Anaerobic membrane bioreactor and forward-osmosis reverse-osmosis combined sewage treatment system

A sewage treatment system, anaerobic membrane biological technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of high ammonia nitrogen concentration, substandard effluent, total nitrogen concentration High problems, to achieve the effect of low process energy consumption, improved processing efficiency, and reduced pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

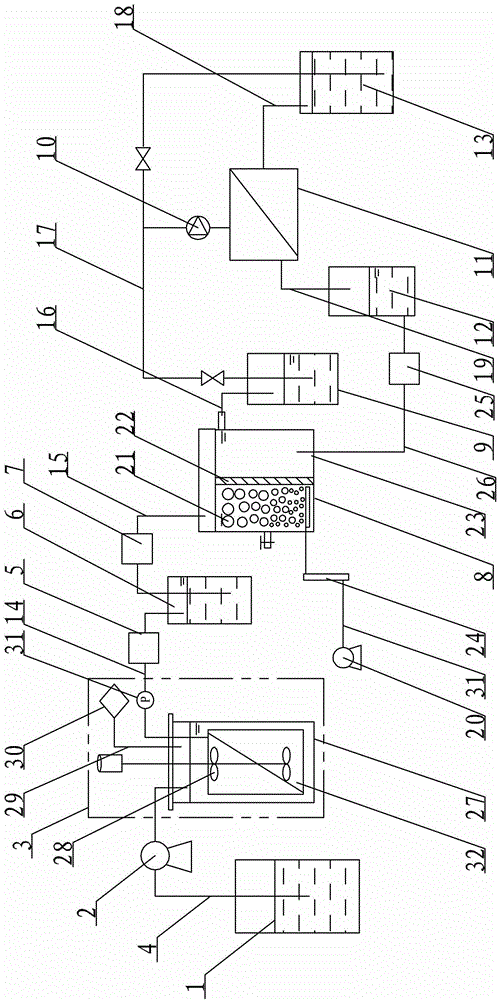

[0018] Specific embodiment one: combination figure 1 To explain this embodiment, this embodiment includes an inlet tank 1, an inlet pump 2, an anaerobic membrane biological reaction module 3, and a first water pipe 4. The inlet tank 1 and the anaerobic membrane biological reaction module 3 are arranged in order from left to right. The water inlet tank 1 and the anaerobic membrane reaction module 3 are connected by a first water pipe 4, and the water inlet pump 2 is arranged on the first water pipe 4. The sewage treatment system also includes an outlet water suction peristaltic pump 5 and a first outlet water storage liquid Box 6, water inlet peristaltic pump 7, forward osmosis component 8, second water outlet tank 9, booster pump 10, reverse osmosis component 11, high concentration sodium chloride drainage tank 12, pure water drainage tank 13, second water pipe 14. The third water pipe 15, the fourth water pipe 16, the three-way water pipe 17, the fifth water pipe 18 and the si...

specific Embodiment approach 2

[0026] Specific implementation manner two: combination figure 1 To illustrate this embodiment, the forward osmosis component 8 of this embodiment includes an aeration pump 20, a forward osmosis biological reaction tank 21, a forward osmosis flat membrane 22, a forward osmosis driving liquid tank 23, and an aeration pipe 31. The forward osmosis flat membrane 22 is vertical. It is directly arranged between the forward osmosis biological reaction tank 21 and the forward osmosis driving liquid tank 23, and the aeration pump 20 is connected to the forward osmosis biological reaction tank 21 through the aeration pipe 31. With this arrangement, the organic matter, ammonia nitrogen, total nitrogen and phosphorus in the effluent of the anaerobic membrane bioreactor are removed by the activated sludge in the forward osmosis biological reaction tank, and these pollutants are also intercepted by the forward osmosis membrane and driven The driving liquid in the liquid pool drives the permea...

specific Embodiment approach 3

[0031] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the forward osmosis component 8 of this embodiment further includes a gas flow meter 24, which is arranged on the aeration pipe 31 between the aeration pump 20 and the outer wall of the forward osmosis biological reaction tank 21. Such a setting is convenient to control the aeration gas flow rate to maintain the amount of dissolved oxygen in the forward osmosis biological reaction tank 21. The other composition and connection relationship are the same as in the second embodiment.

[0032] Specific implementation manner 4: Combination figure 1 To illustrate this embodiment, the sewage treatment system of this embodiment also includes a driving fluid peristaltic pump 25 and a circulating water passage pipe 26. The forward osmosis driving fluid pool 23 and the high-concentration sodium chloride drainage tank 12 pass through the circulating water passage pipe. 26 is connected, the driving...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com