Lighting device

A technology for lighting devices and transparent substrates, applied in lighting devices, lighting and heating equipment, light guides of lighting systems, etc., can solve problems such as crashing and slow printing speed, and achieve improved printing speed, consistent distribution, and reduced printing data volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

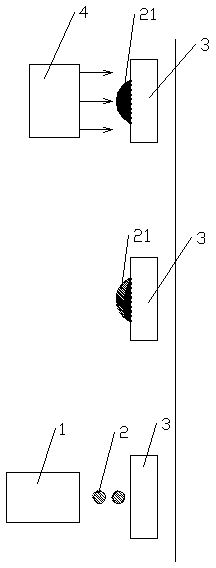

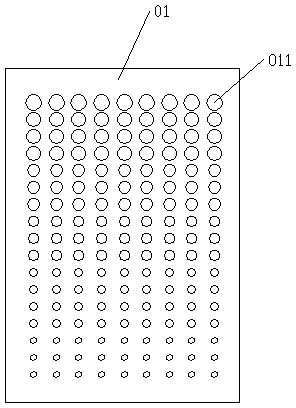

[0031] The lighting device of the present invention includes a light source, a light guide plate, a reflector and a frame, such as figure 2 As shown, the light guide plate of the present invention includes a transparent substrate 01 and a plurality of diffused dots 011, wherein the diffused dots 011 are formed by spraying white or colored ink droplets on the transparent substrate 01 by an inkjet printer and cured by a UV lamp.

[0032] Such as Figure 5 As shown, the manufacturing method of the light guide plate in the lighting device of the present invention includes, step 001) providing a transparent substrate; for receiving ink droplets ejected from the nozzles in the inkjet printing device; step 002) generating through the gradient tool A monochrome gradient image whose size is consistent with the size of the light guide plate to be printed; step 003) import the monochrome gradient image into the printing software; step 004) set the parameter values of dot shape, dot an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com