Ball guiding device for bearing steel ball

A bearing steel ball and guide ball technology, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of bearing steel ball extrusion, affecting the quality of bearing steel balls, wear and deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

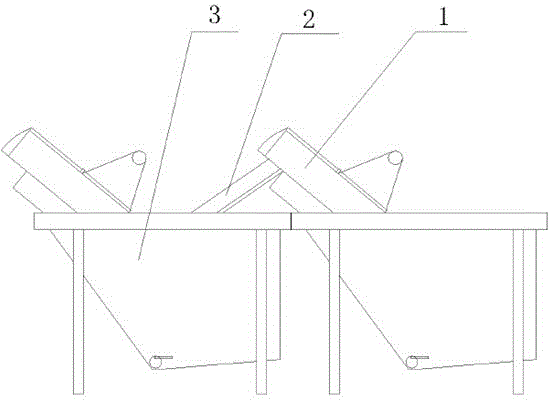

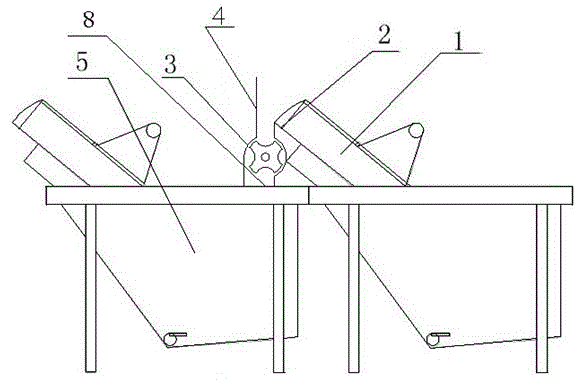

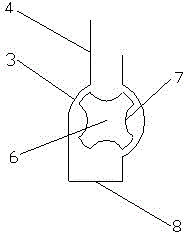

[0015] see figure 2 and image 3 , a ball guide device for bearing steel balls, which includes a conveyor 1, the lower end of the ball outlet 2 of the conveyor 1 is vertically provided with a conveying wheel 3, the conveying wheel 3 is a cylinder placed horizontally, with upper and lower openings, and the interior of the conveying wheel 3 There is a ball guide wheel 6 coaxial with it, and the ball guide wheel 6 is evenly distributed with grooves 7 in the transverse direction. The ball guide wheel 6 is connected to a motor and rotates reversely under the drive of the motor.

[0016] The working process of the ball guide device of the bearing steel ball of the present invention is as follows:

[0017] After the bearing steel ball passes through the conveyor 1, it falls into the conveying wheel 3 from the ball outlet 2. When the groove on the guide wheel 6 turns to the opening of the conveying wheel 3, the bearing steel ball enters the groove and rotates counterclockwise until ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com