Device for classifying and counting steel balls

A technology of counting device and steel ball, which is applied in solid separation, classification, chemical instruments and methods, etc., can solve the problems of error, inaccurate specifications, long screening time, etc., achieve accurate screening and counting, and is suitable for large-scale use , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

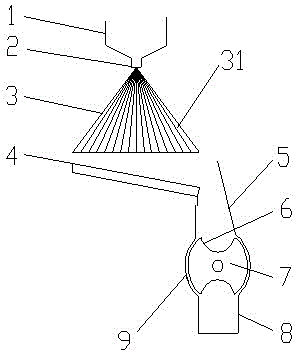

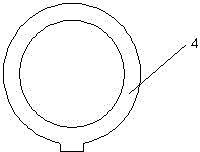

[0012] Such as figure 1 with figure 2 As shown, the steel ball screening and counting device of the present invention includes a groove 1, a steel ball outlet 2 positioned at the bottom of the groove 1, and a steel ball sorter 3 is provided directly below the steel ball outlet 2, and the steel ball sorter 3 is a counting device. A cone formed evenly surrounded by steel bars, the gap between every two adjacent steel bars forms a steel ball sorting slideway 31, and a plurality of adjacent steel ball sorting slideways 31 are arranged directly below the steel ball sorter 3. Sorter 3 concentric ball receiving groove 4, ball receiving groove 4 is circular, and slopes downwards at a certain angle.

[0013] The tube 9 is set under the ball receiving groove 4 where steel balls of required diameter are sorted out, and has two upper and lower openings. The size of the opening is slightly larger than the diameter of the groove. side. The counting wheel 6 is arranged inside the cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com