Display substrate and display device

A technology for display substrates and transparent substrates, applied in identification devices, organic semiconductor devices, instruments, etc., can solve the problems of inconsistent threshold voltage shift, TFT stability decline, unfavorable high-resolution development, etc., to achieve high-resolution, area Reduce and increase the effect of display color gamut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

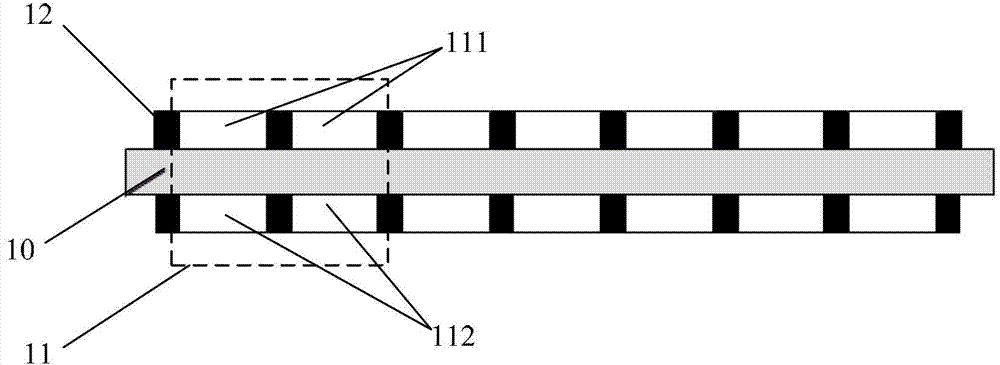

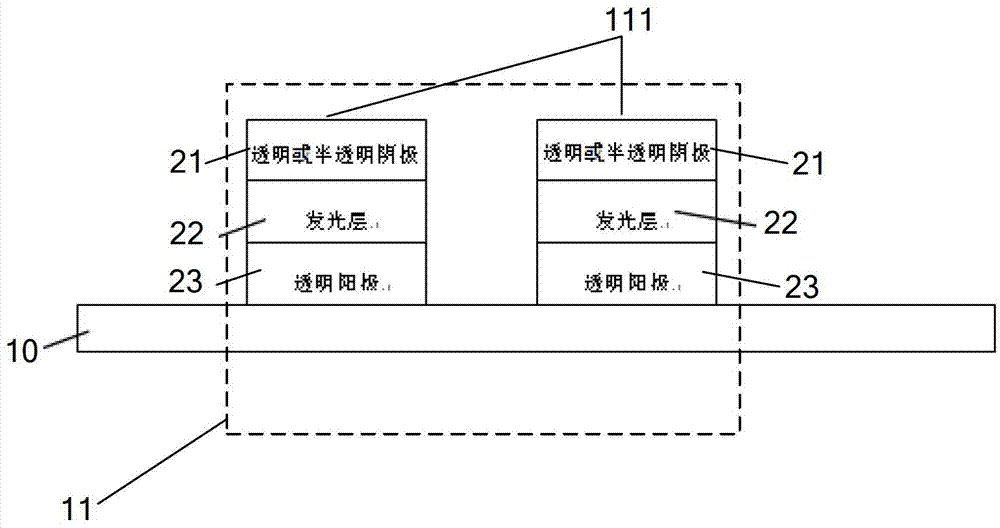

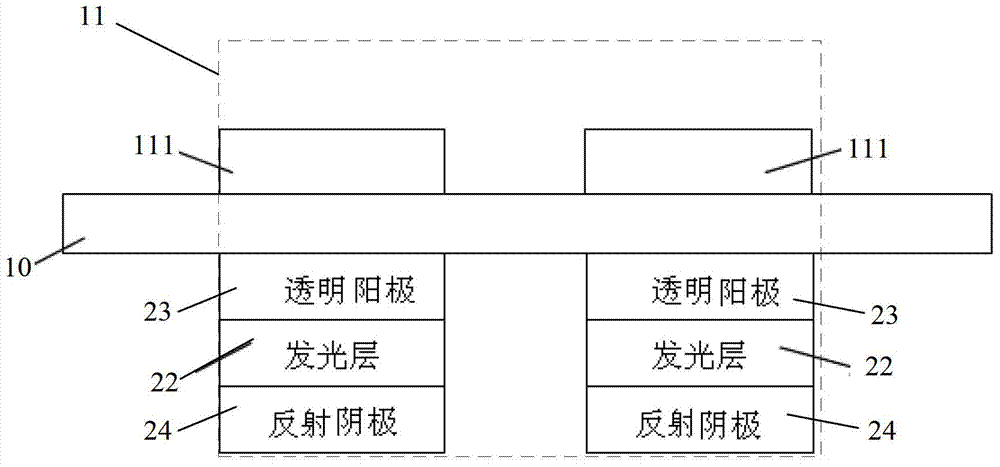

[0037] An embodiment of the present invention provides a display substrate, such as figure 1 As shown, the display substrate includes: a transparent substrate 10, a plurality of display pixels 11 arranged on the transparent substrate 10, each display pixel includes:

[0038] The transparent and self-illuminating first sub-pixel 111 is arranged on the front side of the transparent substrate 10;

[0039] The self-illuminating second sub-pixel 112 is disposed on the back of the transparent substrate 10 , and the light emitting direction of the second sub-pixel 112 includes a direction pointing to the front of the transparent substrate 10 , that is, an upward direction as shown.

[0040] The front side of the transparent substrate 10 described in this embodiment refers to the surface on the side close to the light-emitting surface (viewing surface) of the display substrate, that is, figure 1 The upper surface of the transparent substrate 10 is shown, and the back of the transpare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com