car seat

A technology for seats and automobiles, which is applied to seat frames, seat suspension devices, etc., can solve the problems of increasing the cost of installation, the complex structure of the vibration damping device, and the high cost of seat production, and achieves simple combined installation and operation. Convenience, simple structure, and the effect of reducing the space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

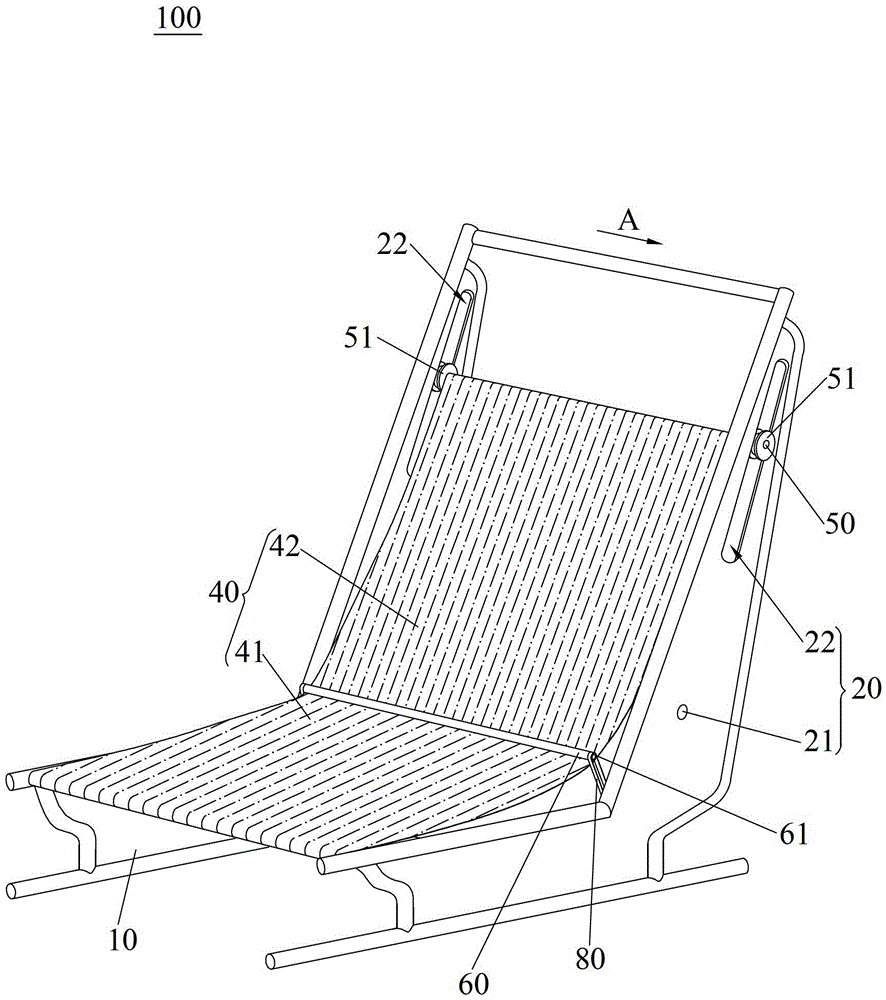

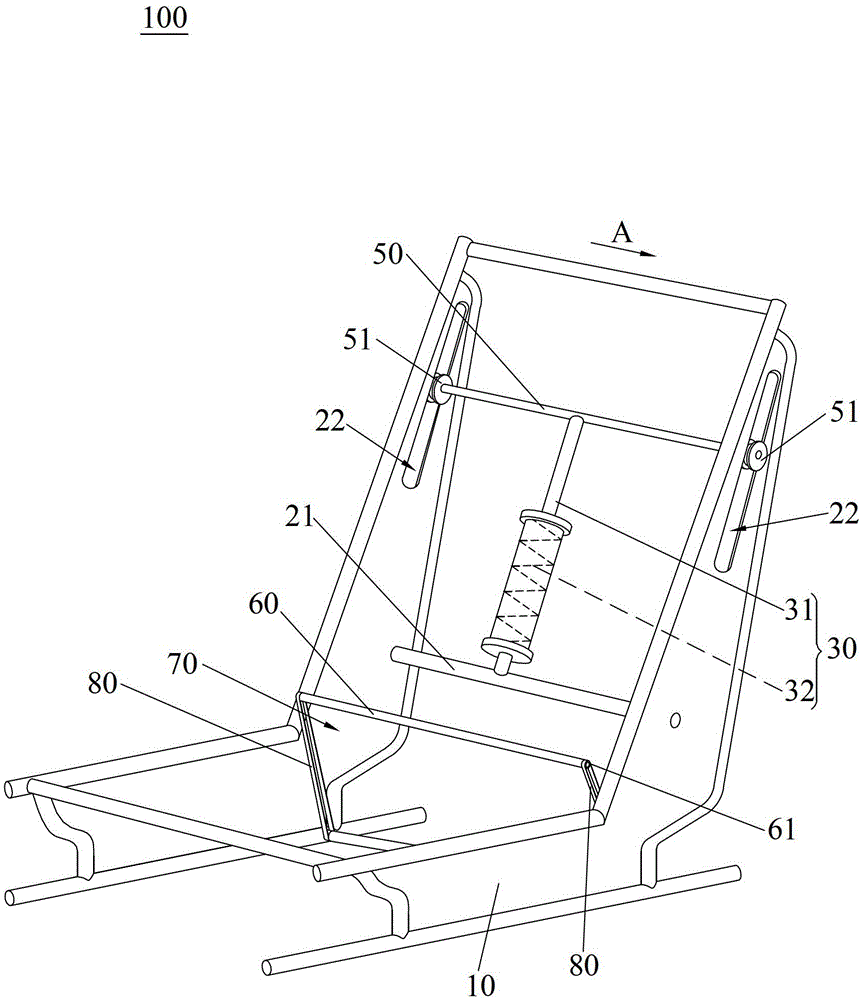

[0019] see Figure 1 to Figure 2 , the automobile vibration-damping seat 100 of the present invention comprises a base frame body 10, a backrest frame body 20 arranged on the base frame body 10, and a sheet-shaped load-bearing connector 40 for a user to ride on. The bottom end of the load-bearing connector 40 Connected on the base frame body 10, wherein, the automobile damping seat 100 of the present invention also includes a shock absorber 30 and a sliding rod 50, the sliding rod 50 is arranged on the backrest frame body 20 that can slide up and down, and slides Rod 50 is transversely on back frame body 20 (that is figure 1 or figure 2 The direction indicated by the middle arrow A or the opposite direction), the top end of the bearing connector 40 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com