An analog measurement device and measurement method for static friction coefficient of galvanized steel plate of iron tower

A technology of static friction coefficient and galvanized steel sheet, which is applied to measuring devices, mechanical devices, instruments, etc., can solve the problems of measuring the static friction coefficient and difference of galvanized steel sheet of iron tower, and achieve the effect of strong repeatability and improved accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

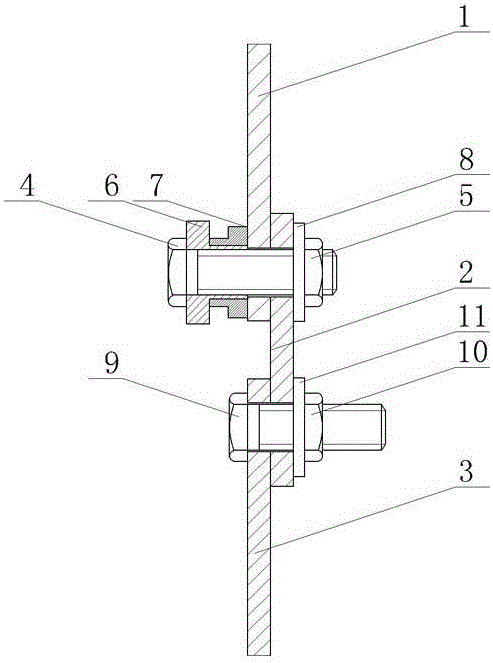

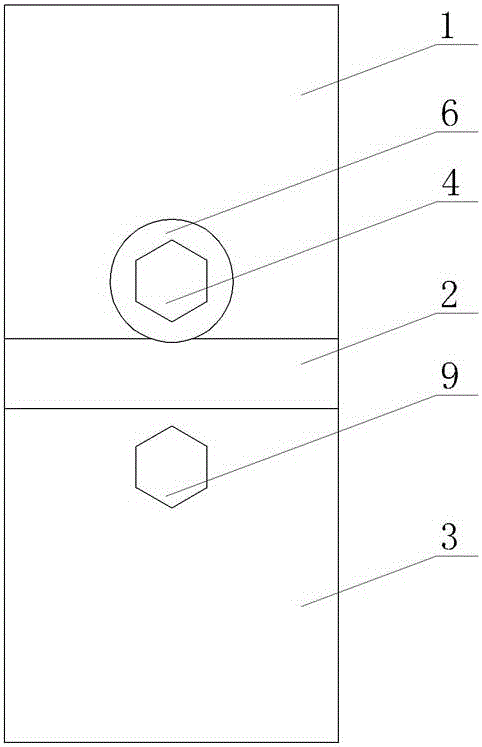

[0055] As attached figure 1 , 2 , The analog measuring device of the present invention is composed of upper galvanized steel sheet 1, middle galvanized steel sheet 2, lower galvanized steel sheet 3, sleeve 6 and pressure sensor 7; on the lower end of the upper galvanized steel sheet 1 and the lower galvanized steel sheet The upper ends of the steel plate 3 are respectively provided with bolt holes with equal diameters, and the upper and lower ends of the middle galvanized dry plate 2 are respectively provided with bolt holes with the same diameter as the bolt holes; the sleeve 6, the pressure sensor 7, The upper ends of the upper galvanized steel sheet 1 and the middle galvanized steel sheet 2 are sequentially connected by a first bolt 4 and a first nut 5; the lower end of the middle galvanized steel sheet 2 and the lower galvanized steel sheet 3 are connected by a second bolt 9 and a second nut 10Connect. A first washer 8 is sleeved on the first bolt 4 between the middle galva...

Embodiment 2

[0057] The difference between Example 2 and Example 1 is that there is no washer between the steel plate and the nut. The test can be stopped when the sliding between the upper galvanized steel sheet 1 and the middle galvanized steel sheet 2 is blocked, so removing the washer does not Affect the accuracy of test data.

Embodiment 3

[0059] The simulation measuring device of Example 1 was used to measure the static friction coefficient of the galvanized steel tower under high contact pressure.

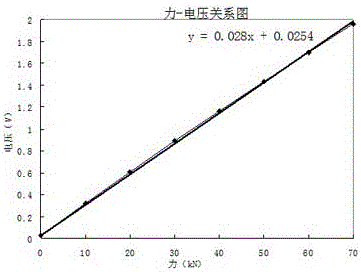

[0060] Step 1: Clamp the upper end of the upper galvanized steel sheet 1 and the lower end of the lower galvanized steel sheet 3 into the upper and lower clamps of the tensile testing machine, respectively, and connect the output cable of the pressure sensor 7 to the tensile test Connect the corresponding input terminals of the machine. The upper galvanized steel sheet 1, the middle galvanized steel sheet 2 and the lower galvanized steel sheet 3 of this embodiment are all galvanized steel sheets with a width of 120mm and a thickness of 10mm. The hole diameter is Ф21.5mm. The punching process is adopted. Zinc. The specifications of the first bolt 4, the first nut 5, the first washer 8, the second bolt 9, the second nut 10, and the second washer 11 in this embodiment are M20, galvanized, and multiple sets. The sensor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com