pressure gas supply system with solar Stirling generator unit

A technology of solar Stirling and Stirling engines, which is applied in the directions of solar thermal power generation, mechanical power generation by solar energy, machines/engines, etc. It can solve the problems of larger structural size, heavy weight, and bulky unit volume of other equipment, and achieve Low probability of air leakage and failure, few parts and good maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

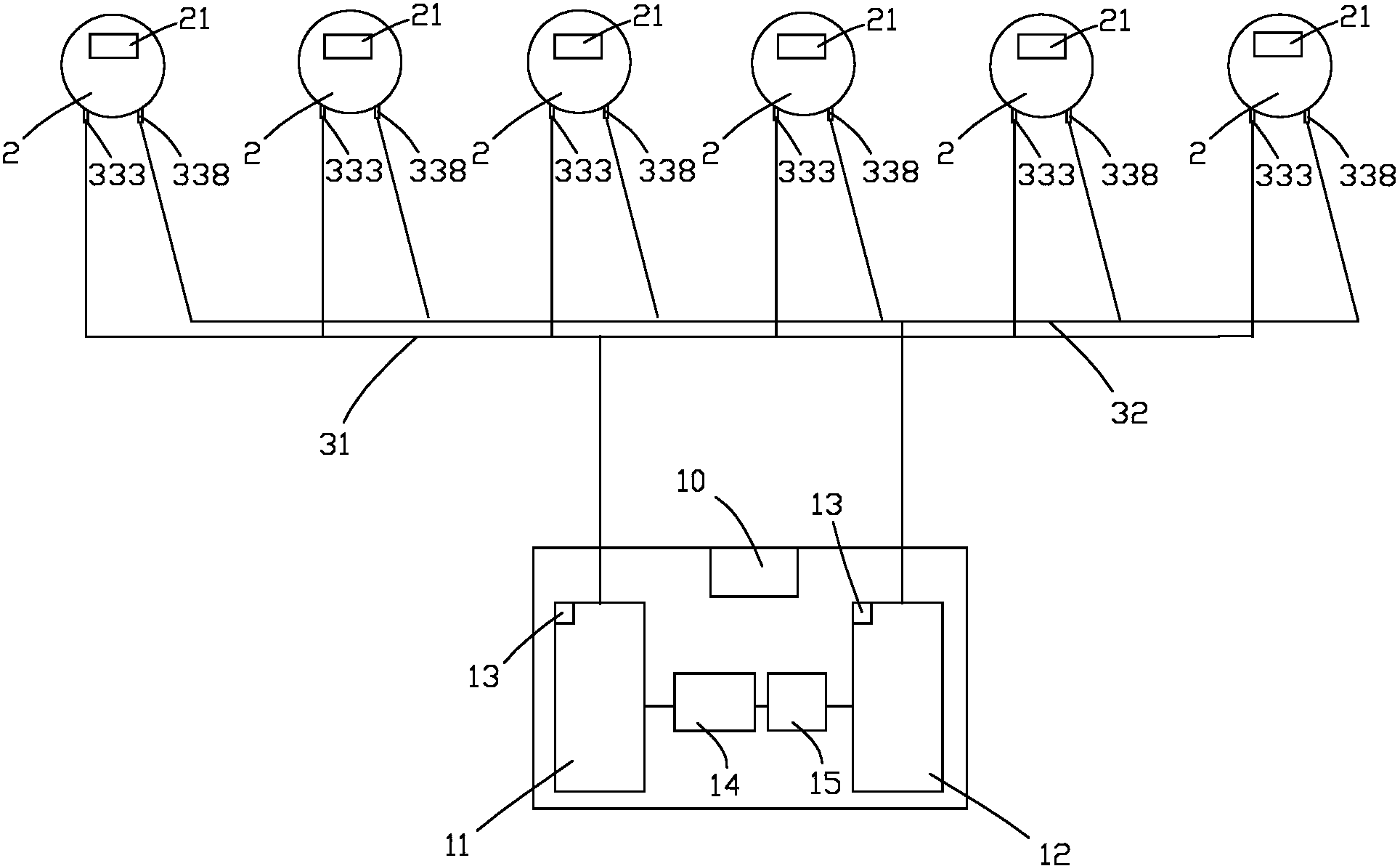

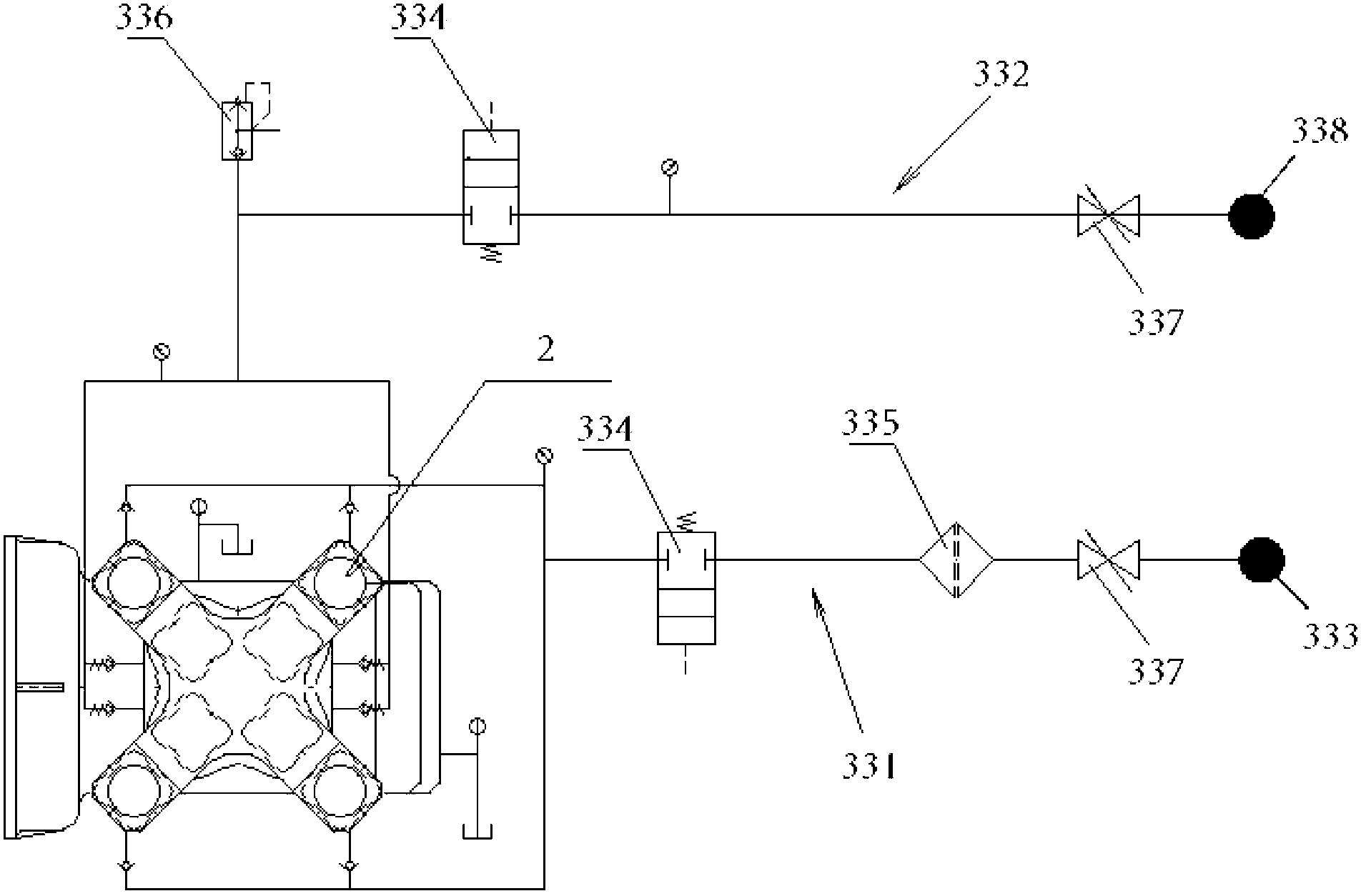

[0027] Such as Figure 1-Figure 2 Shown:

[0028] An integrated high-pressure gas supply system for solar Stirling generator sets, mainly including: an integrated gas supply system; multiple Stirling engines 2 that convert solar energy into electrical energy and connect the integrated gas supply system and each Stirling engine 2 air supply lines.

[0029] As a preferred embodiment, the gas supply pipeline is mainly divided into: delivering the gas stored in the integrated gas supply system to the gas supply main gas circuit 31 of each Stirling engine 2; 2 The high-pressure gas in the working chamber is sent back to the return air main gas path 32 in the integrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com