A temperature regulation system for condensed water in cooling pool in casting

A technology of temperature adjustment and adjustment system, which is applied in the field of temperature adjustment system, can solve the problems of prolonging the cooling time of castings, increasing cooling costs, waste of water resources, etc., and achieve the effects of shortening cooling time, improving quality, and saving condensation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

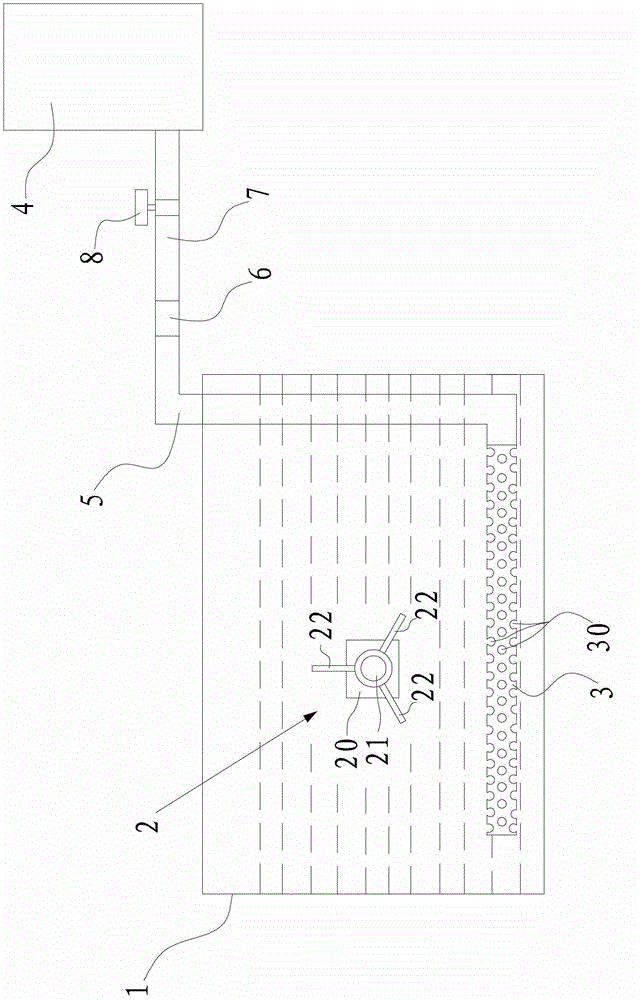

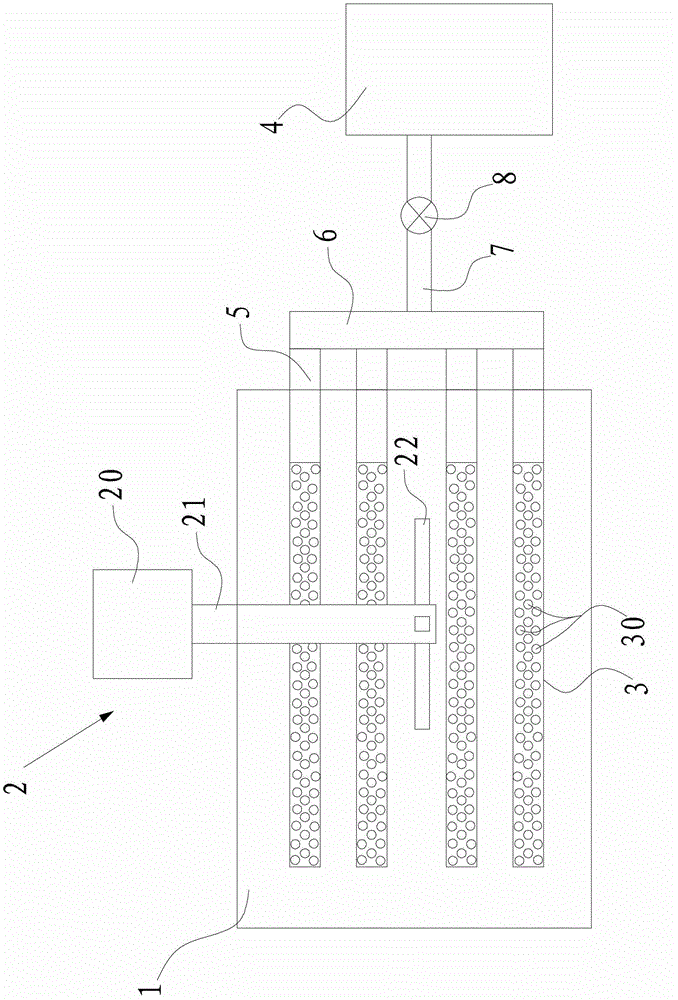

[0017] Such as figure 1 As shown, the temperature regulating system for the condensed water in the cooling pool in the casting of this embodiment includes a stirring device 2 arranged in the cooling pool 1, a plurality of air holes 30 arranged at the bottom of the cooling pool 1 and a plurality of air holes 30 on the surface. Conduits 3, and an air supply source 4 that feeds compressed air into the plurality of conduits 3.

[0018] The above-mentioned plurality of conduits 3 are horizontally and evenly distributed along the length or width direction of the cooling pool 1 . In this example, a plurality of conduits 3 are respectively arranged along the length direction of the cooling pool 1, which not only improves the uniformity of distribution of the high-temperature condensed water, but also shortens the cooling time of the high-temperature condensed water.

[0019] At the same time, in this example, the adjustment system also includes one-to-one corresponding to one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com