Method for measuring wound rotor type motor rated condition rated condition iron loss

A technology of rated working conditions and measurement methods, which is applied to measurement devices, measurement of electrical variables, measurement of resistance/reactance/impedance, etc., can solve problems such as high accuracy and influence, and achieve the effect of simple measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

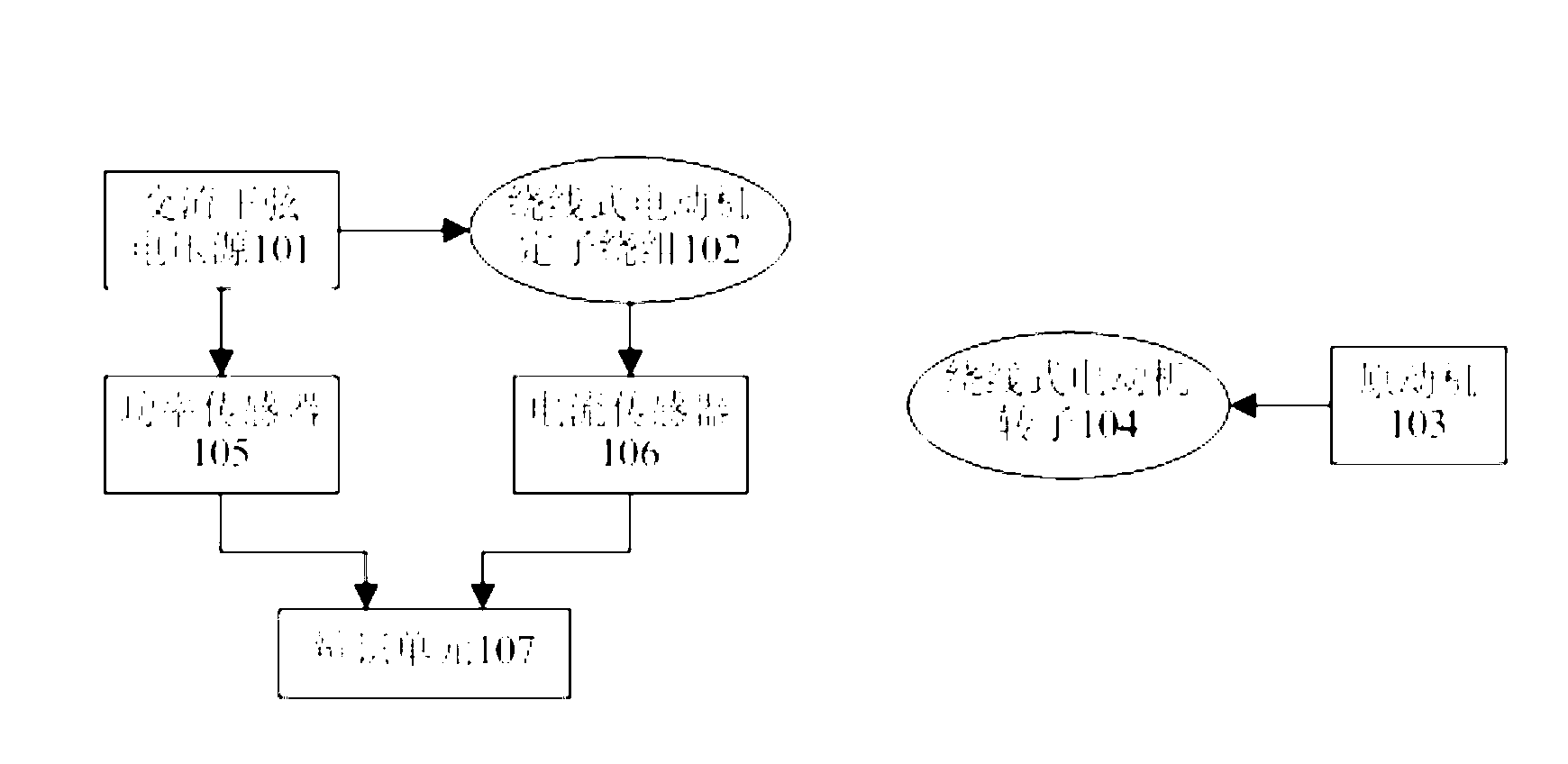

[0017] like figure 1 shown. The iron consumption measuring system of the wound type motor under the rated working condition of the present invention comprises an AC sinusoidal voltage source 101, a wound type motor stator winding 102, a prime mover 103, a wound type motor rotor 104, a power sensor 105, a current sensor 106, and an identification unit 107, wherein the output terminal of the AC sinusoidal voltage source 101 is respectively connected to the input terminal of the stator winding 102 of the wound motor and the input terminal of the power sensor 105, and the output terminal of the power sensor 105 is connected to the input terminal of the identification unit 107, and the wound motor The output terminal of the stator winding 102 is connected to the input terminal of the current sensor 106 , the output terminal of the current sensor 106 is connected to the other input terminal of the identification unit 107 , and the output terminal of the prime mover 103 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com