Mounting method of Larsen steel plate pile crown beam

A technology of Larsen steel sheet pile and installation method, which is applied in sheet pile wall, excavation, construction, etc., can solve the problems of heavy workload, increased construction period, waste of three materials, etc., and achieves convenient transportation and installation, and enhances bending stiffness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

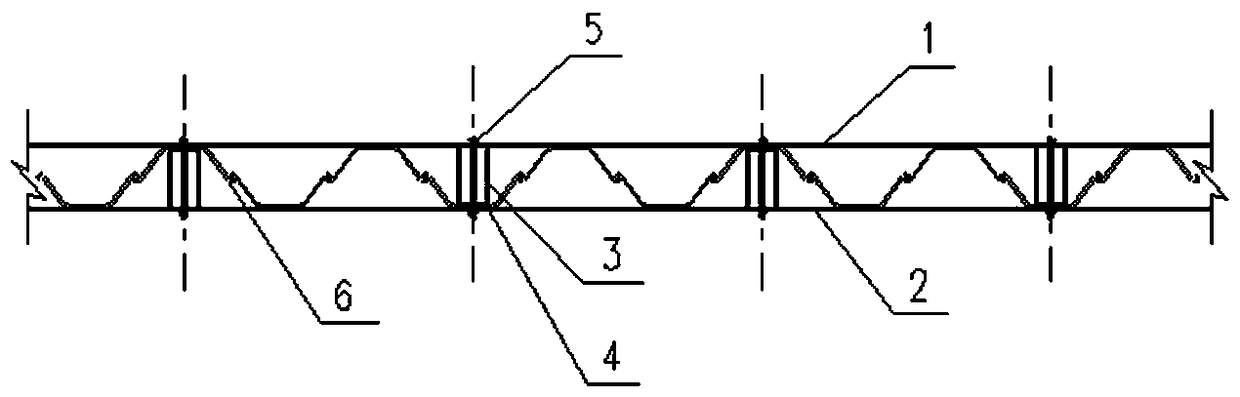

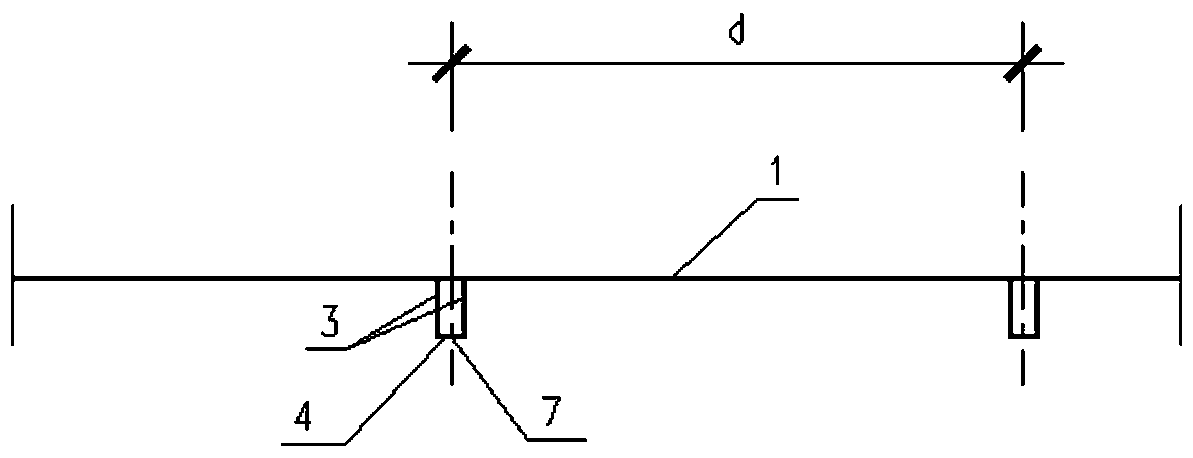

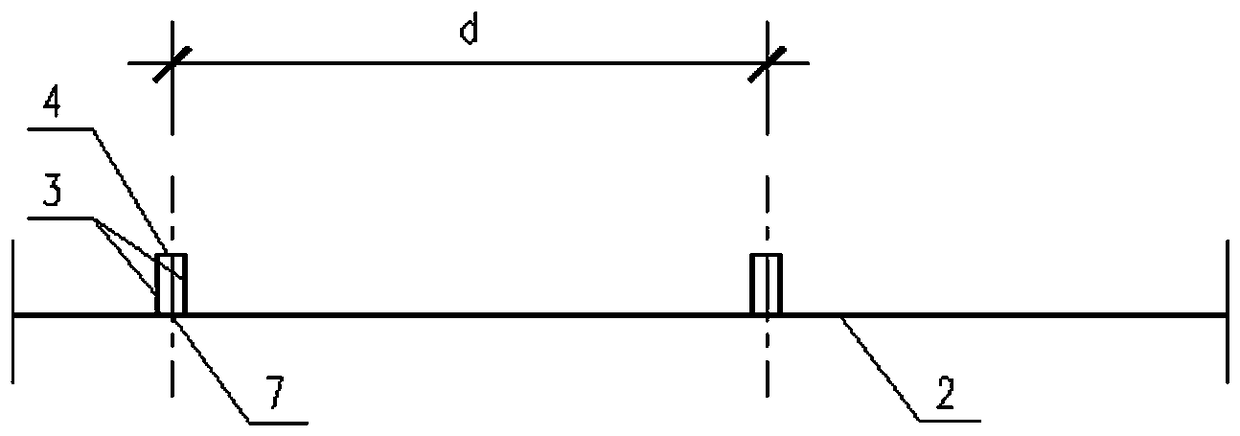

[0023] The design of a foundation pit in Shanghai adopts 400*170 type Larsen steel sheet pile as the enclosure structure. The top of the steel sheet pile is equipped with a crown beam. The inner and outer steel plates are 500mm*14mm, and the side plates of the reinforcing ribs are 310mm*400mm*12mm steel plates. The end plates are made of 250mm*400mm*12mm steel plate, the spacing of the reinforcing ribs is 2.4m, the tension bolts are 2*M20, and the vertical spacing is 300mm. After the outer steel plate and the inner steel plate are welded with the reinforcement ribs, they are arranged alternately by the tension bolts to form a crown beam with a width of 368mm, a height of 500mm, and a rib spacing of 0.8m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com