Intelligent diagnosis method for faults of mining drilling machine gearbox

An intelligent diagnosis and gearbox technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problem of difficulty in obtaining typical fault samples of gearboxes, and achieve the effects of improving diagnostic accuracy, accurate diagnosis, and improving computing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

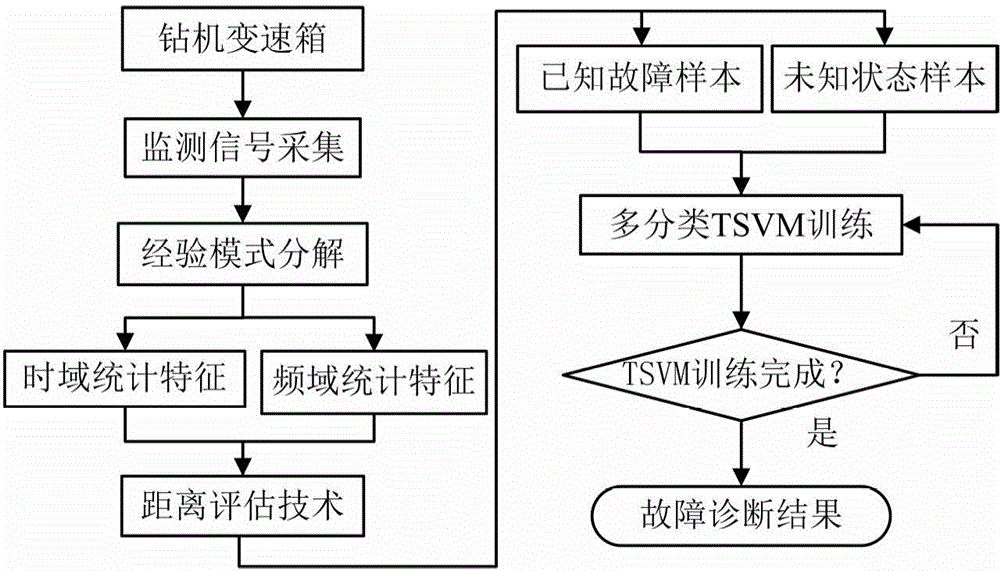

[0032] refer to figure 1 Shown is a frame diagram based on empirical mode decomposition and TSVM intelligent diagnosis, describing the construction process of the model.

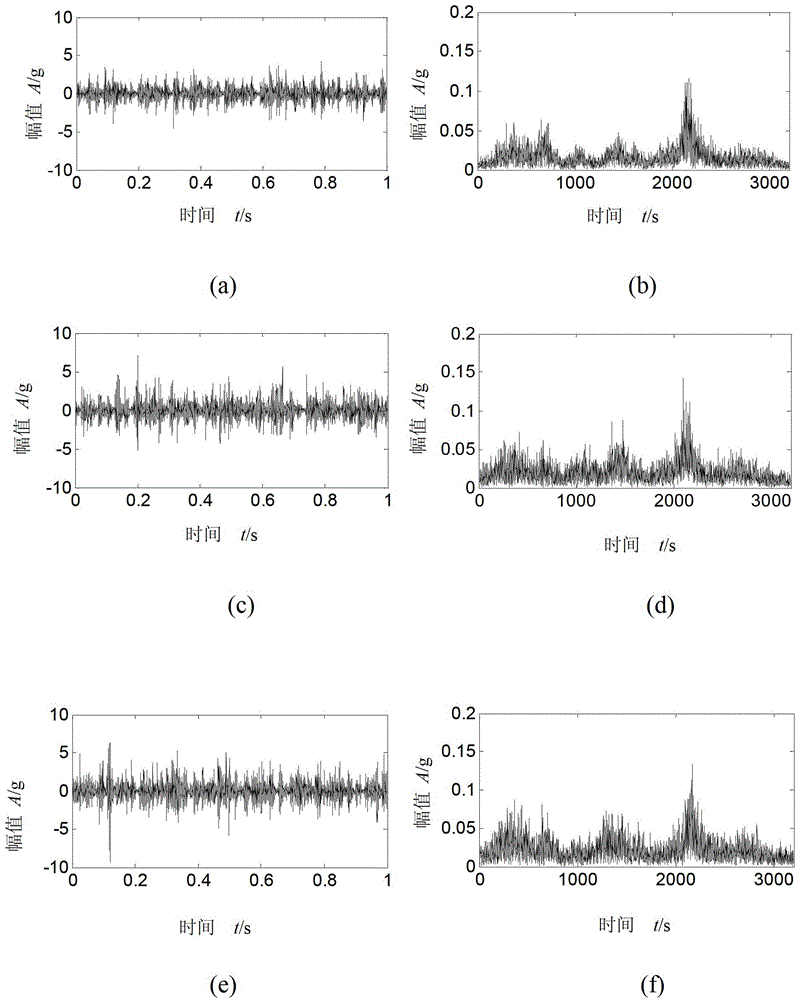

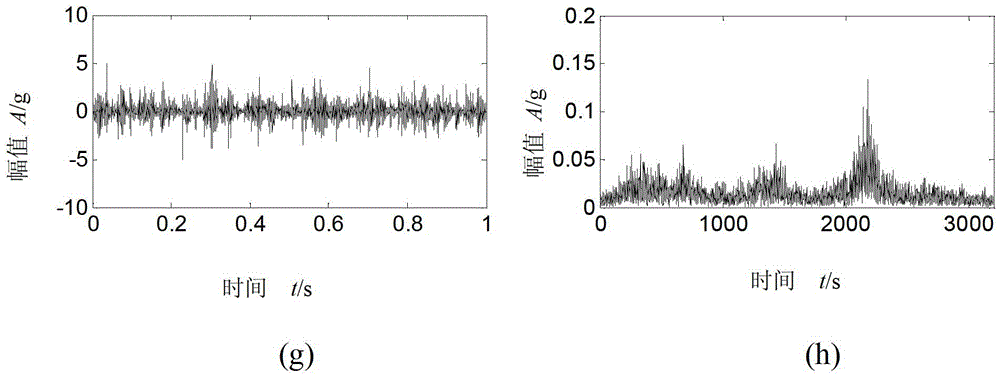

[0033] refer to figure 2 Shown are the time-domain waveforms and spectrograms of the four-state gearbox monitoring signals. (a), (c), (e), and (g) are the time-domain waveforms of the gearbox monitoring signals in four states. It can be seen from the time-domain waveform diagram that there are differences in the monitoring signals of the gearbox in the four states, but the type of gearbox fault cannot be judged based on these differences. (b), (d), (f), and (h) are the spectrum diagrams of monitoring signals of gearboxes in four states. The spectrogram shows that there are differences in the monitoring signals of the gearbox in the four states, but this difference cannot be used to directly judge the type of gearbox fault.

[0034] refer to image 3 Shown is the result of intelligent diagnosis based on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com