Hydraulic cylinder inclined iron adjustment device of eighteen rolling mill working roll side supports

A technology of work rolls and side supports, which is applied in the direction of counter pressure devices, metal rolling stands, metal rolling stands, etc., can solve the problems of complex structure of side support devices, inconvenient adjustment and maintenance, and high processing precision requirements, and achieve The effect of reducing manual adjustment time, reducing equipment costs and control costs, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific drawings and embodiments.

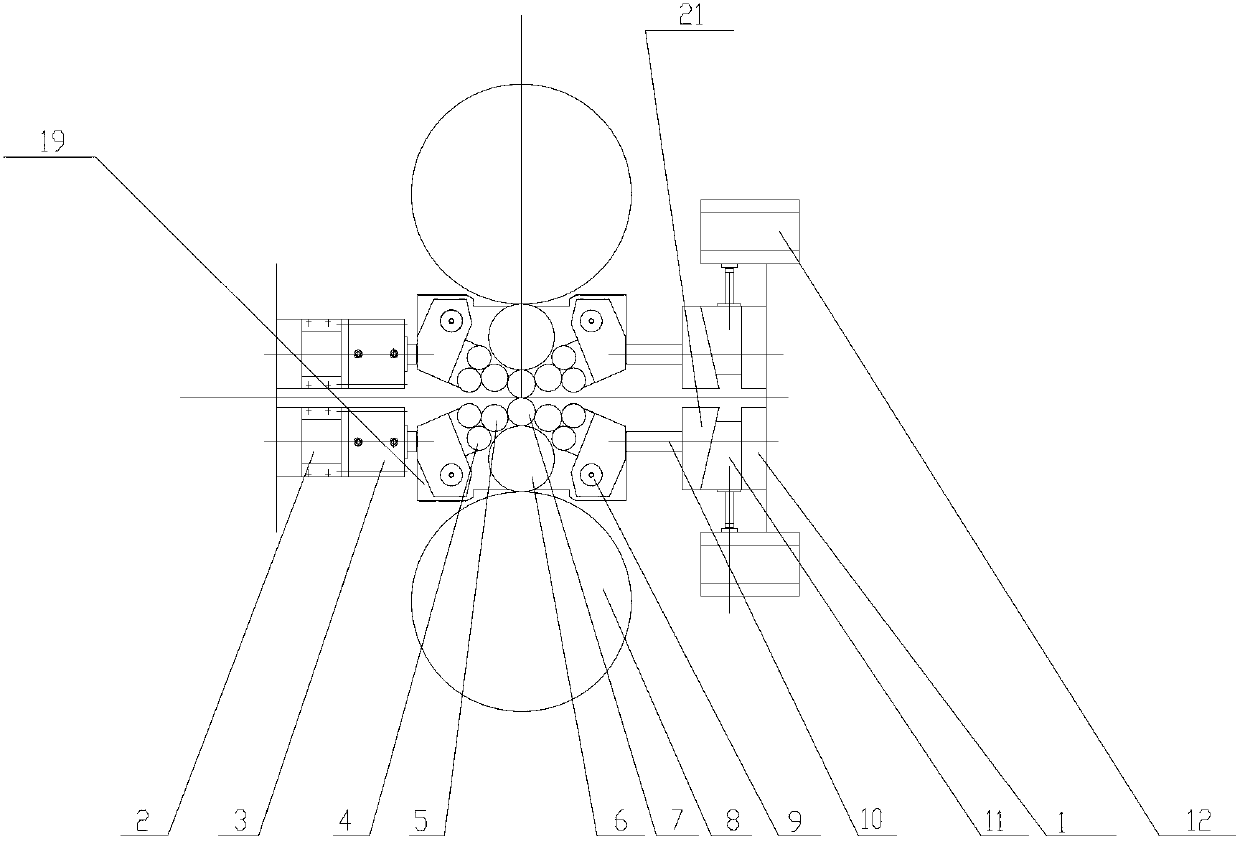

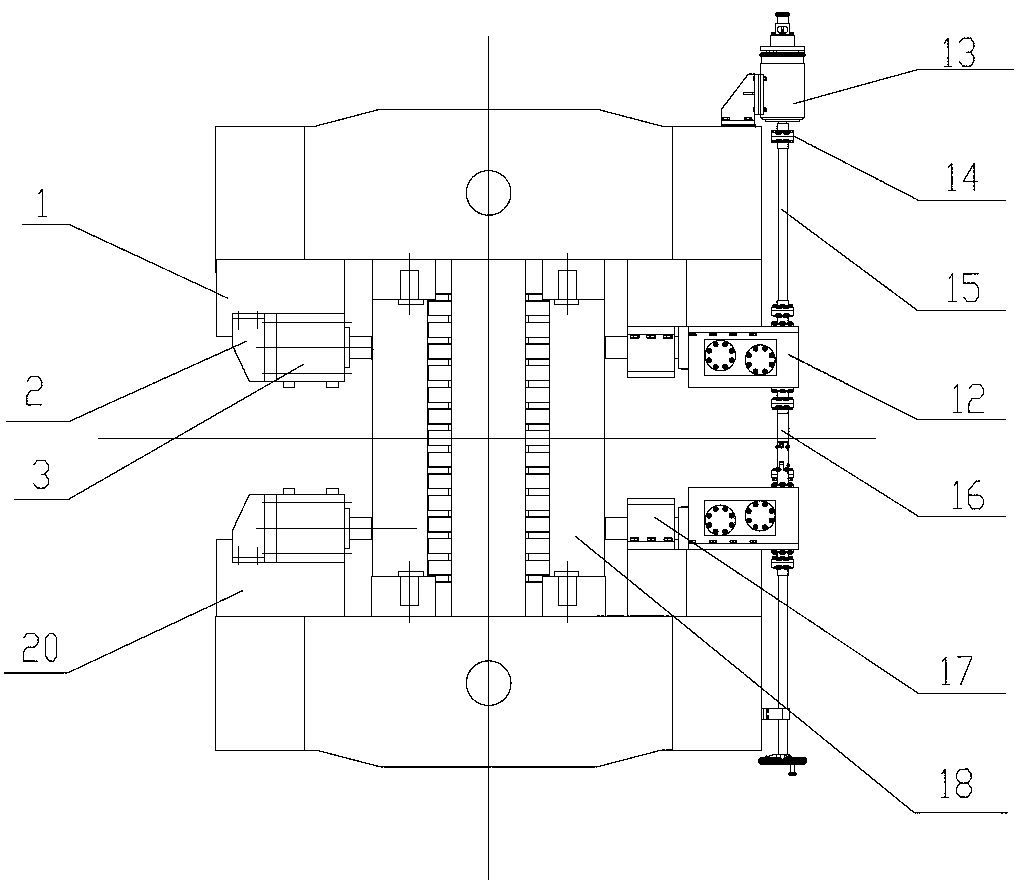

[0011] Such as figure 1 , figure 2 As shown, the first archway 1, oil cylinder base 2, jacking cylinder 3, backing roll 4, side support roll 5, intermediate roll 6, work roll 7, support roll 8, pin 9, jacking rod 10, jacking ramp Iron 11, worm gear box 12, worm gear box motor 13, first coupling 14, connecting rod 15, second coupling 16, guide sleeve 17, backing beam 18, intermediate roller bearing housing 19, second archway 20, Trapezoidal slide block 21 etc.

[0012] Such as figure 1 , figure 2 As shown, the present invention is an oil cylinder slant iron adjustment device for the side support of the work rolls of an 18-high rolling mill, including a first archway 1, a second archway 20, eight backing rollers 4, four side support rollers 5, two Intermediate roll 6, two work rolls 7, and two support rolls 8, wherein the work roll 7 is supported by the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com