Buckling restrained soft steel energy dissipation wall

An energy-dissipating wall and anti-buckling technology, which is applied in the direction of walls, earthquake resistance, and building components, can solve problems affecting energy dissipation capacity, hysteretic curve pinching, and steel plate surface buckling, so as to suppress out-of-plane buckling, improve ductility, Effect of increasing out-of-plane stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

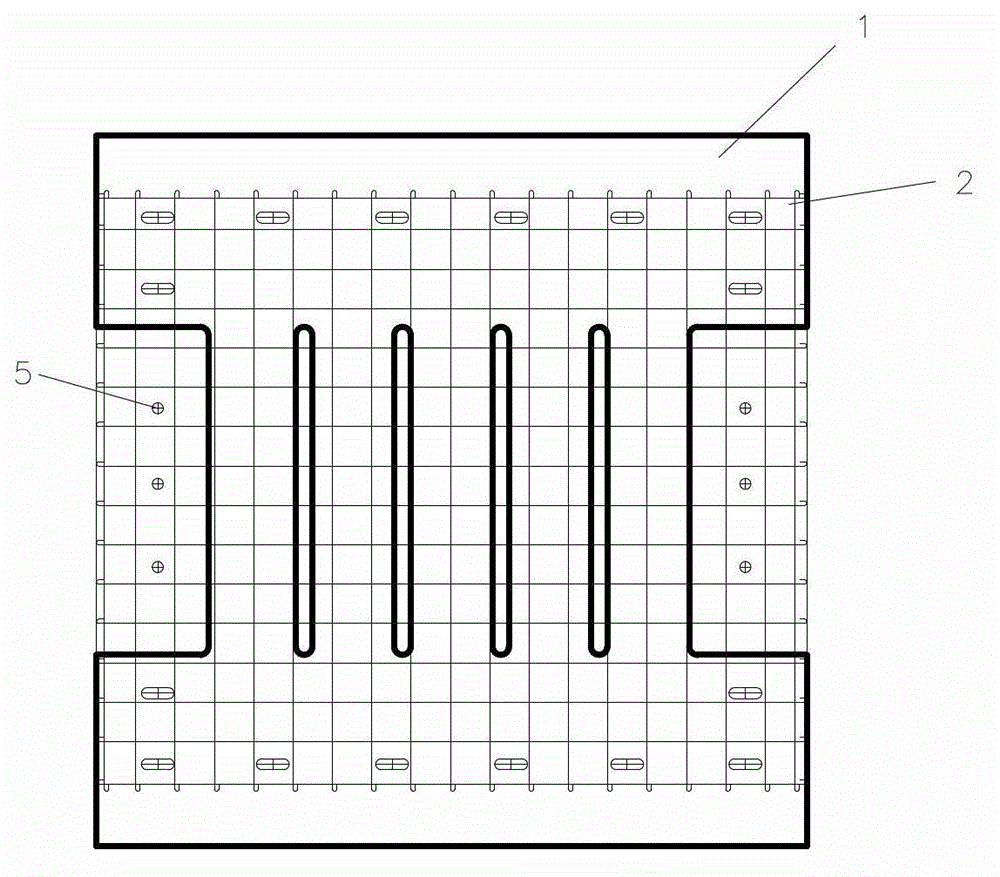

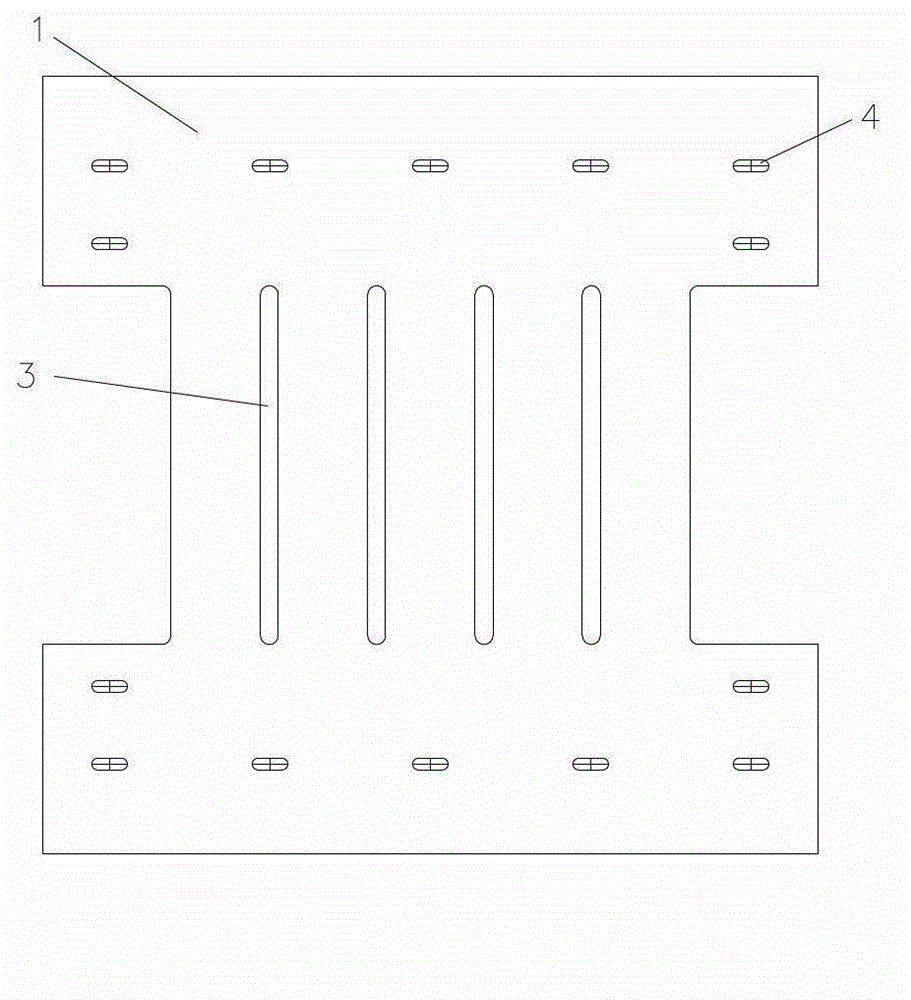

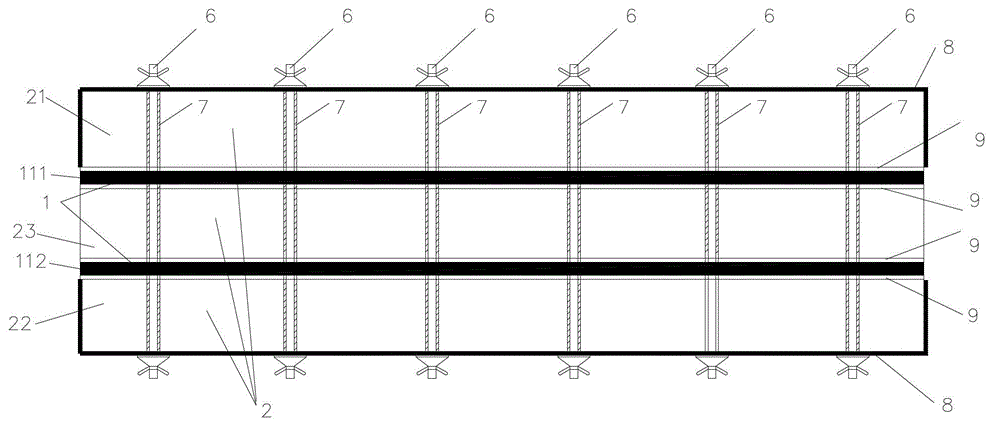

[0023] The anti-buckling mild steel energy-dissipating wall provided by the present invention includes a first steel plate wall 111 and a second steel plate wall 112 arranged in parallel, a prefabricated concrete wall 2 , tension bolts 6 , steel jacket plates 8 and polytetrafluoroethylene plates 9 .

[0024] Both the first steel plate wall 111 and the second steel plate wall 112 are made of mild steel, and the prefabricated concrete wall 2, the steel plate wall 1 and the prefabricated concrete wall are respectively arranged between the first steel plate wall 111 and the second steel plate wall 112 and their respective outer sides 2 between the padded polytetrafluoroethylene plate 9.

[0025] The first prefabricated concrete wall 21 and the second prefabricated concrete wall 22 are arranged outside the first steel plate wall 111 and the second steel plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com