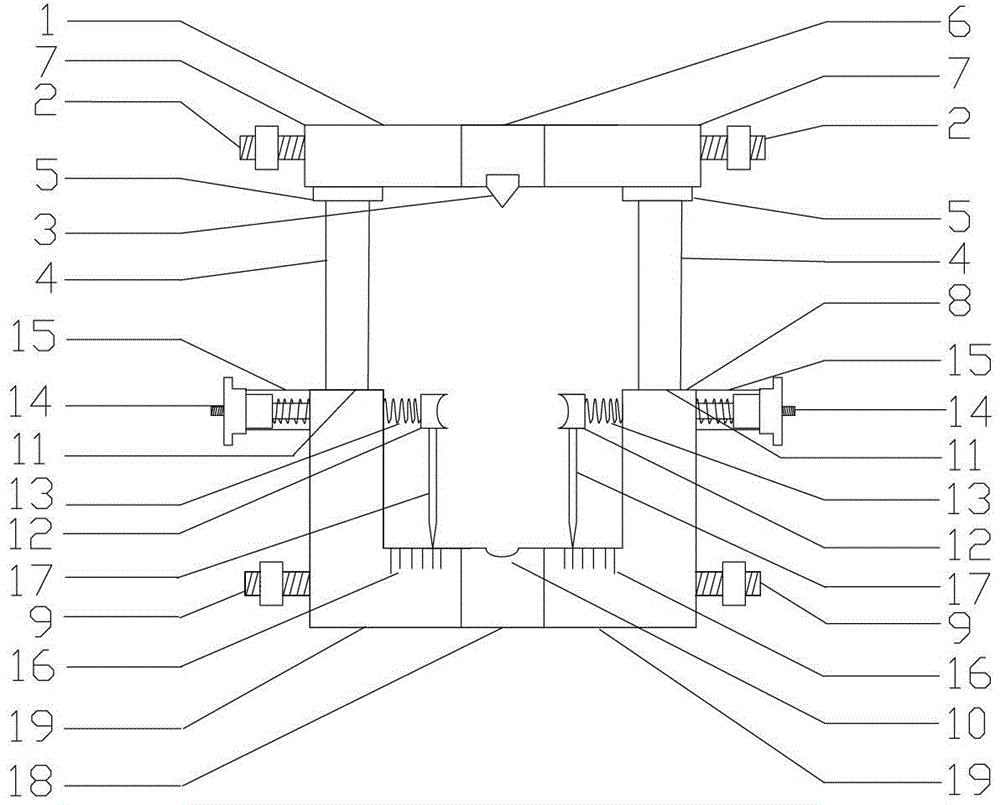

Rock-like material splitting test device

A test device and rock quality technology, which is applied in the direction of using stable tension/pressure to test the strength of materials, etc., can solve the problems of reducing the accuracy and reliability of the results, not seeing the research report of the test device, and erroneous evaluation of structural stability. , to achieve the effect of good test accuracy, flexible operation and reliable principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

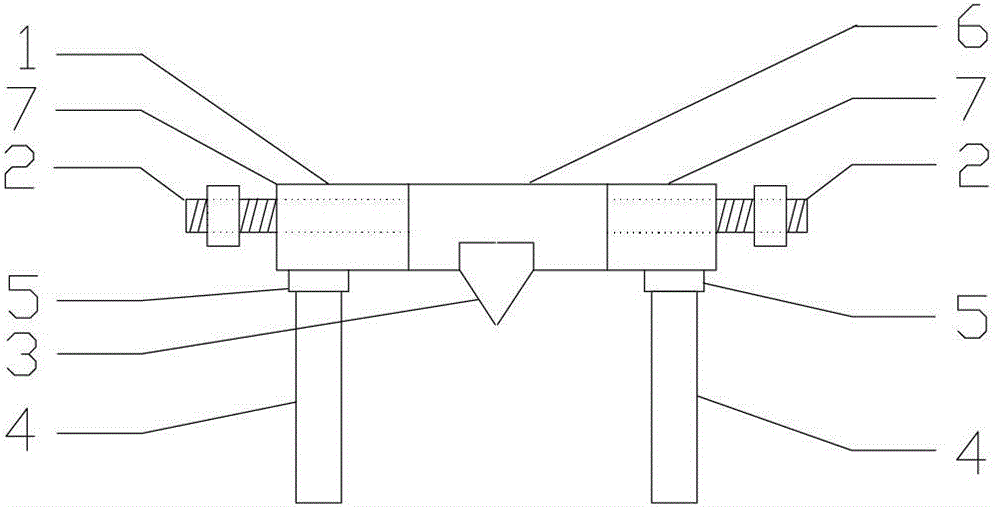

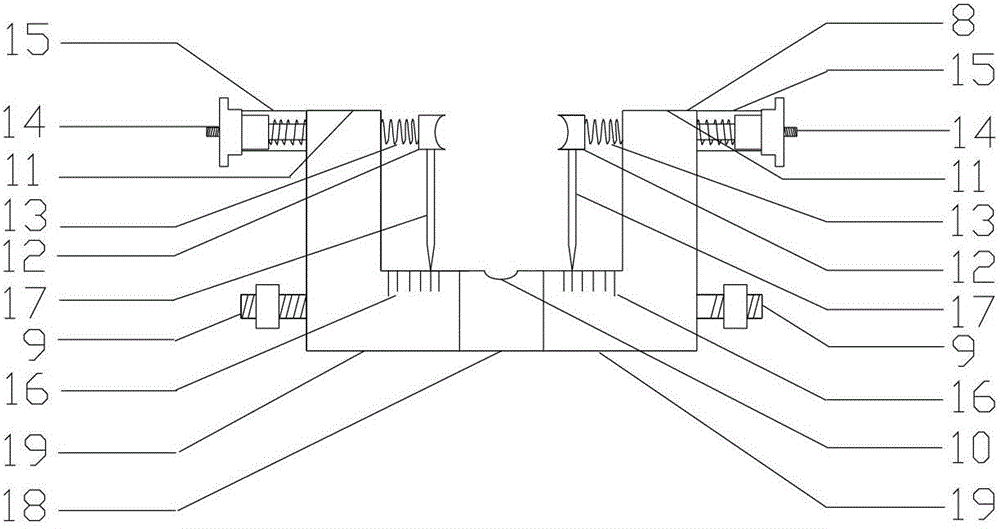

[0013] The main body structure of this embodiment is assembled into an integrated splitting experimental device by the cooperation of two functional structural parts of main body one and main body two; wherein, main body one includes an upper pressing plate 1, an upper adjusting bolt 2, a blade-shaped indenter 3, and a fixing column 4 , upper platen spacer 5, the upper side of the upper platen 1 is in contact with the externally connected hydraulic pressure device, the lower side of the upper platen 1 is in contact with the tested sample and applies pressure to the tested sample; the upper platen 1 is divided into a middle fixed part 6 and The movable parts 7 on both sides; the upper adjustment bolt 2 is fixedly connected with the middle fixed part 6 of the upper pressure plate 1, the upper adjustment bolt 2 is connected in series with the movable parts 7 on both sides of the upper pressure plate 1, and the upper pressure plate is adjusted by the nut at the end of the upper adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com