Microporous membrane, method for producing same, and battery separator using same

A technology of microporous membranes and manufacturing methods, which can be applied to battery pack parts, transportation fuel cell technology, power system fuel cells, etc., can solve the problems of membrane property degradation and molecular weight degradation, and achieve low shutdown temperature and high safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0143] (1) Preparation of a mixture of polymer and film-making solvent

[0144] The mixture of polymer and film-making solvent was prepared by mixing liquid paraffin with a blend of PMP1, PP1, PE1, PE2. The polymer blend uses: (a) 20wt% polymethylpentene PMP1 (Mitsui Chemicals TPX MX002) (its MFR is 21dg / min, melting point Tm is 222°C); (b) 20wt% Mw is 1.1 ×10 6 , MWD is 8.0, ΔHm is the polypropylene (PP1) of 114J / g; (c) 30wt% Mw is 5.6×10 5 , MWD is 4.05, the amount of unsaturated end groups is 0.14 / 1.0×10 4 Carbon atom, melting point Tm is polyethylene (PE1) of 136.0 ℃; (d) Mw of 30.0wt% is 1.9×10 6 , Polyethylene (PE2) with a melting point of 136.0°C. Here, wt% is based on the weight of the mixed polymer.

[0145] (2) Manufacture of film

[0146] The mixture of polymer and film-forming solvent is fed into the extruder and extruded as a sheet-like extrudate from a sheet-forming die. The mold temperature was 210°C. The extrudate was cooled with chill rolls at 20°C. T...

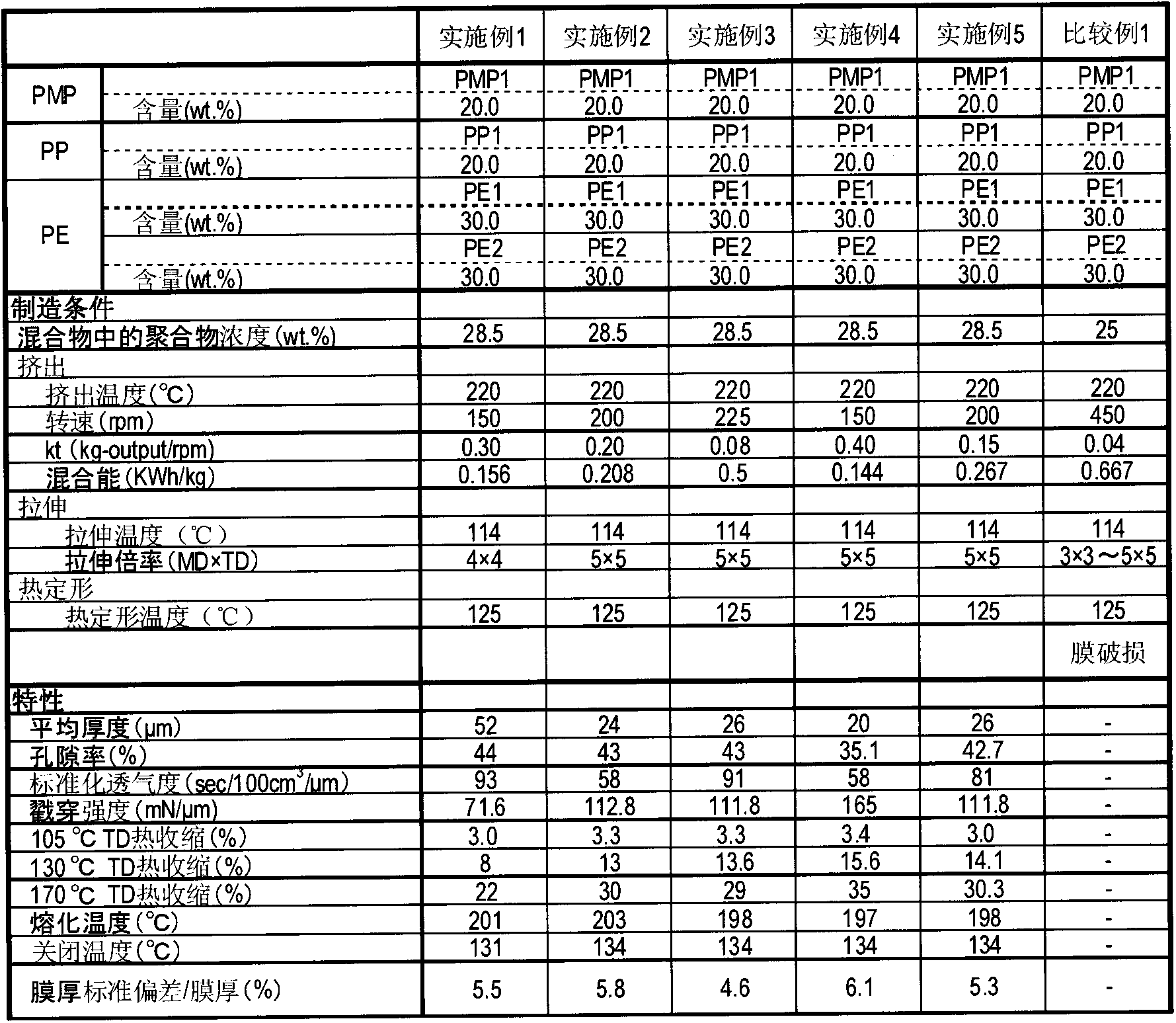

Embodiment 2~5、 comparative example 1

[0148] Except for the items described in Table 1, a microporous membrane was produced in the same manner as in Example 1. The raw materials and process conditions are as described in Table 1.

[0149] [Table 1]

[0150] 【Table 1】

[0151]

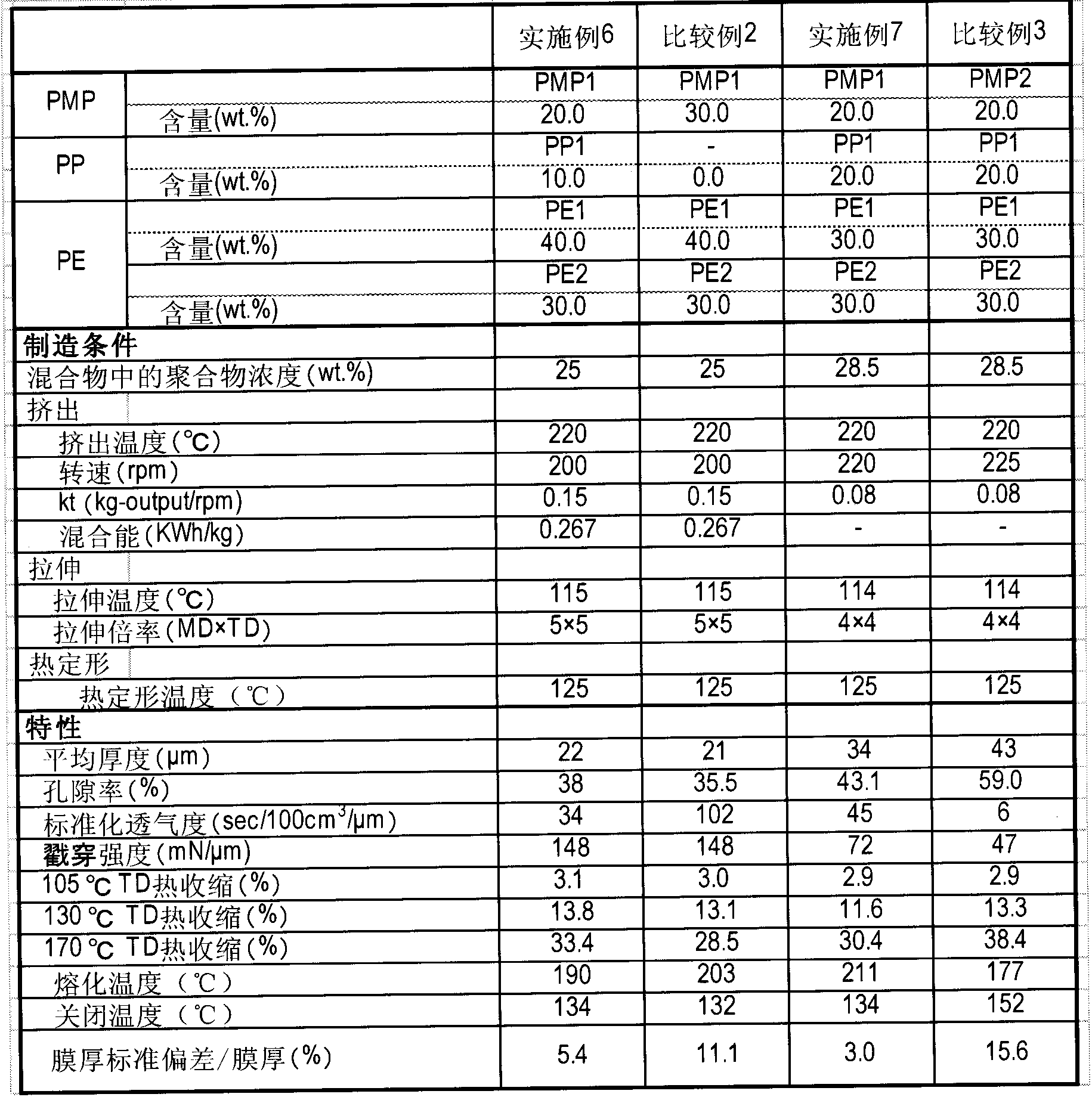

Embodiment 6、7 and comparative example 2、3

[0153]A microporous membrane was produced in the same manner as in Example 1 except that described in Table 2. In addition, in the comparative example, as described in Table 2, the following PMP was used.

[0154] (a) PMP2 (Mitsui Chemicals TPX DX820, MFR=180dg / min, Tm=236°C), PMP3 (Mitsui Chemicals TPX DX310, MFR=100dg / min, Tm=223°C)

[0155] [Table 2]

[0156] 【Table 2】

[0157]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| heat shrinkage ratio | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com