Oil pumping device for oil field rod pumped well

A technology for pumping wells and pumping units, which is applied to wellbore/well components, production fluids, earth-moving drilling, etc., can solve problems such as rising water content of produced fluids, formation pollution drainage cycle, sand production in sandstone oil layers, etc. Achieve the effect of reducing pump efficiency, saving electricity and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

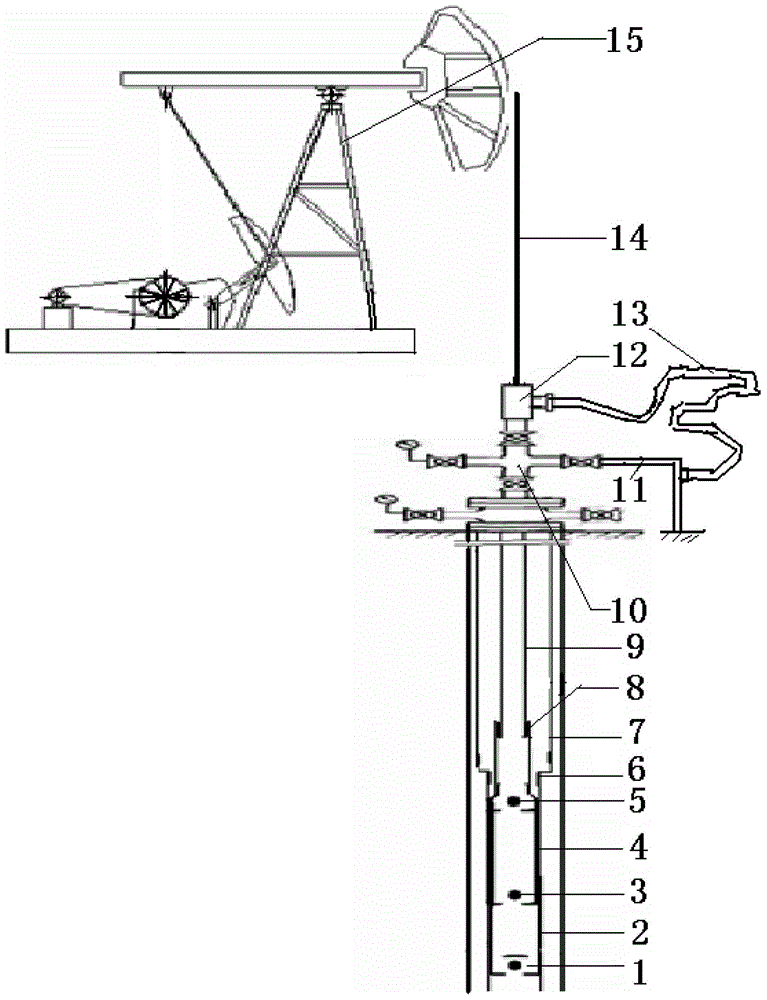

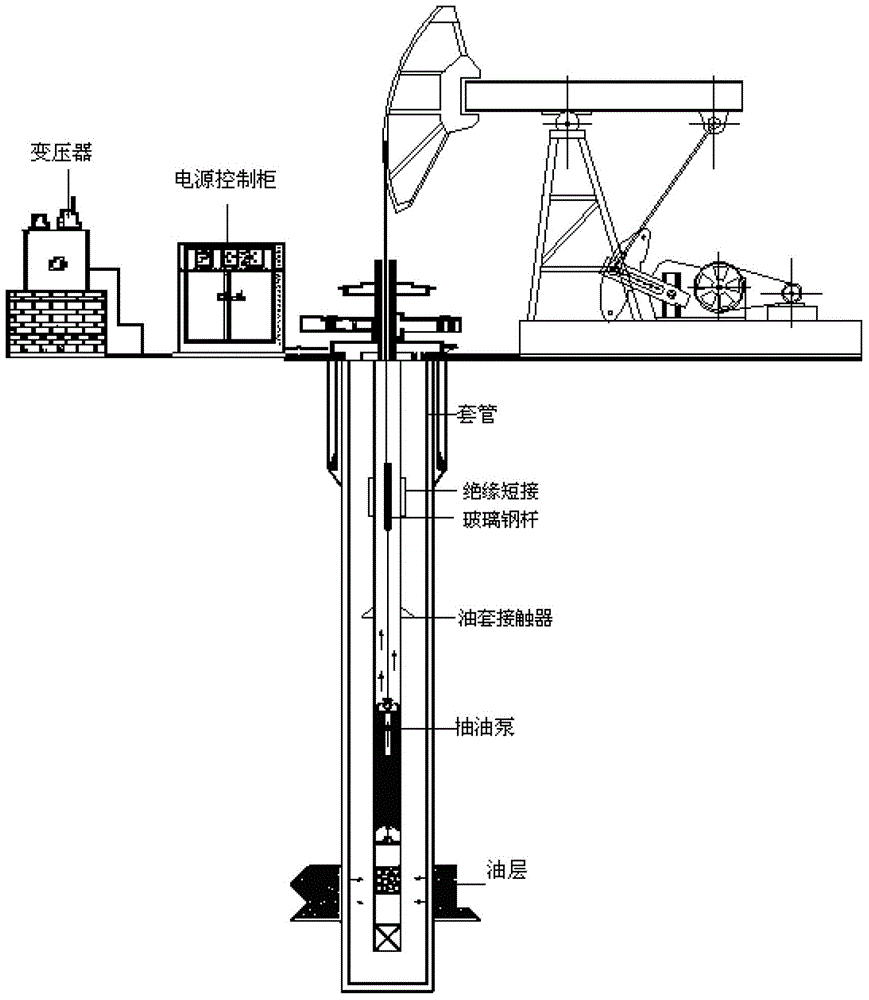

[0026] The oil field pumping unit well pumping device of the present invention will be described with reference to the accompanying drawings.

[0027] Such as figure 1 As shown, in the pumping unit of the oil field pumping unit well of the present invention, the pumping unit 15 is connected to the hollow rod 9 through the polished rod 14 and the three-way short-connection 12 in sequence, and the three-way short-connection 12 is arranged on the bottom of the Christmas tree 10. Above, its side outlet is connected to the oil delivery pipeline 11 through a hose 13; the hollow rod 9 passes through the Christmas tree 10 fixedly installed on the ground, and is connected to the upstream traveling valve 5 of the oil well pump through the hollow rod joint 8 A tubing 7 is connected to the lower end of the Christmas tree 10; the oil well pump is configured to be connected with an upper traveling valve 5, a plunger 4, and a lower traveling valve in the pump cylinder 2 in sequence from top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com