Intelligent tool fault diagnosis method

A diagnostic method and fault diagnosis technology, applied in the direction of manufacturing tools, metal processing machinery parts, measuring/indicating equipment, etc., can solve problems that affect production efficiency, consume large labor costs, and consume economic costs, so as to reduce labor costs and adapt to High performance and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0029] The present invention provides a kind of intelligent tool fault diagnosis method, it comprises the following steps:

[0030] 1) Obtain the three-phase current signals generated by the total motor during the machining process of the machine tool: the vibration signal generated by the tool cutting, the cutting force signal and the acoustic emission signal. And analyze and process the various signals collected, and extract the sensitive features of the tool;

[0031] The steps of the extraction method of tool sensitive features are as follows:

[0032] 1.1) Collect the three-phase current signals generated by the total motor in n different wear stages of the tool: the vibration signal generated by the tool cutting, the cutting force signal and the acoustic emission signal.

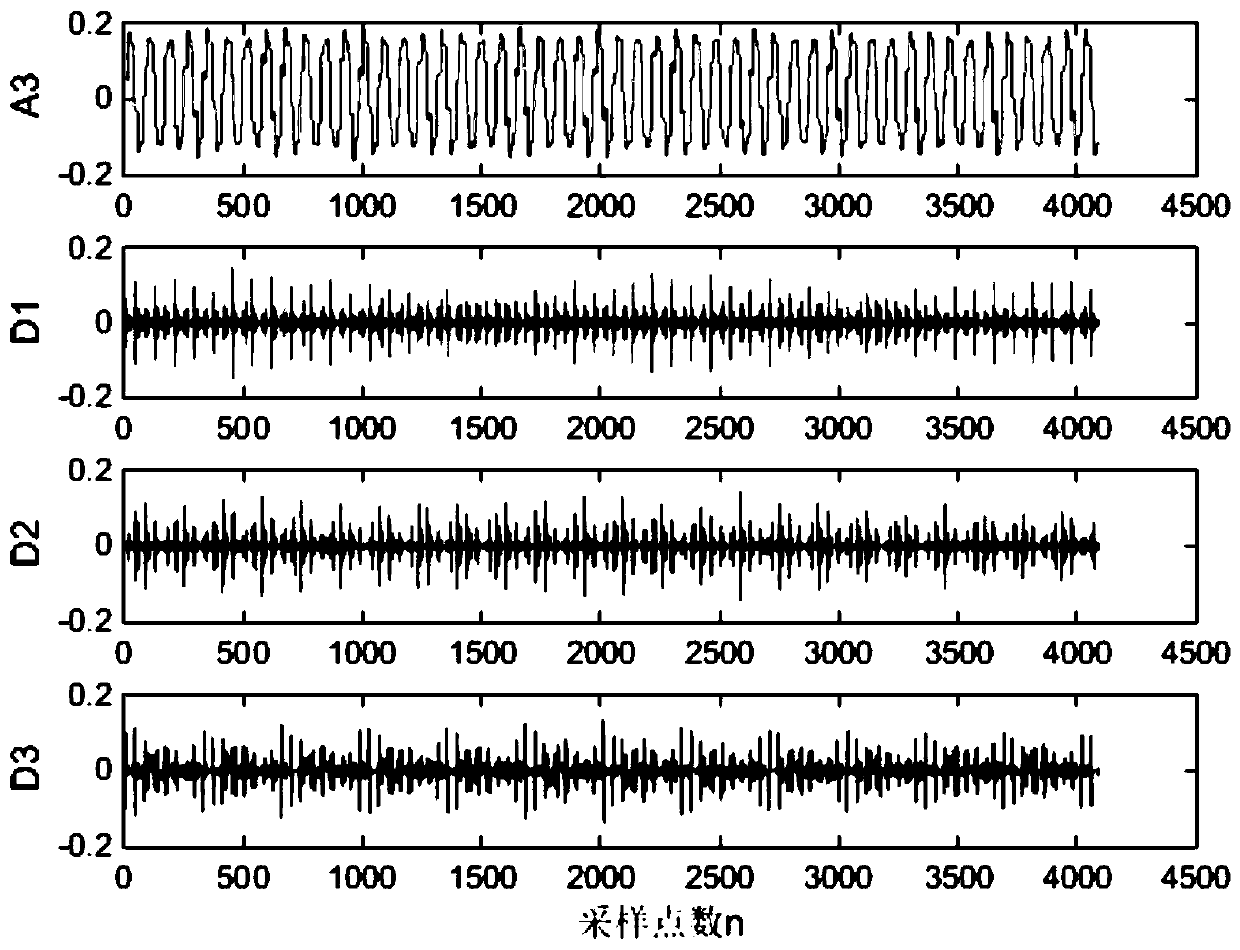

[0033] 1.2) Time-domain analysis is performed on various collected sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com