Cable special stripping cutter

A cutting tool and cable technology, which is applied in the direction of dismantling/armouring cable equipment, etc., can solve the problems that the cutting tool cannot be adjusted, fine-tuning cannot be realized, and the manufacturing cost is high, and the effect of simple structure, improved stripping and cutting accuracy, and ingenious conception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

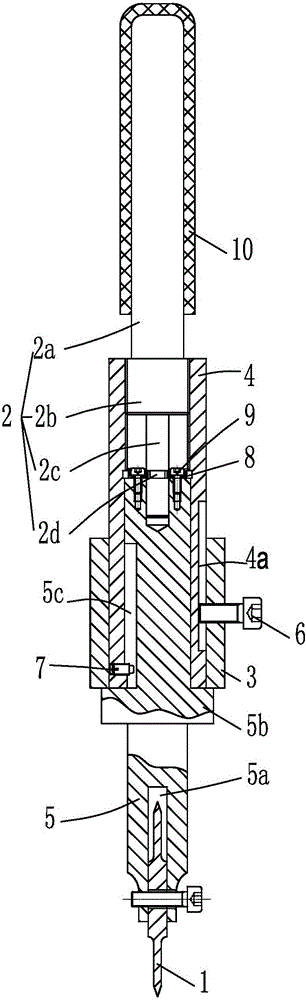

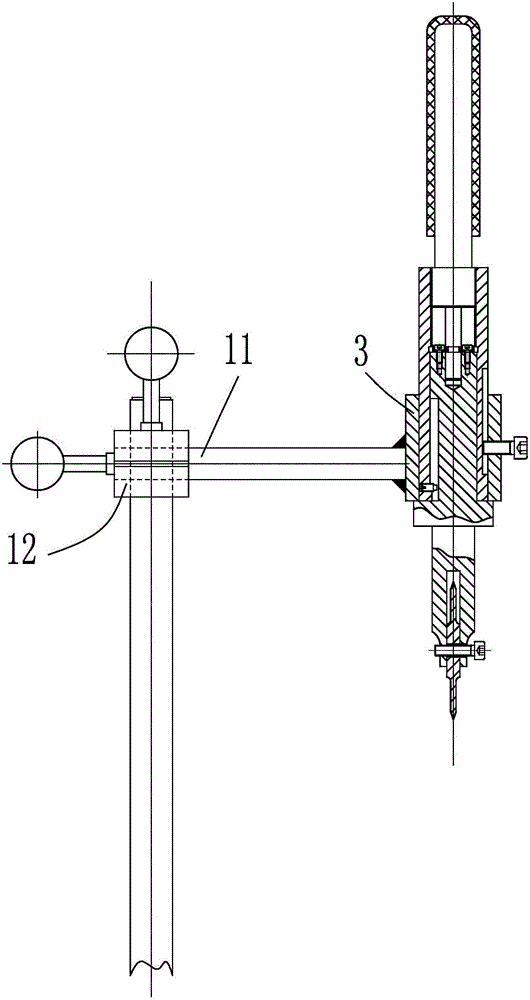

[0013] figure 1 Shown is a special stripping and cutting tool for cables, which is mainly composed of a hob 1, an adjustment rod 2, an outer sleeve 3, a middle sleeve 4, an inner shaft 5, a compression screw 6, and a head screw 7. The inner shaft 5, the middle sleeve 4, and the overcoat 3 are installed coaxially from the inside to the outside, and the adjusting rod 2 and the inner shaft 5 are also installed coaxially, and the adjusting rod 2 is positioned above the inner shaft 5. A gap 5a is formed at the lower end of the inner shaft 5, and the hob 1 is sheathed on the bolt, and is mounted on the inner shaft 5 through the bolt, and the hob 1 is rotatably installed in the gap 5a. The distance from the axis of the hob 1 to the bottom of the notch 5a is smaller than the radius of the hob 1 to ensure that the blade of the hob 1 is located outside the notch 5a to cut cables...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com