Multifunctional steel wire rapid moving calibration bar

A multi-functional and fast technology, applied in construction, building construction and other directions, can solve the problems of weakening the advantages of mechanization period, the advantages of scale and economic benefits cannot be fully reflected, and the investment of skilled workers is large, and achieves the effect of convenient and quick setup.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

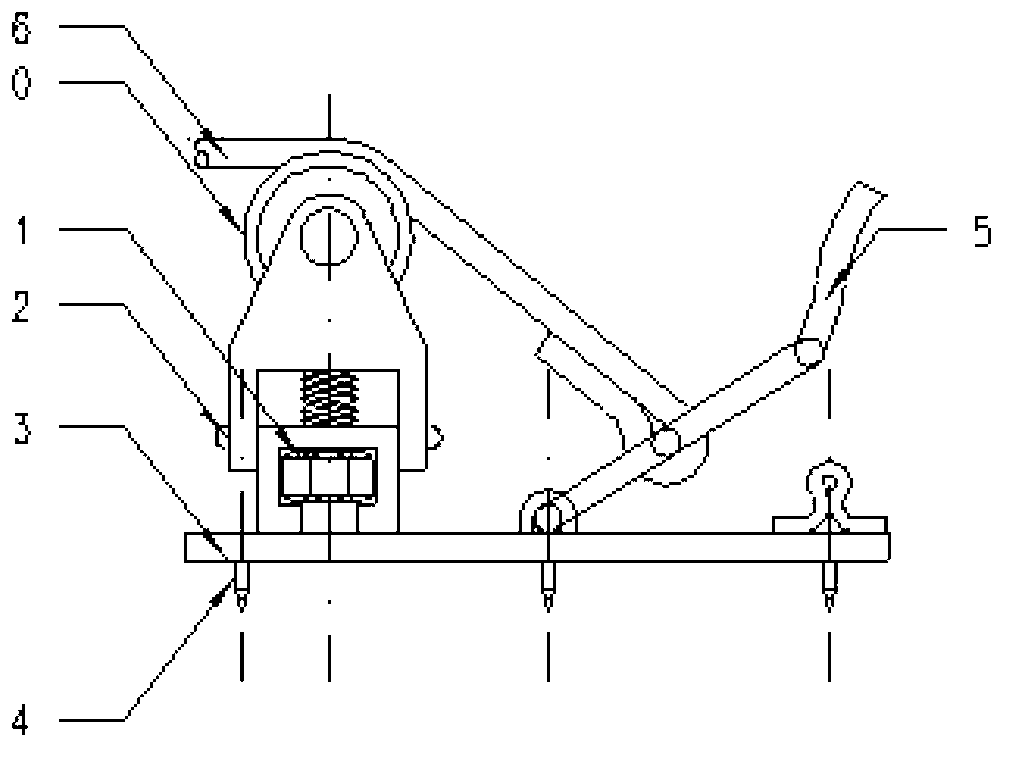

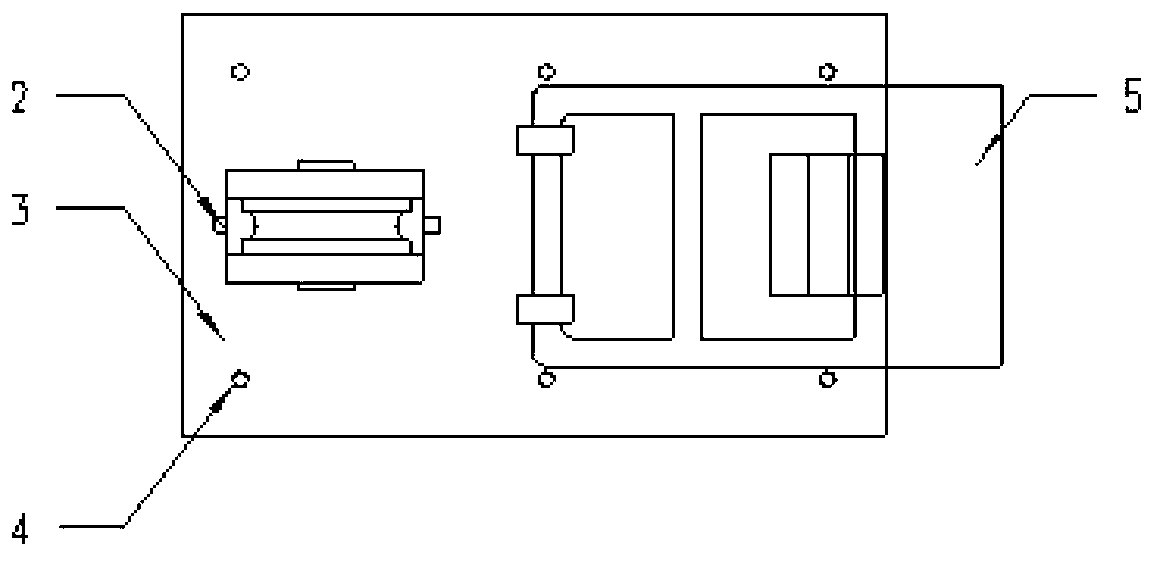

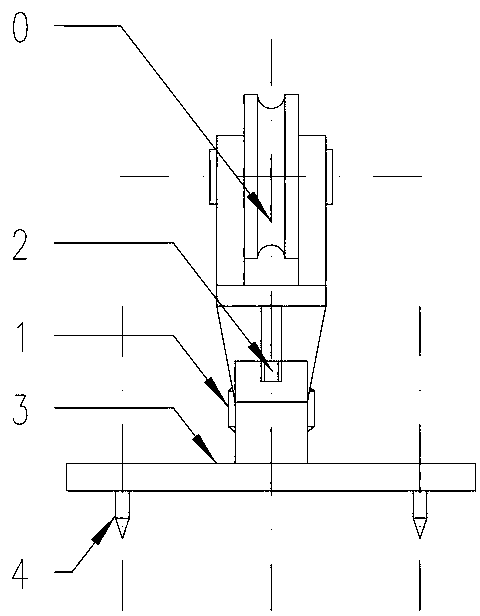

[0023] The structure of the multifunctional steel wire fast movable marking bar of the present invention is described in conjunction with the accompanying drawings.

[0024] Such as Figure 1-7 As shown, the multifunctional steel wire fast movable marking bar of the present invention, said fast movable marking bar includes a plurality of fixed supports 7 correspondingly arranged at equal intervals on both sides, and equal intervals between each corresponding fixed support 7 A plurality of sliding supports 8 are provided, and are connected by steel wire ropes 6. The two ends of the steel wire ropes 6 are fixed on the fastening wrenches 5 of the two fixed supports 7, and the steel wire ropes 6 slide through the fixed supports 7 and the sliding supports 8. The wheel 0 is supported, and the apex of the wire rope 6 is higher than the flange of the sliding wheel 0. When plastering, make the scraper scrape the plastering surface layer along the steel wire surface.

[0025] The fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com