A test mold capable of realizing constant temperature at the bottom of the rutting specimen

A technology of trial mold and bottom mold, which is applied in the field of constant temperature design at the bottom of rutting specimens, can solve the problems of difficult to ensure uniform support of temperature, and achieve the effect of simple structure, low cost and convenient manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

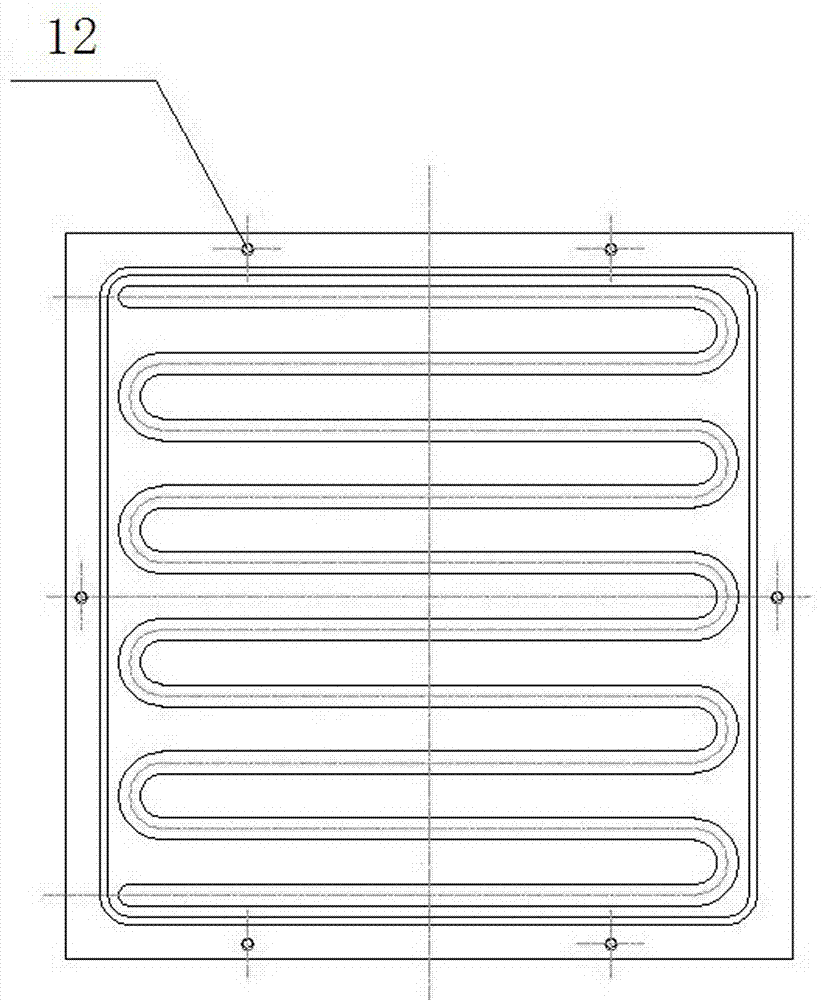

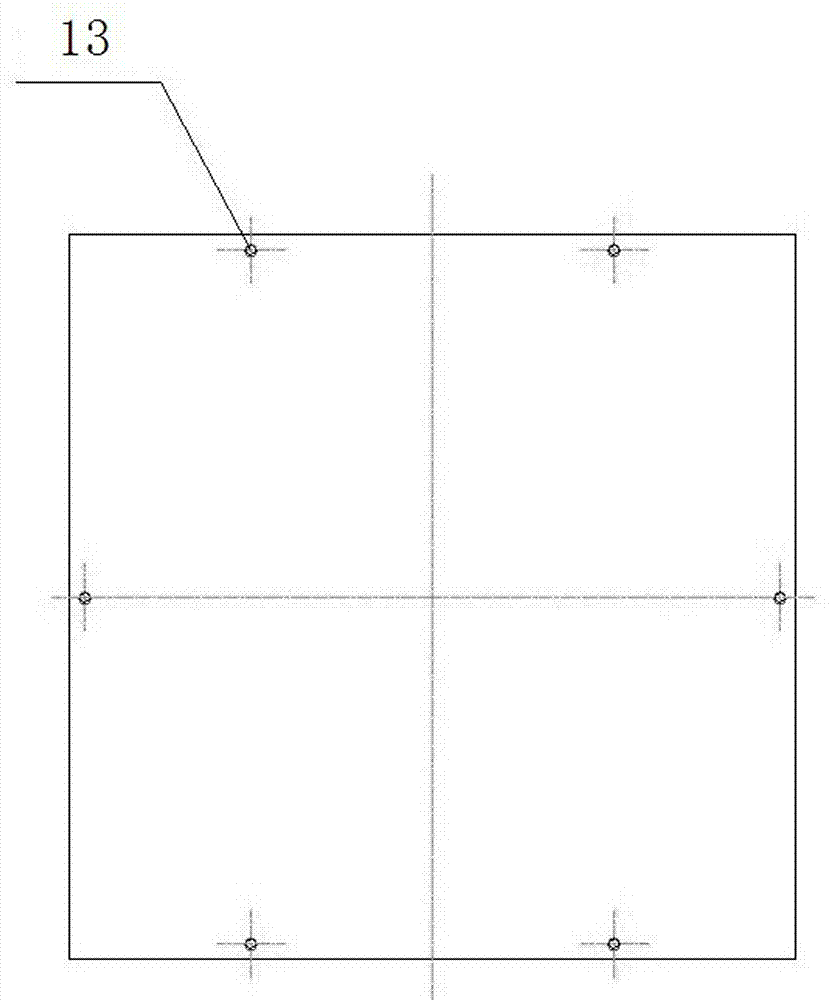

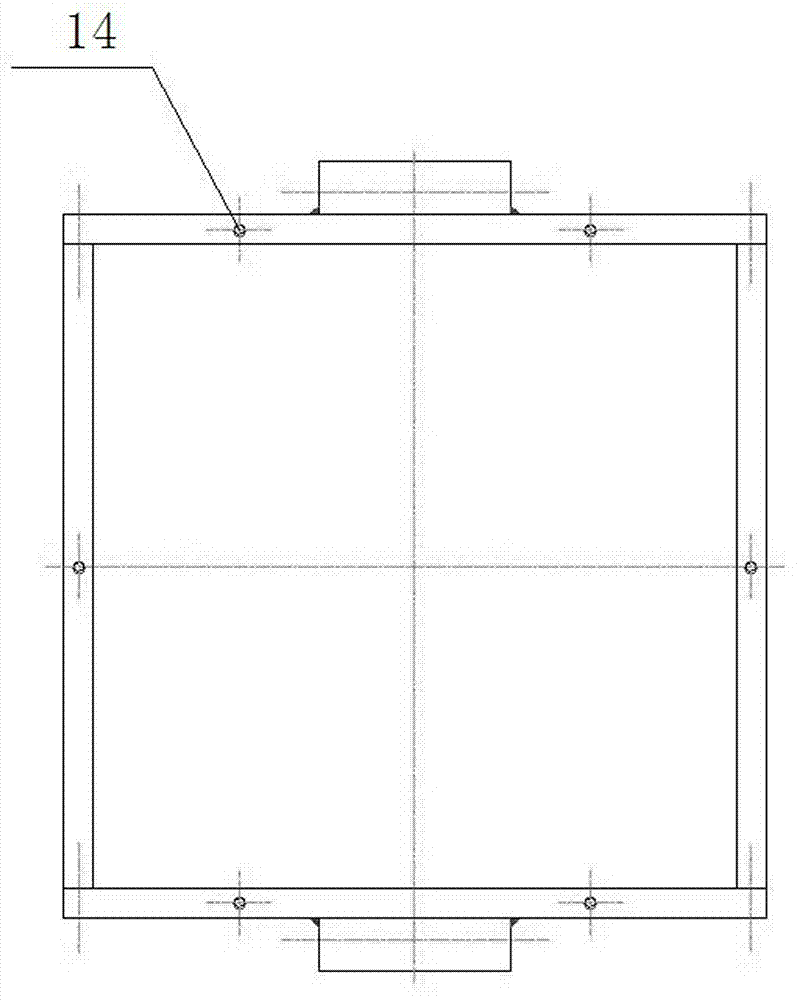

[0042] A test mold capable of realizing constant temperature at the bottom of a rutting specimen, comprising a temperature-controlled bottom mold, a sealing cover plate, and a test mold side plate, from bottom to top, the temperature-controlled bottom mold, a sealing cover plate, and a test mold side plate;

[0043] The temperature control bottom mold is composed of steel plates, sealing rings, constant temperature water channels, fixed holes, water outlets, water outlet pipes, constant temperature equipment, water inlet pipes, and water inlets; the cross section of the steel plates is a square with a side length slightly greater than 30cm; the constant temperature water channels Located on the steel plate, it forms a water pipeline circuit with the water outlet, water outlet pipe, constant temperature equipment, water inlet pipe, and water inlet; the sealing ring to prevent the constant temperature water from overflowing the temperature control bottom mold is located near the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com