Method for dismantling large-section concrete box girders and hoisting device

A technology of concrete box girder and hoisting device, which is used in transportation and packaging, load hanging components, building maintenance, etc. The effect of reducing and reducing risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

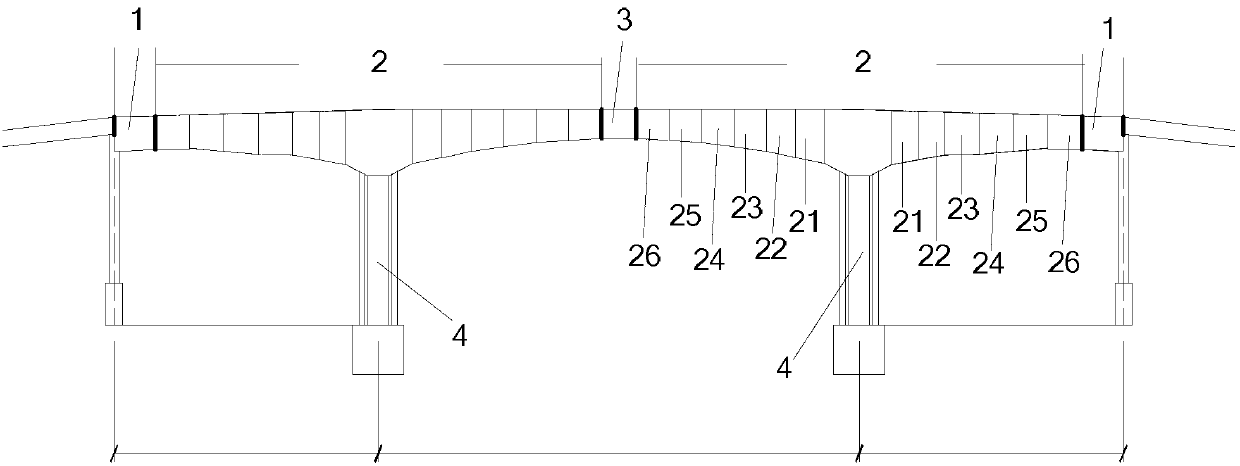

[0031] Please refer to figure 1 , the present invention provides a method for dismantling a large-section concrete box girder, the concrete box girder is supported by several steel pipe columns 4, the concrete box girder includes a closing section 3 and an independent section 2, and the independent section 2 is connected to the The steel pipe column 4 is connected, and each independent section is divided into two halves by a steel pipe column 4, the independent sections 2 are connected by the closing section 3, and the two ends of the concrete box girder are connected by two Each balance segment 1 is connected to the outside, and the two balance segments 1 are connected to the independent segment 2 at the corresponding position.

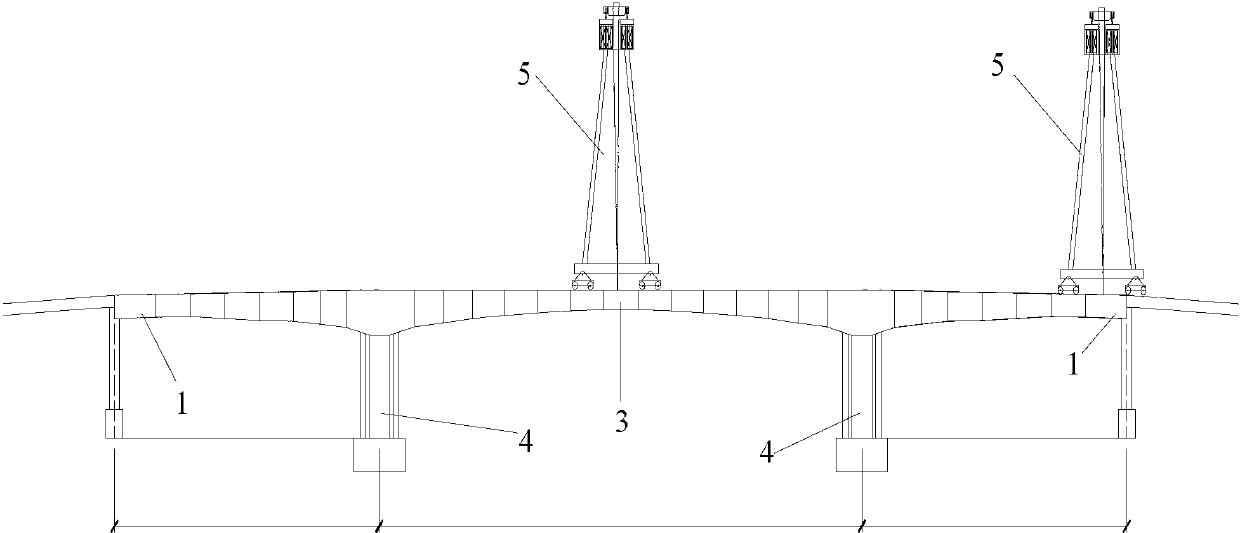

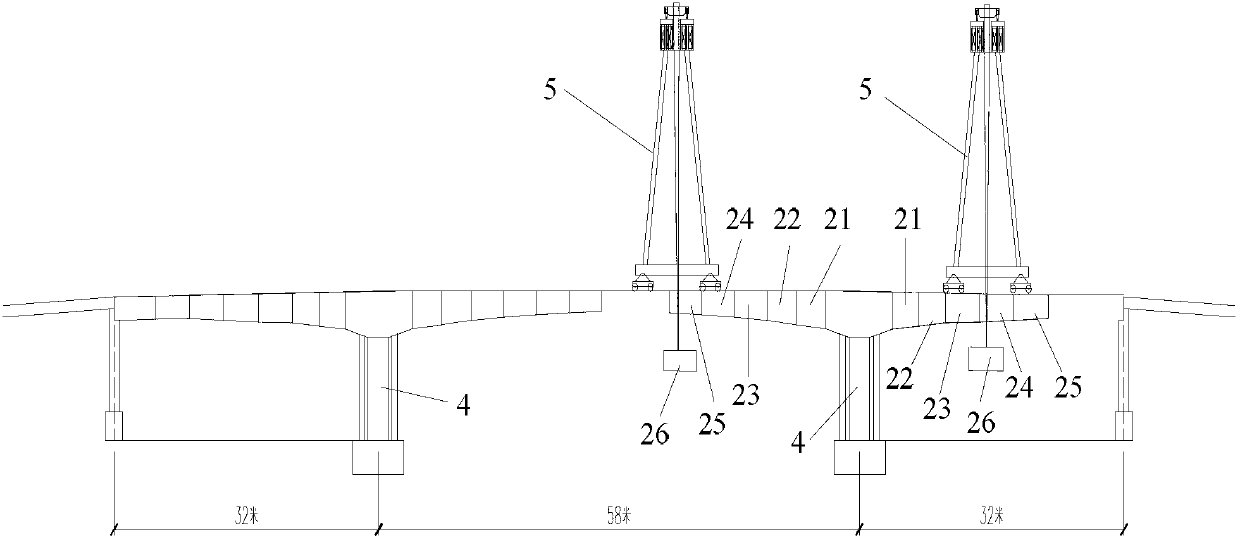

[0032] Please refer to figure 2 with image 3 , and combined with figure 1 , the removal method includes:

[0033] First, remove the closed section 3 or the balanced section 1 at both ends of one of the independent sections 2;

[0034] Then, cu...

Embodiment 2

[0046] Please refer to Figure 10 , the difference between this embodiment and embodiment 1 is that when the cutting segment is divided into three segments, the distribution direction of the three segments of each cutting segment is along the horizontal direction and along the axial direction of the beam set up.

[0047] In summary, the present invention solves the problems of heavy hoisting weight of large-section concrete box girders, high hoisting site and mechanical requirements by reasonably subdividing large-section box girders, and reduces the risk of concrete box girder hoisting. The special steel structure hoisting tool of the invention is suitable for hoisting concrete box girders with special-shaped cross-sections after cutting, and has strong field operability and high hoisting reliability. The invention not only realizes the symmetrical cutting of the concrete box girders at both ends of the independent section, but also further divides the cutting section during...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com